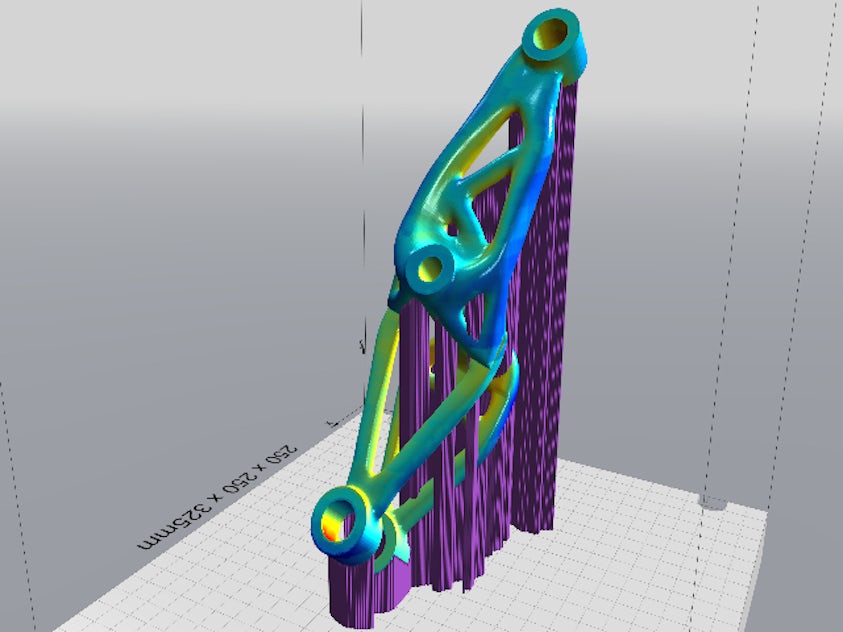

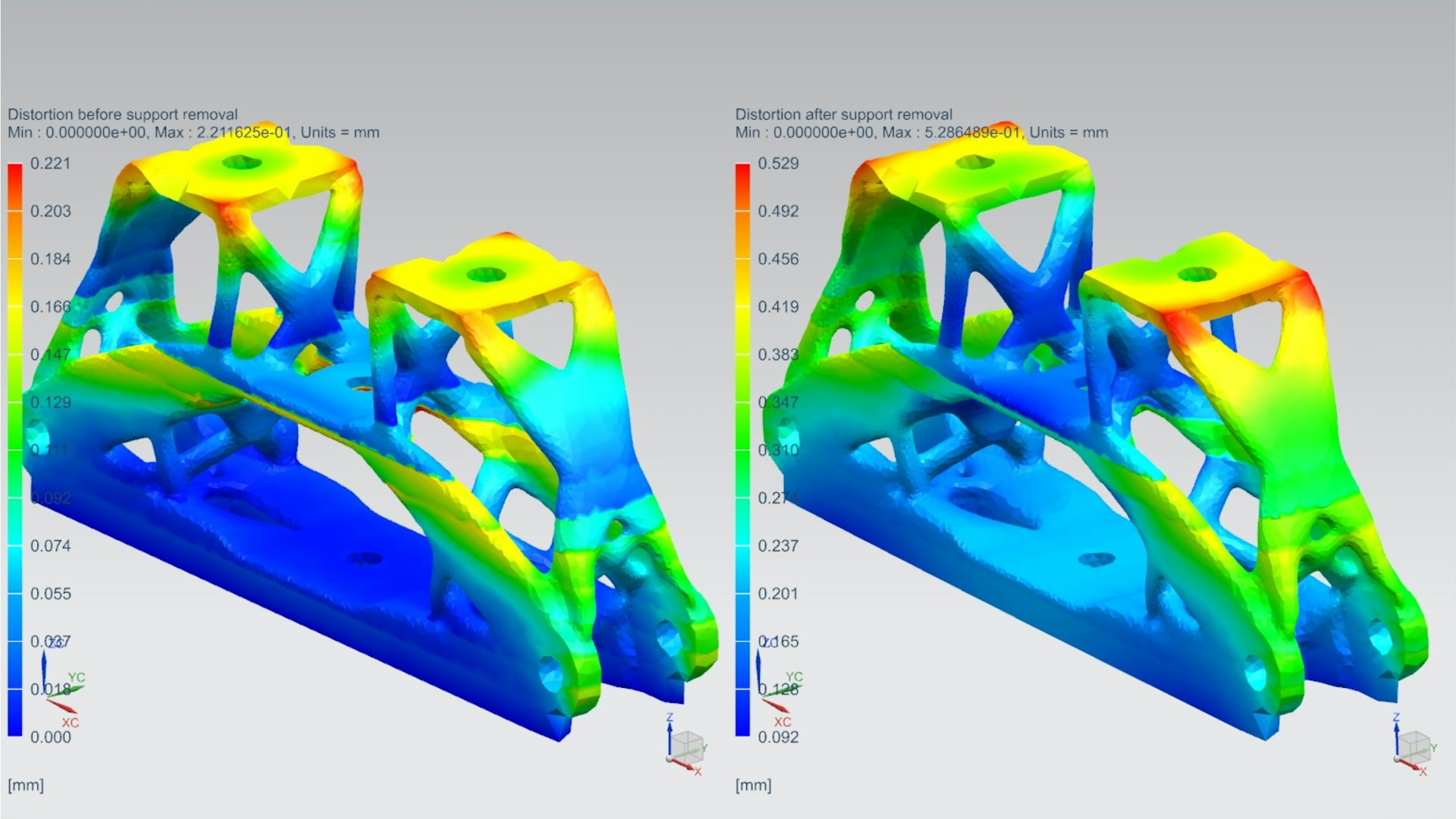

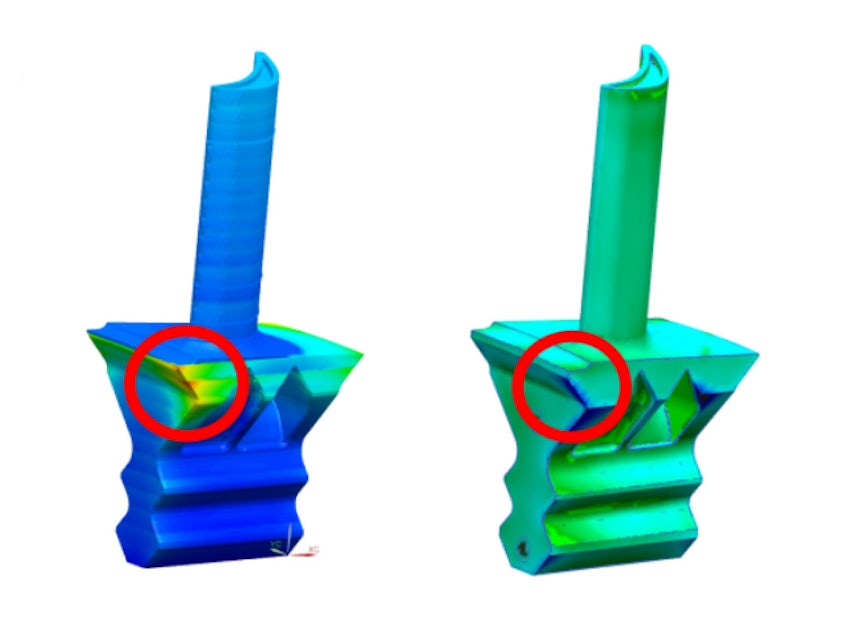

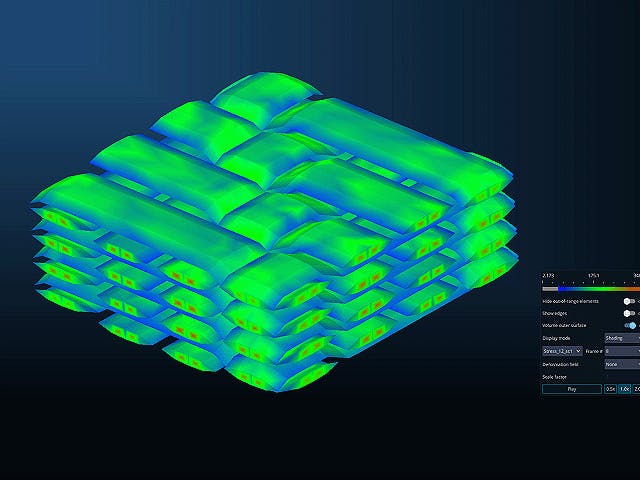

Orientation optimization

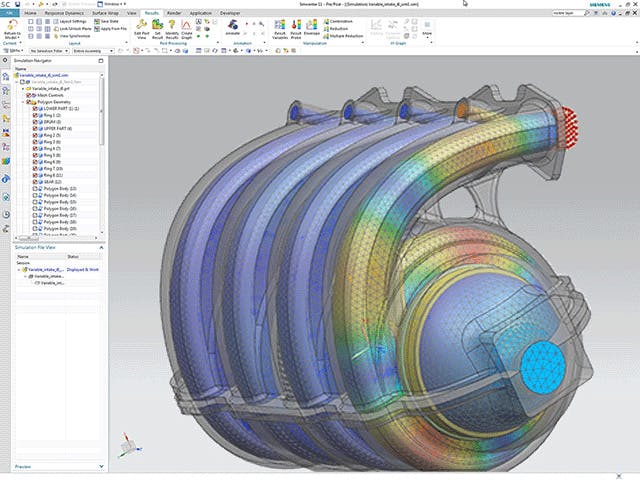

Determine the optimal orientation for parts in the build tray using our additive manufacturing build optimizer solution. It is based on powerful simulation technology that uses a computational approach to simulate multiple part orientations in parallel. Because print quality is dependent on many factors, the orientation of the part in the build tray is important.