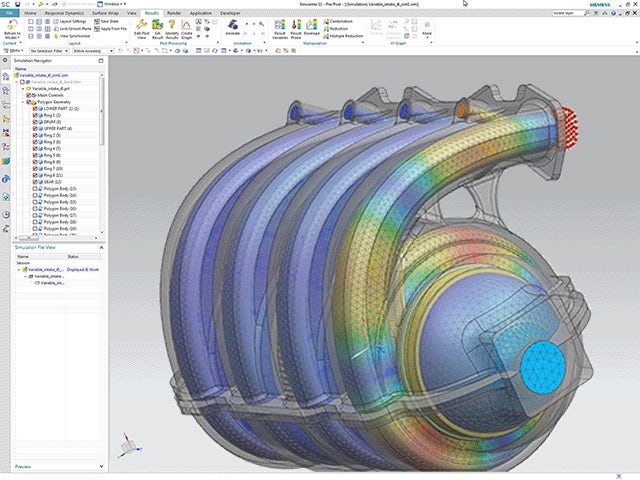

La compréhension et la fourniture de performances inter-domaines nécessitent des solutions de simulation et de test qui peuvent être déployées dans toutes les phases de développement et dans tous les domaines de performance et de physique. De plus, ces activités doivent être liées et non menées indépendamment afin de saisir les phénomènes multiphysiques du monde réel et d’équilibrer les attributs conflictuels. Simcenter propose un portefeuille intégré de solutions de simulation prédictive, de test et d’exploration de conception de premier ordre qui couvrent toutes les phases du processus de développement de produits afin de résoudre les problèmes les plus difficiles de l’ingénierie et de contribuer à transformer l’ingénierie en stimulant la productivité et en favorisant l’innovation.

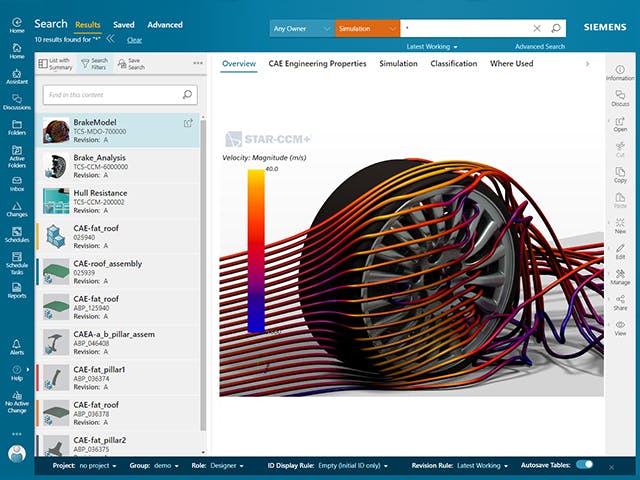

La simulation et les tests ne peuvent plus être considérés comme des activités cloisonnées. Le jumeau numérique apporte de la valeur tout au long du cycle de vie et son évolution doit être gérée pour assurer la traçabilité et l’impact du changement. Cela n’est possible qu’en fournissant des simulations et des tests dans le cadre d’une initiative globale de développement de produits numériques. Siemens Xcelerator brouille les frontières entre les domaines d’ingénierie tels que l’électricité, la mécanique et les logiciels, et les solutions de simulation et de test Simcenter complètent les solutions Siemens Xcelerator dans les phases de conception, de réalisation et d’optimisation du cycle de vie.

Sur la voie de la transformation numérique, les entreprises ont besoin de partenaires fiables disposant des ressources nécessaires pour stimuler en permanence l’innovation dans les outils et les applications. Siemens investit beaucoup dans la recherche et le développement, s’appuie sur des partenariats avec des entreprises établies dans des régions adjacentes et investit dans des start-ups qui possèdent les technologies qui pourraient transformer les entreprises à l’avenir. Tout cela garantit un flux constant d’innovations qui peuvent aider nos clients à rester à la pointe et à réaliser les avantages de la numérisation plus rapidement que leurs concurrents. Les services d’ingénierie et de conseil de Simcenter fournissent une connaissance approfondie du domaine, des installations, des ressources et une expertise pour accélérer la transformation des processus d’ingénierie et le retour sur investissement qui en résulte.