Capital

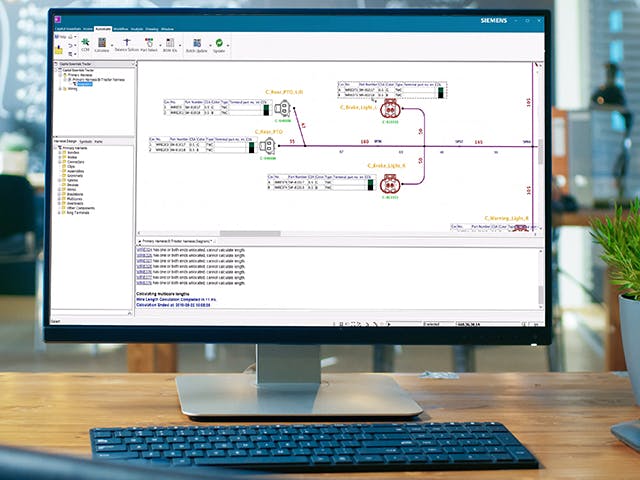

Capital Harness Designer Essentials

Herramienta fundamental de diseño de arneses eléctricos que facilita el desarrollo de diseños detallados de arneses compuestos.

Cambiar país

¿Por qué elegir Capital Harness Designer Essentials?

El software Capital Harness Designer Essentials ofrece un entorno gráfico para generar planos de arneses y tablas de formas. Su intuitiva interfaz de usuario facilita la creación del diseño de arneses.

Acelera el diseño de arneses y elimina los retrasos que se producen en los procesos de diseño tradicionales

Implementa rápidamente para cumplir tus objetivos

Utilízalo de forma individual o bien impleméntalo con Capital Wiring Designer Essentials. Esto permite que los datos de diseño de cableado fluyan entre los diseños de arneses asociados, con el objetivo de reducir esfuerzos y minimizar errores. Valida diseños usando un comportamiento eléctrico integrado y la automatización del diseño con selección de piezas.

Diseña con confianza

Integra el cableado, los arneses eléctricos y los diseños mecánicos asistidos por ordenador para fomentar la reutilización, la coherencia de los datos y la colaboración entre dominios. Automatiza la generación de conectores, cables y empalmes. Calcula las longitudes de los cables, e incluye los valores de los terminales y conectores añadidos/desajustados. Integra el diseño de cableado y arneses para importar cables, conectores y empalmes. Anota las longitudes de los cables. Utiliza bibliotecas inteligentes integradas para componentes y símbolos.

Automatiza los informes

Genera automáticamente informes de fabricación de arneses, incluidas listas de materiales (BOMs) y de corte.

Supervisa las métricas para la corrección temprana

Utiliza el análisis para detectar problemas en las primeras etapas del proceso de diseño, cuando son menos costosos de resolver y se invierte menos tiempo.

Automatiza las tareas

Rellena automáticamente las tablas de conectores a medida que se añaden cables, se seleccionan los terminales y se generan las tablas de cables.

Acelera el proceso de diseño de arneses

Implementa un potente selector de piezas automatizado que configura y selecciona automáticamente terminales, sellos y cables para cada conector, incluidas las asignaciones para complementos y desconexiones. Esto elimina una fuente importante de problemas que se encuentran en el proceso de diseño tradicional.

Genera documentación rápidamente

Una vez que el arnés está completo, se pueden emplear las potentes funcionalidades de generación de informes para crear la documentación necesaria para la fabricación. Los informes se generan automáticamente a partir del plano de diseño, lo que asegura información rápida y precisa. Esto puede reducir significativamente los plazos de producción y evitar errores de fabricación.

Utiliza opciones de diseño de tablas de formas flexibles

Rápida disposición gráfica, ingeniería de arneses y diseños de tablas de formas. Diseña arneses sin escala o a tamaño real con las funcionalidades de disposición de tablas de formas.

Mejora los ingresos

Implementa fácilmente la herramienta en procesos y entornos existentes. Por lo general, el retorno de la inversión se logra en menos de 12 meses.

Escala fácilmente cuando sea necesario

Aprovecha la suite de Capital Essentials, diseñada para una implementación rápida y una instalación sencilla, y consigue un ROI espectacular utilizando una potente funcionalidad. Utiliza las herramientas de diseño y arnés individualmente o impleméntalas juntas. Permite que los datos de diseño de cableado fluyan entre los diseños de arneses asociados, con el objetivo de reducir esfuerzos y minimizar errores. Si es necesario, los usuarios pueden aplicar sin problemas actualizaciones a la suite completa de software Capital.