Understanding thermal performance and thermal reliability influences on semiconductor devices and IC packages is important during product development and across the electronics supply chain. Accurate semiconductor device and ic package thermal metrics and testing are vital across the supply chain from semiconductor OEM and packaging houses, through to electronics hardware companies integrating electronics components during product development.

Please watch this webinar on thermal characterization using thermal transient measurement technology. You will learn how this supports determination of thermal metrics, thermal simulation model validation and calibration, through to thermal reliability lifetime prediction studies and manufacturing quality assessment.

Junction temperature (Tj) measurement, electrical test methods and JEDEC standards

Accurate, repeatable junction temperature measurement is crucial for thermal transient test methods. This webinar explains how measurement of junction temperature (Tj) is performed using electrical test methods whereby junction temperature is measured using the device itself as a temperature sensor. You will learn how to determine a temperature sensitive parameter (TSP), such as forward voltage of a diode, and use the TSP to accurately measure junction temperature variation. By applying a power step to a device to induce a thermal transient response (heating or cooling response), and measuring junction temperature, thermal transient data is captured to very high accuracy.

This webinar looks in detail at electrical test methods, standards including JEDEC JESD 51- series and JEDEC JESD 51-14 dual interface method, advantages of dynamic vs static measurement, through to the generation of structure functions (thermal-resistance vs thermal capacitance profiles) derived from thermal transient measurement.

Thermal resistance vs thermal capacitance profiles - Understanding Structure Functions and heat flow path analysis

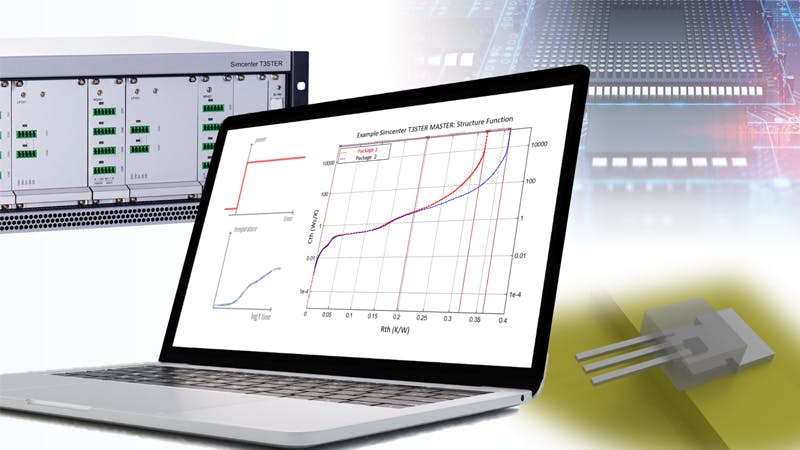

Structure Functions are a thermal resistance (Rth) versus thermal capacitance (Cth) profile of the heat flow path from junction to ambient. They are derived from precise transient junction temperature measurement of package thermal response to an applied power step.

In this webinar, learn how Structure Functions provide detailed insight into thermal information on each layer in a semiconductor package. Explore how engineers can identify physical characteristics of layers including die-attach, base, thermal interface material, package case, and even characterize cooling device performance such as heatsinks, fans, and cold plates.

Thermal Characterization - 4 key uses of structure functions

Structure functions, generated from thermal transient measurement, provide detailed insight into thermal structure and layers of a semiconductor device, package or module so they contain useful information beyond what can be determined from only looking at a single thermal resistance values, or only temperature vs time plots. 4 primary uses of structure functions are explained in this webinar:

- Determining thermal metrics

e.g. thermal resistance values e.g RthJC - Calibration of detailed package thermal models

e.g. to support accurate transient thermal modeling - Thermal reliability assessment

e.g. to assess thermal degradation in conjunction with power cycling - Quality assessment

e.g. assessing die attach void manufacturing defects

Junction to case thermal resistance ( θjc or RthJC ), thermal impedance and other ic package thermal metrics

Whether you are investigating accurate methods to determine datasheet values as a semiconductor device product manager, or as an electronics thermal design engineer, trying to locate sufficient thermal data for selection and simulation model creation, through to verifying insitu thermal properties of an IC package and heatsink integrated in your design – then thermal transient testing can help.

Measurement based structure functions provide the opportunity to determine junction to case thermal resistance (θjc or RthJC), junction to ambient thermal resistance ( θja or RthJA ), and other values as they contain details of the entire heat flow path from junction to ambient. For example, you can verify changes in total package thermal resistance with different TIM materials. You can also determine thermal impedance (Zth) data and other metrics from the accurately captured transient thermal measurement.

Structure functions also support you in calibrating a detailed package thermal model for accurate transient simulation as you can automatically calibrate a simulation based structure function to Simcenter T3STER measurement generated structure function. Such 3D calibrated thermal models are extremely accurate for transient analysis and can be used as a basis to generate fast solving reduced order thermal models for use in circuit simulation as well.

Thermal transient test technology - supporting simulation, reliability testing, quality assessment and much more

There are many applications of thermal transient tester technology beside fundamental semiconductor package thermal characterization. At this webinar, a short summary will be provided on extended applications such as:

- Thermal Interface Material (TIM) bulk thermal conductivity testing

- Power semiconductor thermal reliability testing

- LED lighting thermal and optical testing

- Quality testing: Die attach void assessment, TIM material layer verification, etc.

- Supporting the thermal design supply chain

Thermal Characterization - Presenters and contributors

Simcenter T3STER thermal transient test technology is described in detail during this webinar and the combination of test and simulation through unique linkages to Simcenter portfolio CAE thermal analysis tools. Experienced technical staff contributing to this presentation are detailed below. These staff have a deep understanding of Simcenter thermal test solutions and work closely with leading industry clients in semiconductor, consumer and industrial electronics, automotive, aerospace industries.

- Andras Vass-Varnai – Global Business Development Manager

- Antonio Caruso – Technical Business Development EMEA

- Hon Wong - Technical Business Development Asia-Pacific