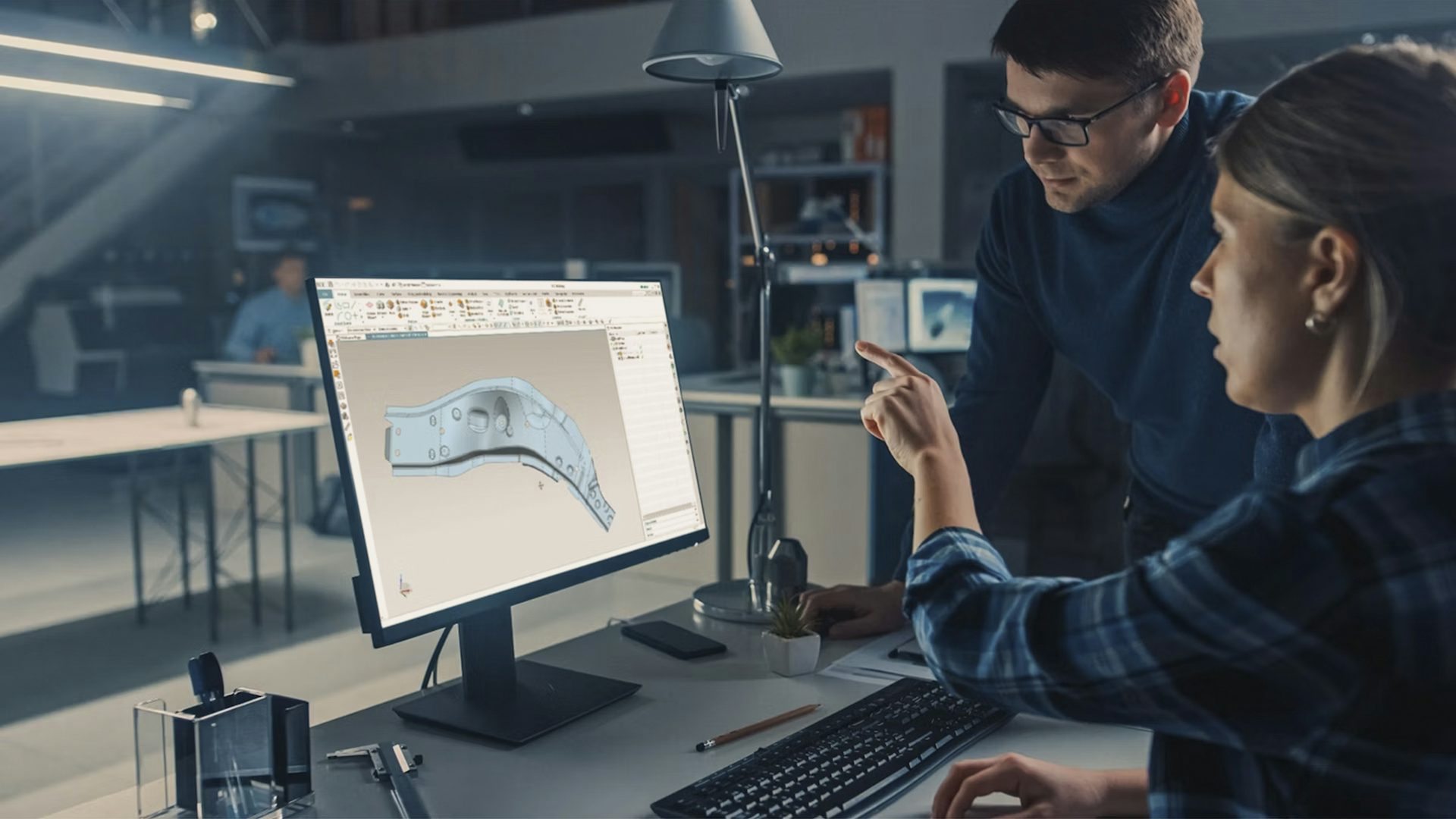

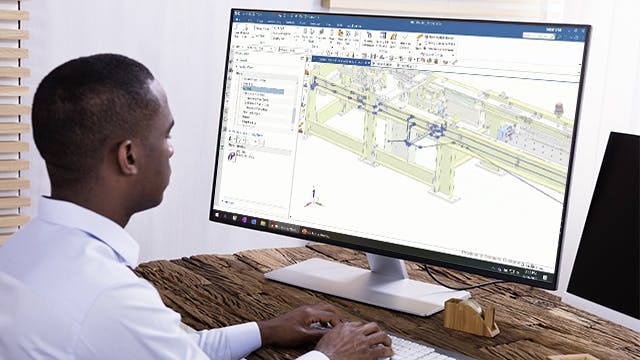

Les clients exigent des produits complexes, de haute qualité et durables qui sont livrés rapidement. Pour rester compétitif, vous devez développer et commercialiser des conceptions innovantes qui répondent aux besoins d’un marché en constante évolution en moins de temps, avec une qualité supérieure, avec moins de problèmes et à des prix compétitifs.

Le problème dans la conception de produits aujourd’hui est que de nombreuses entreprises utilisent encore des systèmes de conception hérités déconnectés qui ne prennent pas en charge une approche holistique de conception de produits de nouvelle génération. Pour réussir, la conception doit être entièrement intégrée à la simulation, à la validation, à la fabrication et au reste du processus de développement du produit.

.jpg?auto=format,compress&w=640&q=60)

.jpg?auto=format,compress&w=640&q=60)