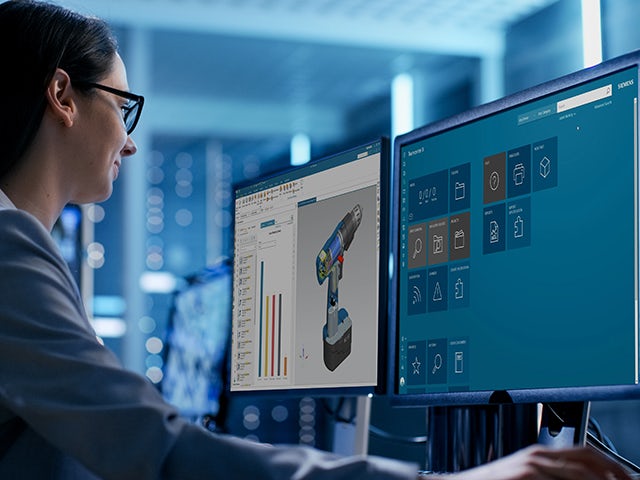

How can PLM on the cloud help you deliver innovative, high-quality products, while keeping costs reasonable and ensuring a fast return on investment?

Implement a PLM solution to build a data and collaboration system that will enable your entire organization to work as a single team, in real time, with one source of truth: from design to prototyping to testing to manufacturing and beyond.