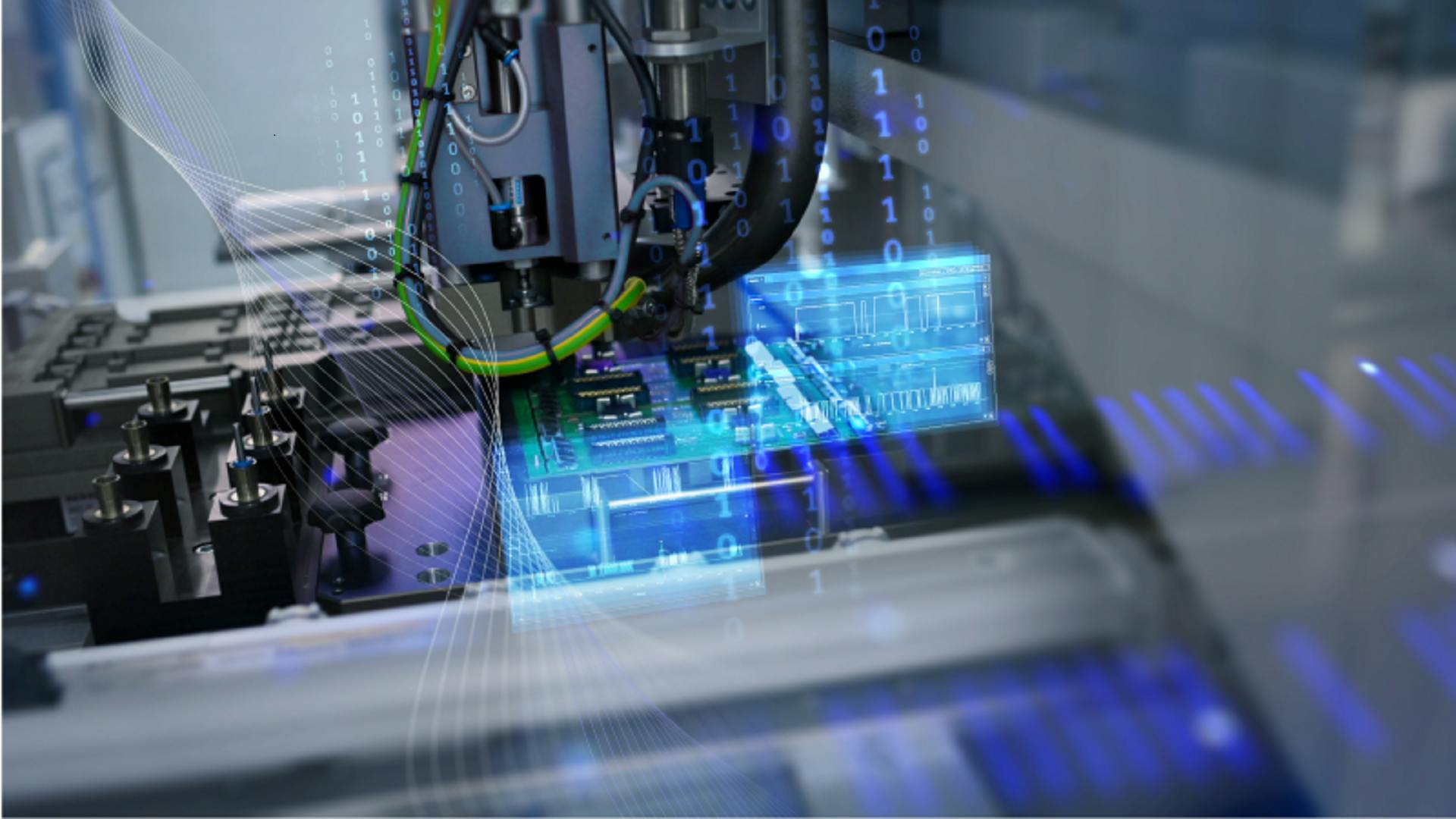

Designing consumer products with complex electronics requires close collaboration between electro-mechanical engineering teams. With electronics manufacturers facing unprecedented fast-paced design cycles, they need to manage innovation, variation and complexity. Changes one domain makes can significantly impact the design of others. Without a single source of truth shared across domains, the result is frustrated engineers, multiple design iterations, increased costs and delayed products. Electronics manufacturers must practice concurrent engineering that leverages model-based systems engineering strategies to reduce these iterations and get to market faster. Learn more about adopting collaborative design workflows in this on-demand webinar.