HEEDS accélère le processus de développement de produits en automatisant les flux de travail d'analyse, en maximisant les ressources matérielles et logicielles de calcul disponibles et en explorant efficacement l'espace de conception pour des solutions innovantes, tout en évaluant les nouveaux concepts pour s'assurer que les exigences de performance sont respectées.

Activez l'automatisation des processus

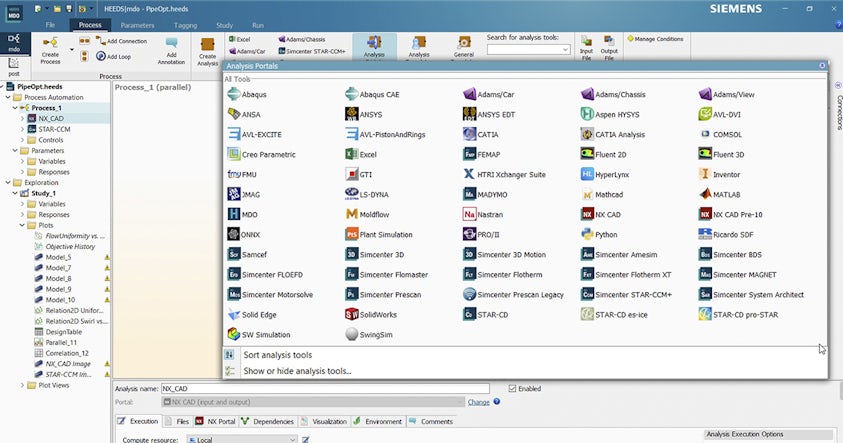

HEEDS permet des flux de travail automatisés pour faciliter les processus de développement de produits. Avec une liste fournie d'interfaces développées avec des outils commerciaux de conception assistée par ordinateur (CAO) et d'ingénierie assistée par ordinateur (IAO), HEEDS intègre rapidement et facilement de nombreuses technologies sans script personnalisé. Les données sont automatiquement partagées entre différents produits de modélisation et de simulation pour évaluer les compromis de performance et la fiabilité de la conception.

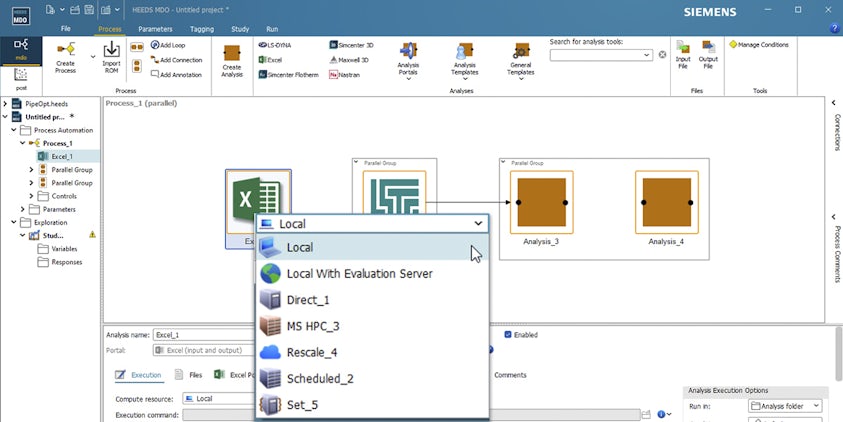

Utilisez l'exécution distribuée

HEEDS tire parti des investissements matériels existants, en utilisant efficacement toutes les ressources matérielles disponibles. Utilisez des postes de travail ou des clusters Windows et Linux, sur site ou à l'étranger, ainsi que des ressources de cloud computing pour accélérer le développement de produits innovants.

Par exemple, les modifications de géométrie peuvent être automatisées sur un ordinateur portable avec le système d'exploitation Windows ; une simulation de déformation structurelle peut être effectuée sur un poste de travail Linux ; et une simulation de la mécanique des fluides numérique (MFN) peut être effectuée sur plusieurs cœurs d'un cluster Linux ou du cloud.

Débloquez une recherche efficace

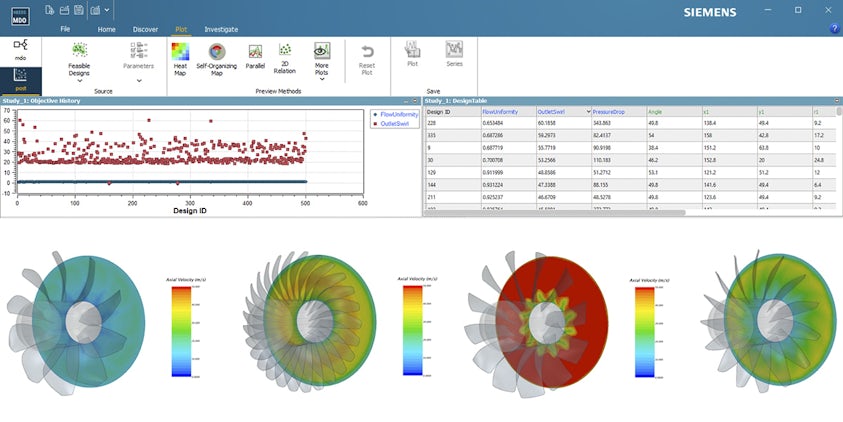

Tous les concepteurs et ingénieurs peuvent utiliser HEEDS pour exploiter le pouvoir de l'innovation, contrairement à la plupart des outils d'optimisation traditionnels qui nécessitent une expertise technique hautement spécialisée et la simplification des modèles pour permettre une recherche efficace.

HEEDS comprend une fonctionnalité propriétaire d'exploration de l'espace de conception pour trouver efficacement des concepts de conception qui répondent ou dépassent les exigences de performance. HEEDS adapte automatiquement sa stratégie de recherche à mesure qu'il en apprend davantage sur l'espace de conception afin de trouver la meilleure solution dans le délai consacré. Il est facile à utiliser, conçu pour respecter les délais et peut apporter une valeur ajoutée significative.

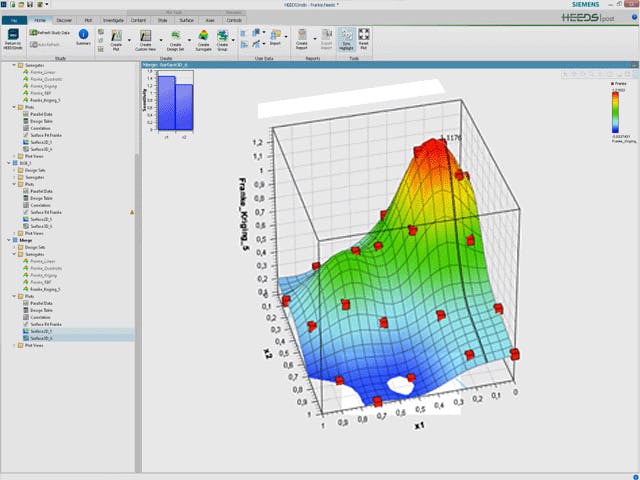

Obtenez des informations et faites des découvertes

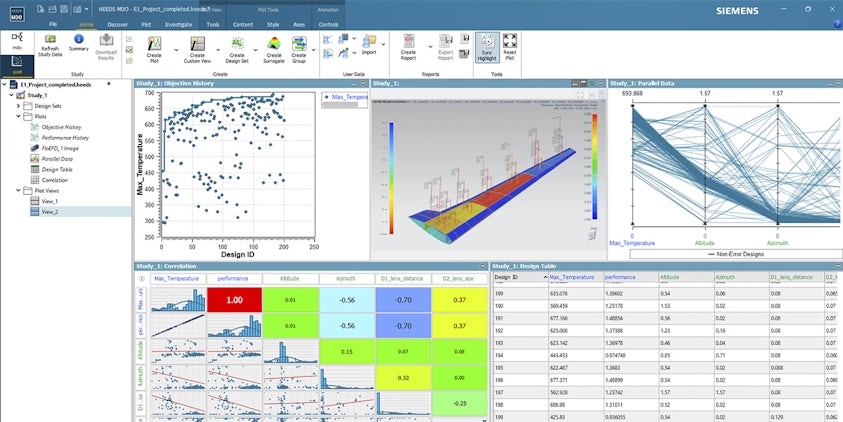

HEEDS offre la possibilité de comparer facilement les performances sur un large éventail de conceptions présentant des caractéristiques et une fiabilité recherchées. Le logiciel aide les utilisateurs à visualiser les compromis de performance de conception entre des objectifs et des contraintes concurrents avec divers graphiques, tableaux, schémas et images pour mieux comprendre et découvrir des solutions innovantes. Cela facilite le développement de conceptions prêtes pour la production en mettant en place un véritable jumeau numérique.

What's new in HEEDS 2310?

Uncover how the new functionalities in HEEDS 2310, such as a new novel AI integration, data import enhancements, and refined portal version management will lead you to discover better designs, even faster!