Tirez parti de l'accès aux données en direct

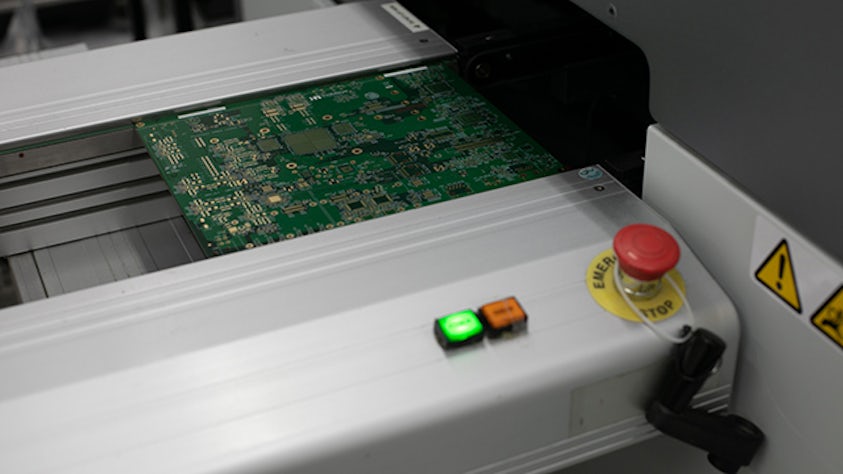

Optimisez l'efficacité du flux de données grâce à la normalisation automatique de toutes les données de l'atelier. Opcenter Connect Electronics recueille des données en direct de chaque processus ou machine de l'atelier en combinant et en normalisant l'acquisition de données logicielles unifiées et modulaires. Cette solution favorise ainsi un flux de données complet entre l'atelier et les applications internes, ce qui réduit le temps et les efforts fournis.