Concevoir, optimiser et chiffrer les processus de fabrication

Conception de formboards de faisceaux

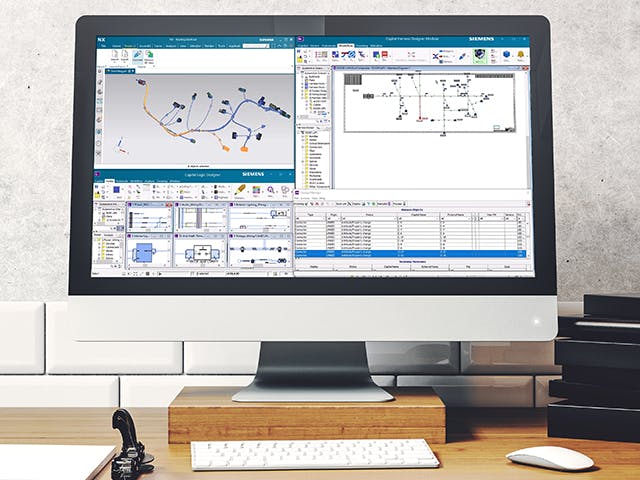

Grâce à Capital, les concepteurs de formboards peuvent créer une disposition optimisée et ergonomique basée sur un retour d'information dynamique sur les efforts/temps de travail liés à chaque composant.

Planification du processus de fabrication des faisceaux

Utiliser Capital pour saisir et appliquer les techniques de meilleures pratiques aux tâches de planification du processus de fabrication des faisceaux de câbles et d'estimation des coûts.

Documentation sur la fabrication des faisceaux

La qualité de la documentation sur la fabrication est essentielle pour minimiser les erreurs. Créez une documentation sur la fabrication directement à partir des données d'ingénierie des faisceaux et de la séquence définie du processus d'assemblage.

Tirer parti du jumeau numérique pour accroître la productivité

Tirez parti d'un jumeau numérique avec Capital pour transformer les performances de votre entreprise en matière d'ingénierie, de calcul des coûts et de fabrication. Éliminez les erreurs de documentation, réduisez les coûts de création et, en fin de compte, augmentez les bénéfices.

Optimiser les processus et améliorer l'efficacité de la production

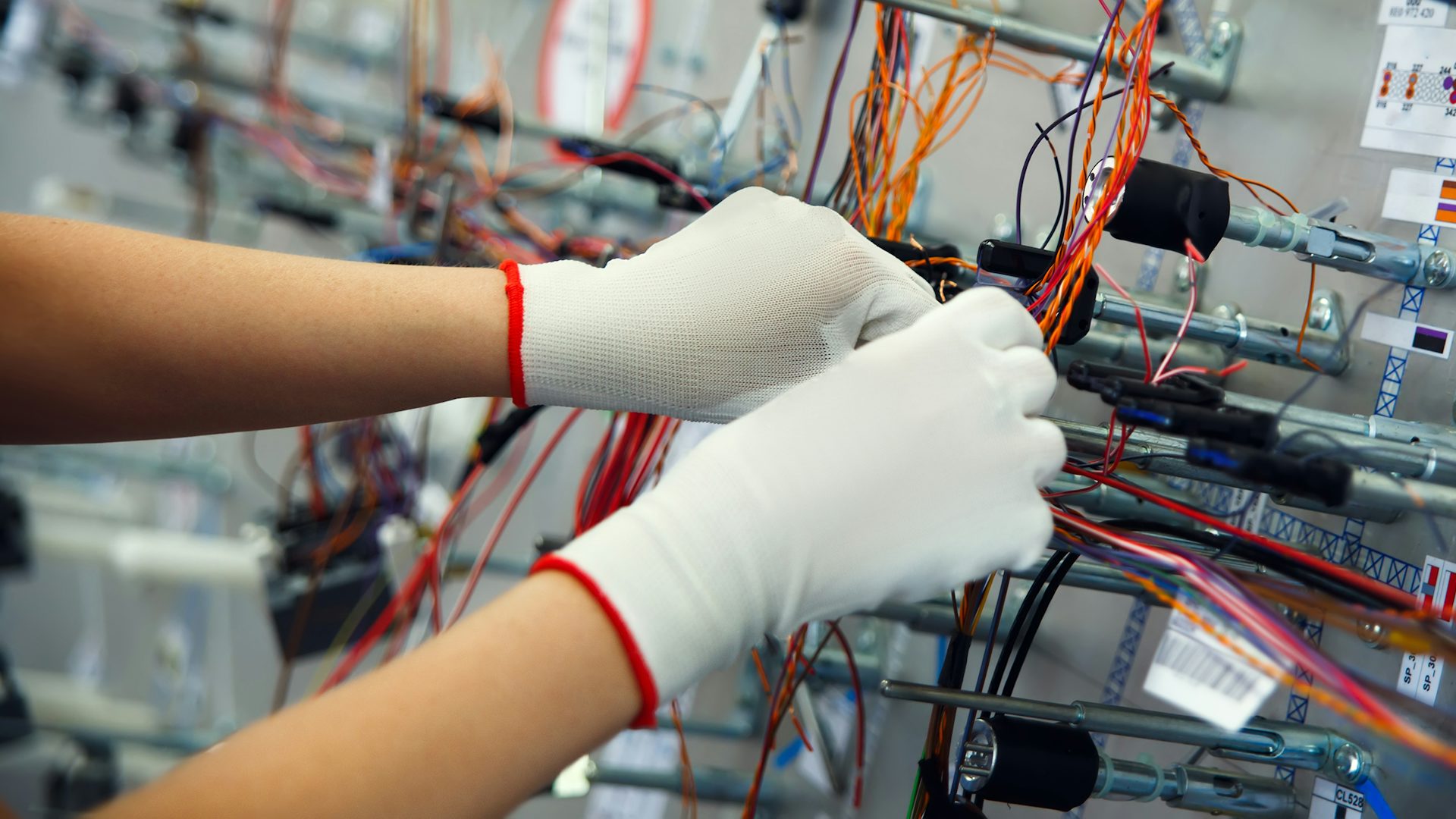

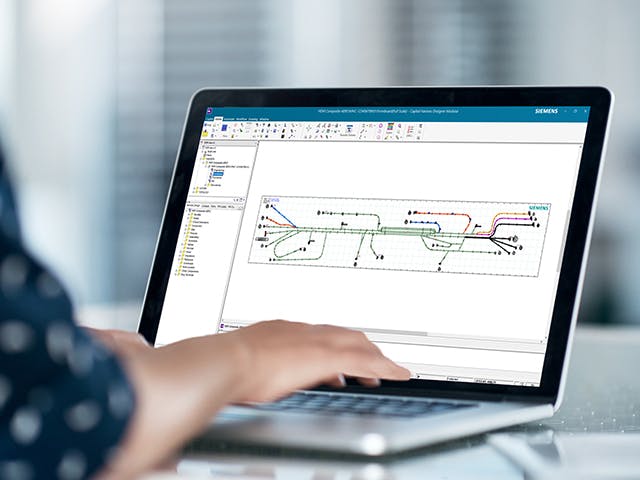

Les conceptions de faisceaux entièrement détaillées et améliorées sont souvent documentées dans une mise en plan de faisceau en 2D et non à l'échelle. Les ingénieurs de fabrication utilisent ensuite ces informations pour créer une représentation à l'échelle réelle des données de conception des faisceaux, enrichie d'informations de fabrication supplémentaires, appelée mise en plan de formboard.

Outre les composants du faisceau de câbles, tous les objets utiles à la fabrication, tels que les fourches de faisceau, les porte-connecteurs, les porte-clips ou les indicateurs de position de bande, sont représentés graphiquement sur ces mises en plan de formboard, ce qui constitue une aide visuelle pour les opérateurs. Le puissant environnement graphique et de gestion des conceptions de formboard de Capital permet aux ingénieurs de fabrication de créer rapidement des diagrammes de formboard à grande échelle, détaillés et prêts pour la fabrication.

Capital guide les concepteurs de formboard dans la création d'une disposition optimisée et ergonomique basée sur un retour d'information dynamique sur les efforts/temps de travail liés à chaque composant dans une zone particulière du tableau. Les concepteurs peuvent également créer et gérer des formboards fusionnés ou combinés pour une utilisation efficace des lignes de production et de l'espace de l'usine.

Créer une documentation de fabrication des faisceaux

Compte tenu de la complexité des faisceaux d'aujourd'hui, il est essentiel de pouvoir créer automatiquement des instructions pour l'opérateur et des aides visuelles pour chaque installation de conception et de production.

La qualité de la documentation sur la fabrication est essentielle pour minimiser les erreurs. Créez de la documentation directement à partir des données de faisceau d'ingénierie et des séquences de processus d'assemblage définies.

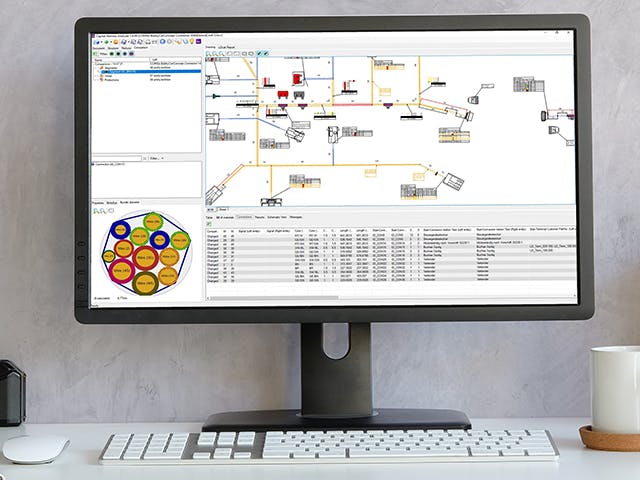

Rationaliser la planification et l'optimisation de la fabrication des faisceaux

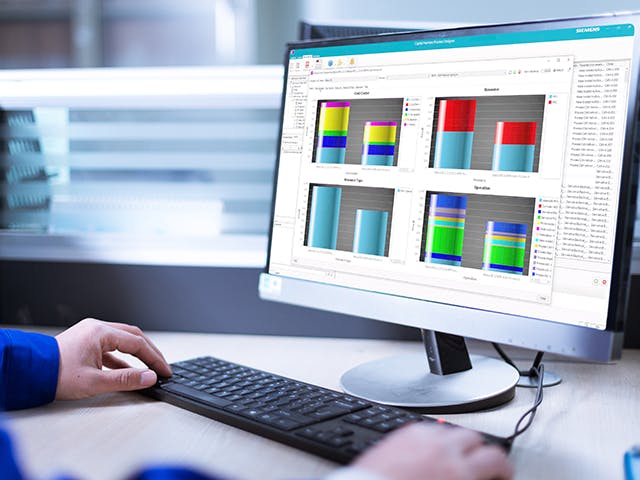

Les ingénieurs en processus de fabrication sont souvent confrontés au défi de déterminer un modèle efficace d'étapes de processus séquencées qui aboutissent à l'assemblage correct du faisceau cible. En général, il existe plus d'un modèle possible. Le choix optimal dépend des capacités de production spécifiques de l'usine ou des usines en question. Capital facilite la création automatique d'un schéma de fabrication efficace pour chaque faisceau à construire. Pour ce faire, les conceptions de faisceaux sont décomposées en fonction des descriptions des capacités de fabrication précédemment saisies, à l'aide d'un moteur de raisonnement qui intègre la logique d'assemblage des faisceaux de câble.

Utiliser Capital pour saisir et appliquer les techniques de meilleures pratiques aux tâches de planification du processus de fabrication et d'estimation des coûts. Il facilite la planification rapide et précise des processus, ce qui permet aux ingénieurs de disposer de plus de temps pour créer de multiples scénarios de simulation qui seront comparés les uns aux autres et analysés en vue d'optimiser la fabrication. Les ingénieurs de production peuvent tirer parti des capacités offertes par Capital pour concevoir des lignes de production efficaces, utiliser les ressources de fabrication existantes aussi efficacement que possible et réagir rapidement à de nouvelles situations telles que des changements de taux de prise. Il permet de prendre de meilleures décisions dans l'atelier et, en fin de compte, de réduire le temps nécessaire à la rentabilité.