Comment pouvez-vous produire des composants de haute précision, de haute qualité, personnalisés et durables dans les délais et à grande échelle, tout en améliorant votre productivité et votre rentabilité globales ?

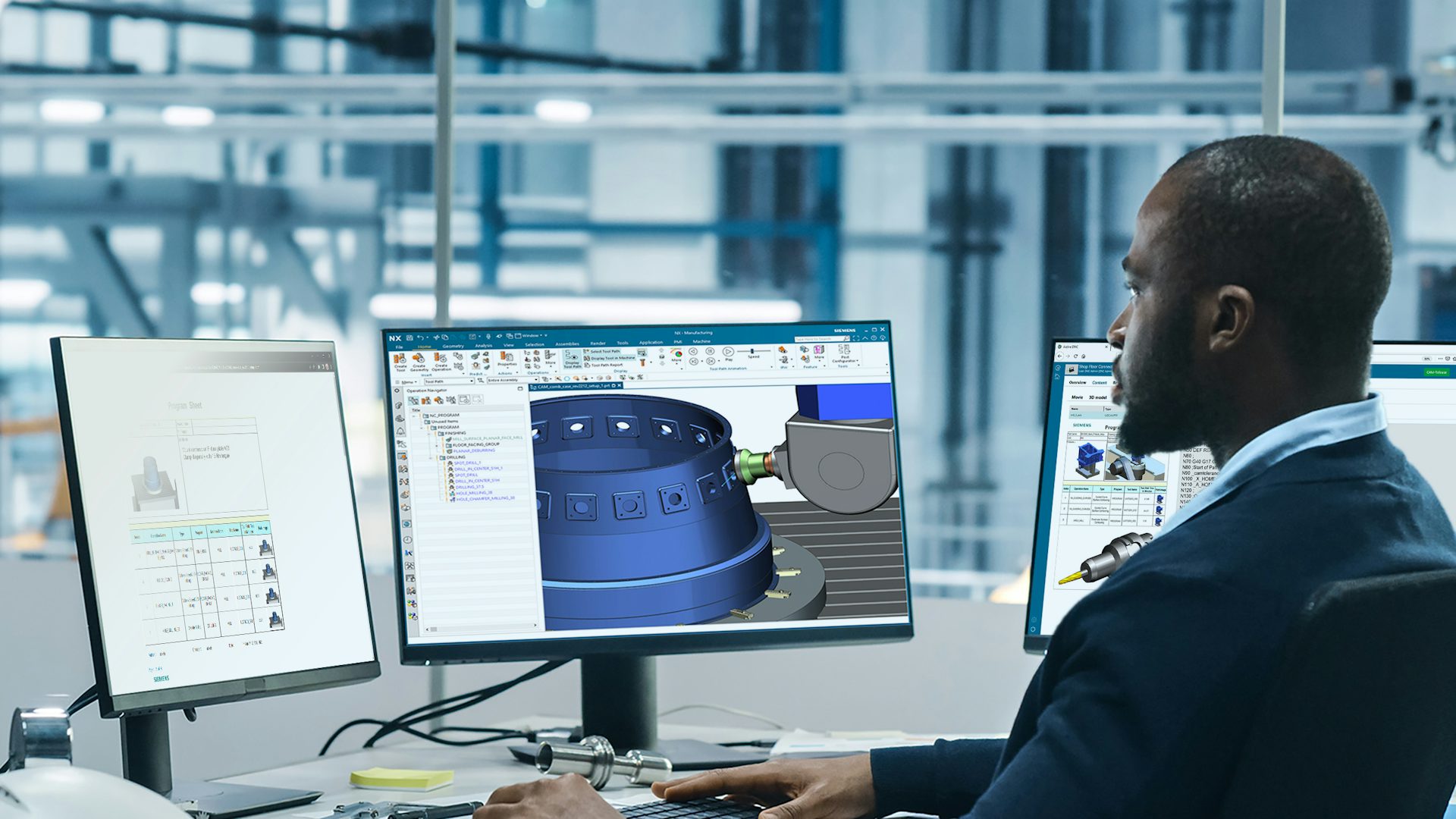

Mettre en œuvre une solution logicielle intégrée pour la fabrication d’outillage et de pièces. Automatisez et connectez de manière transparente la conception, la production et les opérations dans l’atelier d’usinage numérique à l’aide d’une suite d’outils et de solutions logicielles éprouvés et puissants.