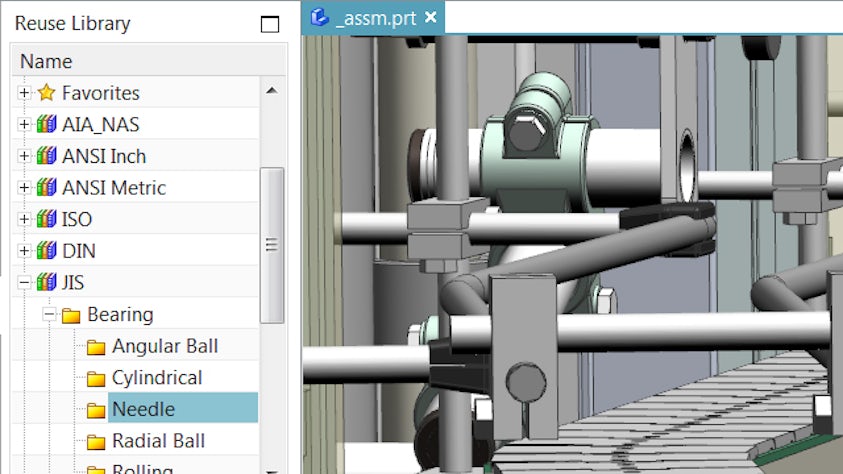

Locate reusable knowledge on an enterprise basis. NX provides an extensive library of knowledge for reuse at your fingertips: reusable designs, standard parts, design features, symbols, 2D sections, profiles, curves, shapes and product templates. You can quickly locate what you need, and drag-and-drop the object into your design.

When using product templates from the Reuse Library, you can automate much more than design modeling. Automate and standardize engineering processes by incorporating product and manufacturing information, drawings, motion analysis, structural simulation and validation checking into templates.

.png?auto=format,compress&w=843&q=60)