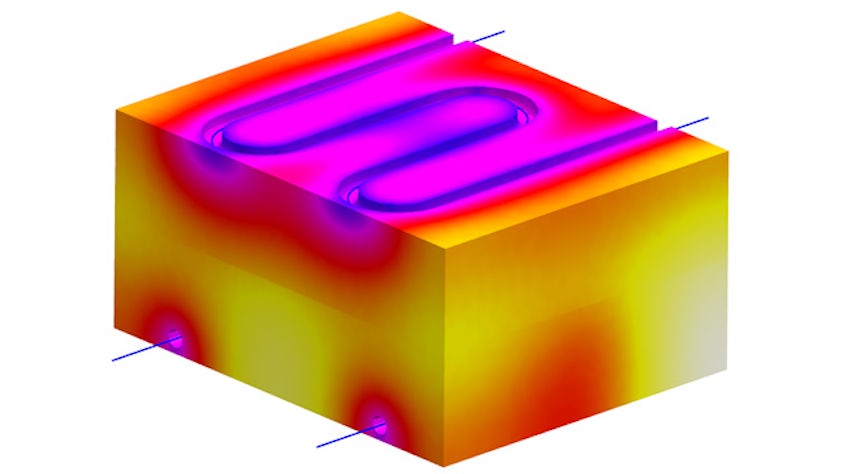

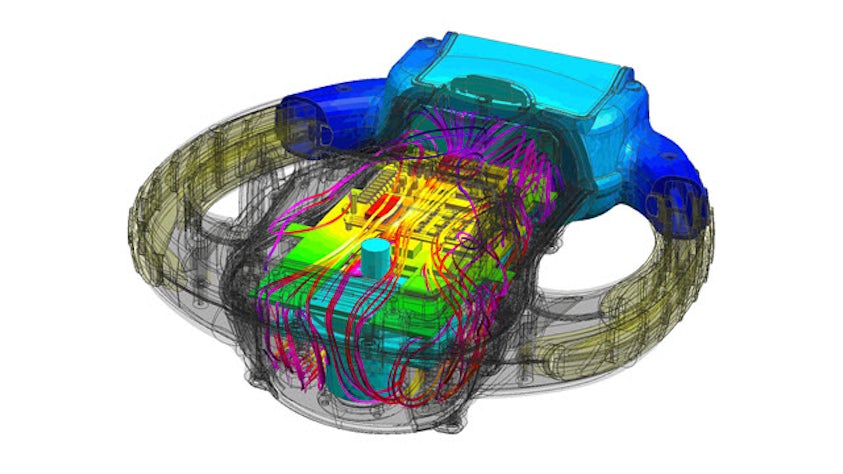

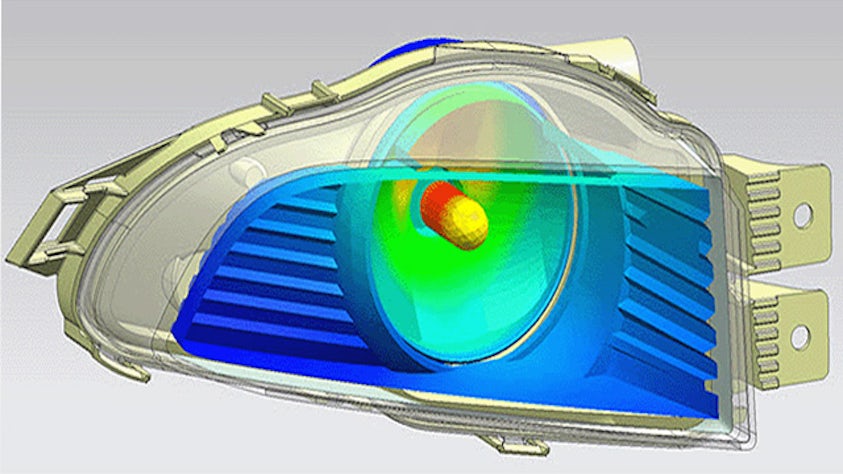

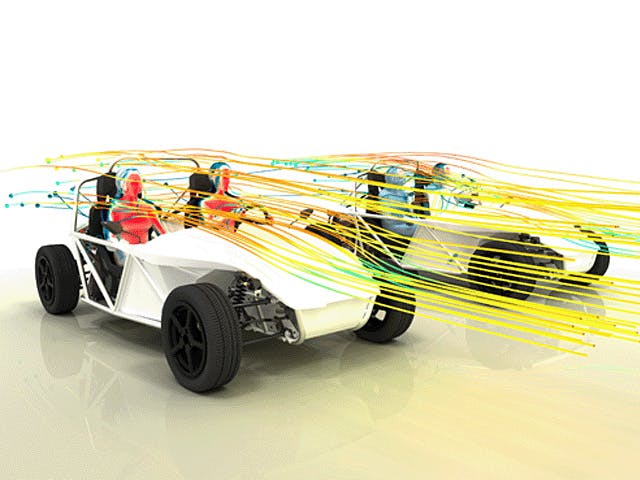

La gestión térmica es un aspecto fundamental que tener en cuenta en una gran variedad de productos, como la maquinaria industrial, los vehículos y la electrónica de consumo. El objetivo de cualquier solución de gestión térmica es mantener la temperatura del producto dentro de un intervalo óptimo para su rendimiento. Sin embargo, conseguirlo puede implicar la adición o la extracción del calor, ya sea de forma activa o pasiva, algo que puede evaluarse mediante un software de simulación térmica.

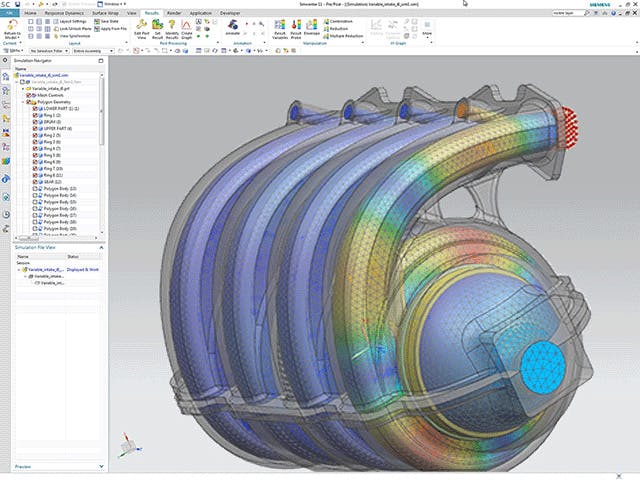

Simcenter incluye funcionalidades de simulación térmica avanzadas que te ayudarán a entender las características térmicas de tu producto y, por consiguiente, adaptar la solución de gestión térmica para obtener un rendimiento óptimo.

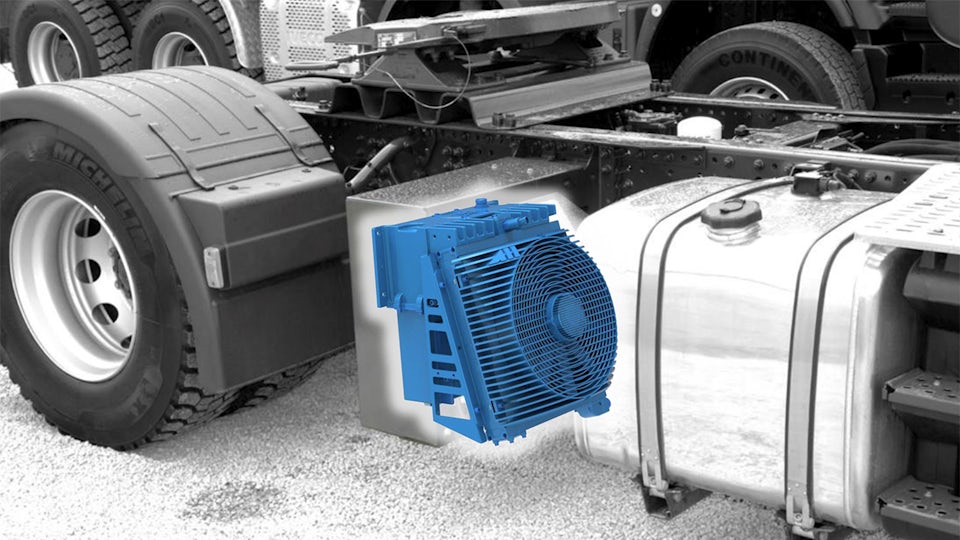

Sobrecalentamiento de equipos pesados en condiciones de funcionamiento difíciles

Durante este webinar, aprende a proteger tus equipos pesados del sobrecalentamiento en condiciones de funcionamiento duras, tareas repetitivas y largas jornadas de trabajo.