Auto manufacturer uses Simcenter 3D and Simcenter Tecware to verify and validate durability virtually

Siemens Digital Industries Software solutions help Fiat reduce overdesign and cut costs

Fiat

Fiat has been manufacturing automobiles since 1899, and has grown through numerous acquisitions and partnerships. It bought Lancia in 1968, became a shareholder of Ferrari in 1969, took control of Alfa Romeo from the Italian government in 1986, purchased Maserati in 1993 and became the majority shareholder of Chrysler in 2011.

http://www.fiat.com/- Headquarters:

- Turin, Italy

- Products:

- Durability, Simcenter Products, Tecware

- Industry Sector:

- Automotive & transportation

I am confident that Simcenter Engineering Services has the competencies to be our engineering partner for future development projects.

Fiat Group Automobiles S.P.A.

Improving predictive capabilities

Fiat Group Automobiles S.P.A (Fiat) has been designing and manufacturing automobiles since 1899, so when the company says that there is a clear shift in the way cars are designed, it is a good idea to listen to them. Fiat believes that using simulation significantly improves its predictive capabilities, enabling the company to produce more precise models that facilitate informed tradeoffs between performance and weight, thereby better defining costs.

As such, Fiat wanted to be able to predict road loads in the concept phase, with the aim of providing input to designers prior to a prototype being developed. They also wanted to be able to explore the car behavior for fatigue and misuse.

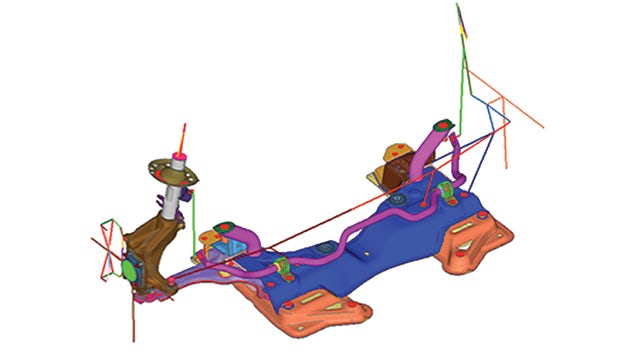

Further, the company needed to be able to produce virtual designs and reliable models that could be used in the vehicle development process. To obtain an accurate load prediction, it is necessary to have precise multi-body models. This is accomplished by validating subsystems, components and the full vehicle model virtually (for example, using kinematics and compliance), and predicting and validating performance based on actual operational conditions on the test track.

Finally, Fiat wanted to compare and correlate its European and North American durability programs, so it developed an equivalency between its proving grounds in Balocco, Italy and Chelsea, Michigan in the United States.

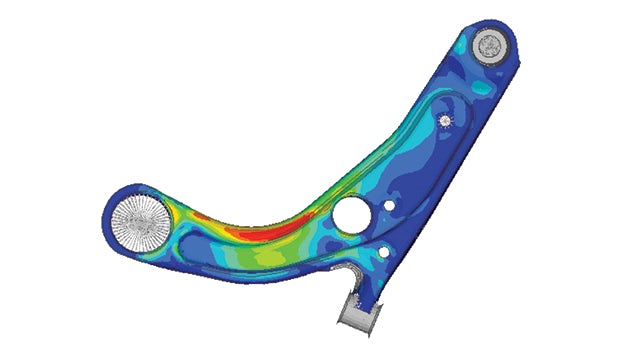

Fiat was able to achieve these goals with the help of Siemens Digital Industries Software by using the durability applications of Simcenter™ 3D software and Simcenter™ Tecware software. Simcenter 3D enables Fiat to design automobiles for optimal durability performance. It is an integrated solution for designing lightweight, reliable and fatigue-resistant products right from the start. It is used to predict fatigue hotspots on the component and the full system, and is a significant help in making the right design decisions early in the development process.

Simcenter Tecware is used in durability engineering to gain a precise understanding of the loads that products will undergo during their anticipated lifetime. The availability of realistic load data is essential for virtual and physical product validation and optimization. Simcenter Tecware is a modular suite of solutions for durability load data processing.

With Simcenter Tecware, a user can streamline the process of consolidating acquired load data, analyzing durabilityspecific characteristics and preparing for reliability simulations, proving ground and rig test campaigns without requiring any cryptic commands or writing complex programs. As a result, engineers can gain more accurate insights into the durability performance of new product designs throughout the development process.

These solutions have enabled Fiat to enhance its inputs to achieve correct dimensioning, which has allowed the company to achieve optimal weight, faster time-to-market and a higher-quality product. It has also resulted in lower costs for prototype development and more accurate simulation results, leading to the best possible tradeoff between performance and weight.

“I am confident that Simcenter Engineering Services has the competencies to be our engineering partner for future development projects,” says Marco Spinelli, head of the chassis computer-aided engineering (CAE) department at Fiat.

Proving grounds in Chelsea, Michigan.

Providing early input

The Circuito di Balocco test track is located 60 kilometers northeast of Fiat’s headquarters in Turin, Italy. It is the primary proving ground of the Fiat Group, as well as the preferred proving ground for the European market. The Circuito di Balocco test track was built in the early 1960s by Alfa Romeo for testing new cars, prototypes and racing cars. The track area exceeds 5 million square meters and has over 65 kilometers of different types of test tracks. The Balocco proving grounds represents the worst-case scenario for European drivers with a mix of rough roads, obstacles and tracks that require high lateral acceleration.

For the North American market, Fiat uses the proving grounds in Chelsea, Michigan, 93 kilometers west of Detroit. The Chelsea Proving Grounds cover an area of 15.6 square kilometers, has 160 lane kilometers of on- and off-road test surfaces, and includes the following test areas: sledimpact testing site, covered crash barrier, skid traction area, mileage accumulators, emissions certification center, wind tunnel, corrosion testing facility, curb hit testing, and 32 and 15 percent grades. A new hard-cornering road is being constructed.

Since the requirements in the United States are different than in the European Union (EU), the Chelsea Proving Grounds provide a test that is more suitable for worst-case customer usage in North America, including trips over rugged terrain.

Fiat used Simcenter Tecware to develop an equivalency between the tracks by analyzing durability-specific characteristics (such as loads predicted using simulation from time domain to statistics, rain flow, level crossing and range pair) and power spectral density (PSD); performing correlations between measurement and simulation (such as overlaying statistics, level crossing, PSD and fatigue damage comparison); combining different track features (such as repetition factors) and generating an overall durability schedule.

Proving grounds in Turin, Italy

Developing versatile proving grounds

The keys to success for Fiat started with its long-time partnership with Siemens Digital Industries Software. The Simcenter products had previously been validated at Fiat, so the company knew that Simcenter Tecware and Simcenter 3D had all the necessary features for applying its durability methodology. Fiat had found that Simcenter Tecware was easy-to-use and customize, while Simcenter 3D had all the solutions necessary to conduct a complete fatigue analysis.

Fiat has been using Simcenter 3D for durability simulation software for more than a decade, as it provides all the necessary solutions – such as automatic stress gradient influence and weld fatigue methods – to conduct a complete fatigue analysis. Load data can be synthesized and prepared by using Simcenter Tecware, and directly applying it to the fatigue analysis. Fiat especially appreciates the openness of Simcenter 3D for durability simulation for performing customizations, and the direct access it provides to the finite element data for all of the company’s solvers.

By creating an equivalency between the Balocco and Chelsea proving grounds, Fiat can develop a car for worldwide use in either location, which reduces the costs of testing. After having compared and correlated European and American durability programs, the Balocco and Chelsea proving grounds can be used to test Fiat’s durability targets.

“Both our proving grounds are now fully equivalent and interchangeable,” says Spinelli. “It means that Balocco can be used for US or worldwide car development and Chelsea can be used for EU or worldwide car development. Because of this consolidation, there no longer exists an EU or US proving ground; we have two worldwide proving grounds.”

Reducing overdesign

“Although we can’t measure the improvement because we previously didn’t use virtual data, the results that we have received by using both Simcenter products are absolutely excellent,” says Spinelli. “In absolute terms, we have an error in the real loads of between 8 and 15 percent depending on the mission. The main advantage is that we will be able to start with a complete virtual prediction and use experimental data for model validation.”

From a technical standpoint, Fiat is able to perform simulations prior to having a prototype available, which means the team can achieve correct dimensioning and avoid overdesign.

From a process efficiency standpoint, Fiat is able to reduce uncertainty in the initial phase and improve quality in a shorter time while avoiding overdesign at the prototyping stage. This is a big step forward because avoiding problems at the prototype level means there are fewer components to test, and reduced time and costs.

In absolute terms, we have an error in the real loads of between 8 and 15 percent depending on the mission. The main advantage is that we will be able to start with a complete virtual prediction and use experimental data for model validation.

Fiat Group Automobiles S.P.A.