Quelles stratégies les ingénieurs aérospatiaux peuvent-ils employer pour accélérer les délais de conception, atteindre les objectifs de performance et assurer une mise en service en douceur ?

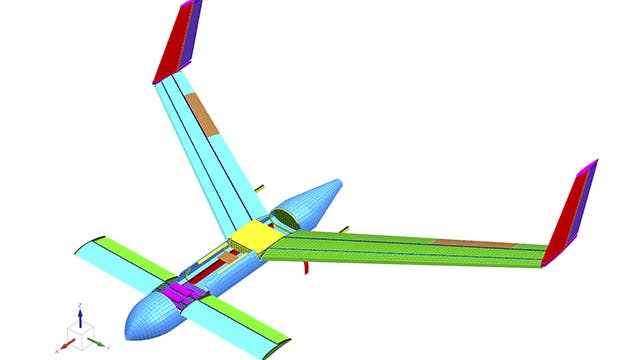

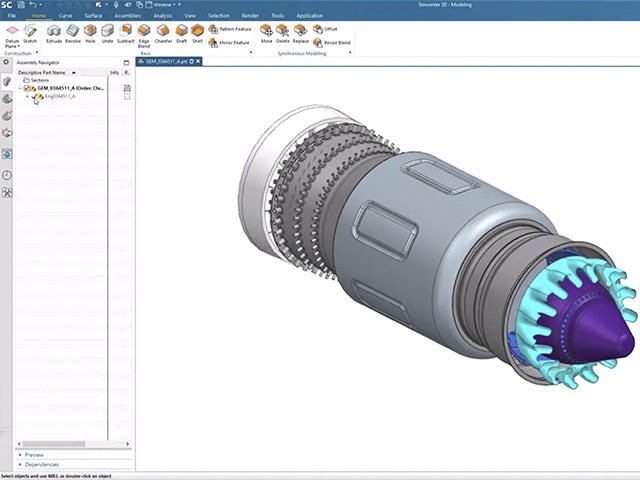

Mettez en œuvre une stratégie intégrée de simulation et de test et utilisez un logiciel de simulation aérospatiale pour stimuler la transformation numérique, éliminer les silos entre les disciplines et obtenir des informations plus précoces sur les performances des produits pour les structures, l’aérodynamique, l’intégration virtuelle et au-delà.