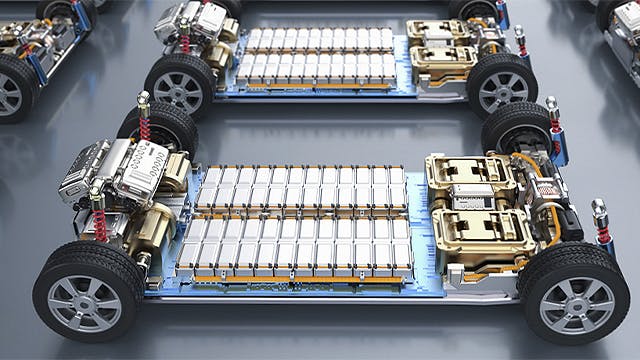

La performance d’un véhicule se rapporte aux capacités, à l’efficacité et à la fonctionnalité globales d’un véhicule, englobant des aspects tels que l’accélération, l’autonomie de la batterie, la sécurité, l’aérodynamique et la gestion de l’eau, les systèmes avancés d’aide à la conduite (ADAS), la gestion de l’énergie et de la chaleur, le bruit, les vibrations et la rudesse (NVH) et l’acoustique, la résistance et la durabilité, les commandes du véhicule et la maniabilité du véhicule.

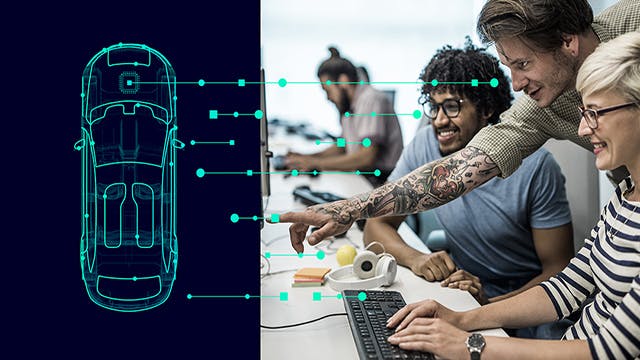

L’ingénierie des performances automobiles est guidée par les exigences de l’entreprise et permet d’optimiser le système de bout en bout grâce à une boucle virtuelle continue de test et de surveillance. À l’aide d’une stratégie de virage à gauche, les constructeurs et les fournisseurs automobiles visent à fournir une meilleure valeur commerciale en découvrant les problèmes potentiels dès le début du cycle de développement. En utilisant la simulation dès le début du processus de conception et en testant virtuellement si les produits répondent aux exigences, ils peuvent détecter les problèmes à un stade précoce et y remédier dans un jumeau numérique compréhensible. De plus, ils peuvent explorer des alternatives de conception plus tôt dans la phase de conception, lorsque la modification des conceptions est plus facile et moins perturbatrice.