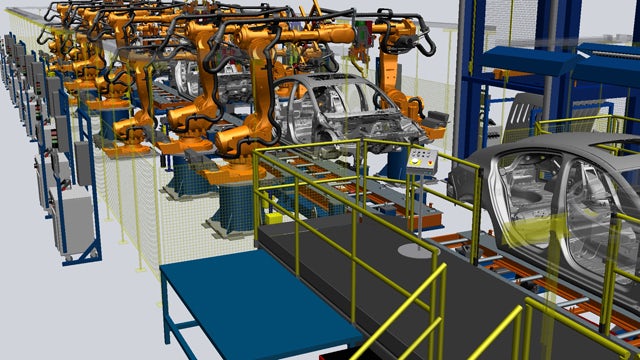

Améliorez vos plans de processus de fabrication

Créez et gérez la nomenclature de fabrication et la nomenclature de processus pour déterminer ce qu'il faut fabriquer et comment le fabriquer, générer des instructions de travail pour l'atelier, effectuer une analyse détaillée des temps d'opération, équilibrer les lignes de production et bien plus encore, tout en assurant une collaboration étroite entre les équipes d'ingénierie, de fabrication et d'exécution.

BSH Home Appliance

Les logiciels Tecnomatix et Teamcenter Easy Plan aident les fabricants à atteindre plus facilement leurs objectifs d'efficacité de production et leurs objectifs commerciaux.

Leveraging an open, web-based, easy-to-use solution to standardize process planning across plants

Société:BSH Home Appliances

Secteur d'activité:Produits de grande consommation et Distribution

Lieu:Munich, Germany

Siemens Software:Teamcenter, Tecnomatix

Logiciel de planification d'assemblage Teamcenter Easy Plan

Easy Plan est une solution web orientée tâches pour la planification des processus de fabrication.

Regardez cette vidéo de démonstration pour en savoir plus.

Explorez les produits de planification des processus de fabrication

Exécutez plus efficacement les activités de fabrication de pièces, de planification de l'assemblage de produits et de disposition de la fabrication grâce à la gestion complète des données et à la collaboration en utilisant la gamme de produits de planification des processus de fabrication.