Using Simcenter Multimech to narrow the potential number of fiber–matrix combinations by 90 percent

Siemens Digital Industries Software solution increases DLR’s productivity and reduces physical testing needs

The German Aerospace Center (DLR)

The German Aerospace Center (DLR) is the national aeronautics and space research center of the Federal Republic of Germany. Its extensive research and development work in aeronautics, space, energy, transport, security, and digitalization is integrated into national and international cooperative ventures. DLR is also responsible for planning and implementing Germany’s space activities.

http://www.dlr.de/en- Headquarters:

- Stuttgart, Germany

- Products:

- Simcenter Products, Multimech

- Industry Sector:

- Aerospace & defense

There is no software available in the market that is as easy to use as Simcenter Multimech and can handle such complex multiscale problems.

DLR

CMCs improve space applications

The German Aerospace Center (DLR) is the national aeronautics and space research center of the Federal Republic of Germany. Its extensive research and development (R&D) work in aeronautics, space, energy, transportation, digitalization, and security is integrated into national and international cooperative ventures. In addition to its own research, as Germany’s space agency, DLR has been given responsibility by the federal government for planning and implementing the German space program. DLR is also the umbrella organization for one of Germany’s largest project management agencies. At the Institute of Structures and Design in Stuttgart, DLR researchers investigate, among other things, the development of ceramic matrix composites (CMC) components for high-temperature and demanding-environment applications.

Composites are increasingly being used in various industries due to their increased strength, lighter weight, and higher resistance to corrosion compared to metals. CMCs have become especially popular in space applications because they can be used in high temperatures.

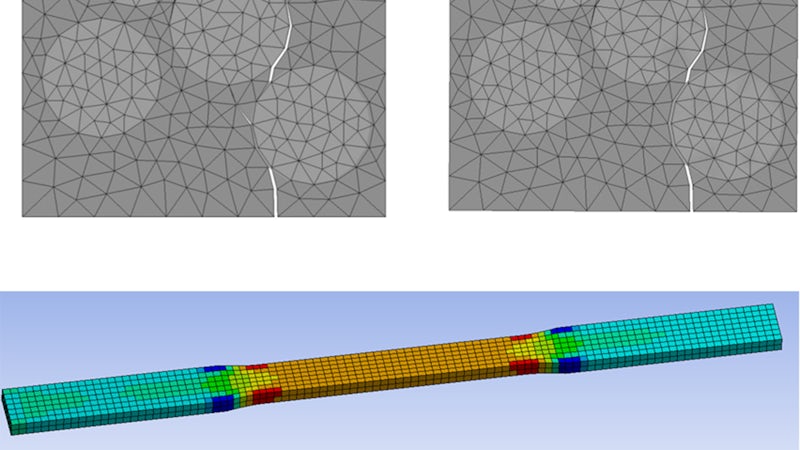

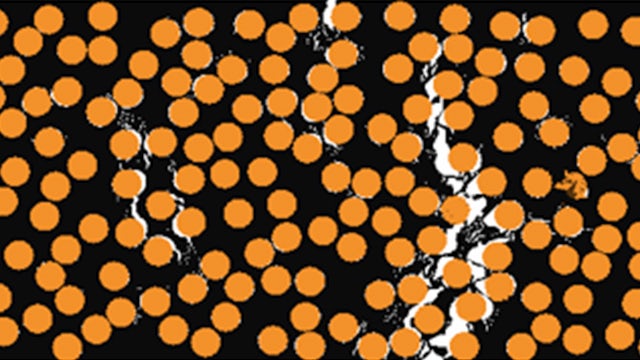

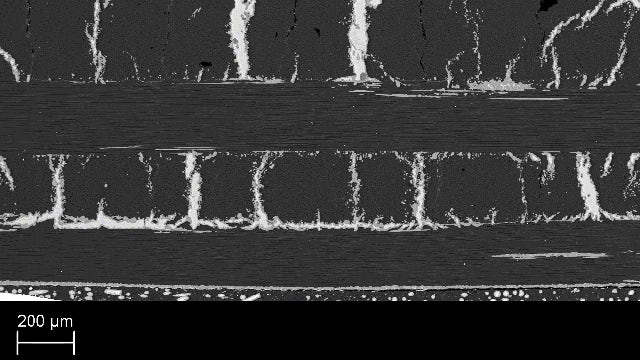

The simulation group at DLR’s Institute of Structure and Design recently began modeling the process of pyrolysis, an intermediate step in the production of CMCs. During pyrolysis, carbon fiber reinforced polymers (CFRPs) are heated to temperatures up to 1,600 degrees Celsius and then cooled down. The team was looking to understand how temperature change would affect the material’s microstructure, especially microcracking, and consequently the material’s behavior, which would affect the performance of the overall part. This analysis is crucial for future CMC components produced by DLR, including nozzles for rockets and turbine shrouds for aero engines, among other applications.

Composites present unique challenges

Despite the advantages of using composites, they also present unique challenges. Composites can behave differently depending on the constituents and manufacturing process. Additionally, failure at the microstructural level can impact the performance of the overall part. Damage at the microstructure, such as cracking, initially affects the overall stiffness but eventually can propagate and potentially cause the entire part to fail.

The team at DLR needed to understand where and how pyrolysis could cause early cracking at the material microstructure during manufacturing. They also had 30 possible fiber and matrix combinations that needed to be explored, and it is immensely expensive to physically test each potential combination.

DLR explored several simulation platforms to help them reduce the time and cost to test their 30 potential combinations. No tools that the team looked into could be used to perform multiscale simulations to the required levels of detail and accuracy, nor did they contain the material and damage models, such as cracking, that DLR was looking for.

Modeling microstructural cracking

In 2018, the team began using Simcenter™ Multimech™ software, which is part of the Siemens Xcelerator business platform of software, hardware and services, to explore the effects of pyrolysis on CMCs.

“Simcenter Multimech allows us to model microstructural cracks and determine how they would affect the overall part,” states Neraj Jain, group leader in simulation and engineering at the DLR Department of Ceramic Composites and Structures. “Using this tool, we can actually see where a crack is developing, how the crack will change our material, and how it will affect the final microstructure of the material.”

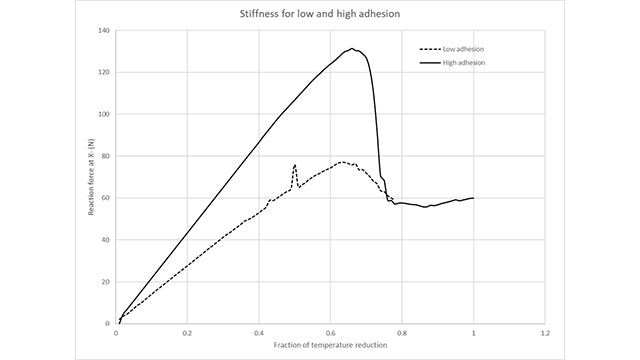

Using Simcenter Multimech, engineers can vary the interface strength between fiber and ceramic matrix – a parameter that is possible to control via manufacturing treatments/conditions – and evaluate how this parameter would influence crack initiation and propagation. This insight enables them to optimize the material and tailor it according to microstructural mechanics, a crucial step to more accurately understand how a part will behave as a whole.

Finally, Simcenter Multimech comes prepackaged with advanced damage and material models not available in other commercial solutions. Using other solutions, the team would have needed to create these models themselves.

Increasing productivity with simulation

The team at DLR has realized numerous time and cost savings using Simcenter Multimech. “For a final part, we have 30 possibilities of fiber and matrix combinations that we have to test individually in order to visualize cracking,” says Jain. “Using Simcenter Multimech, we can narrow down the number of combinations we need to physically prototype to just three or four, a reduction of 90 percent. This can save us 30 percent in testing time and cost, as we no longer need to physically prototype all 30 potential combinations.”

The inclusion of unique material and damage models in Simcenter Multimech, such as cracking, has enabled the team to anticipate they will be able to reduce the time it takes to run simulations by 30 percent since they do not need to create these material models manually.

“Before Simcenter Multimech, we considered developing our own code to perform these analyses,” says Jain. “That process would have taken us at least two years. The Simcenter team is extremely responsive to our needs and develops new features based on our requests, saving us years of development work.

“The efficient integration of Simcenter Multimech with our other FEA tools increases our productivity and brings us closer to our aim of optimizing CMC materials virtually. There is no software available in the market that is as easy to use as Simcenter Multimech and can handle such complex multiscale problems. The way we are able to conduct crack modeling and multiscale simulation will provide lots of opportunities in many projects to come.”

Using Simcenter Multimech, we can narrow down the number of combinations we need to physically prototype to just three or four, a reduction of 90 percent. This can save us 30 percent in testing time and cost, as we no longer need to physically prototype all 30 potential combinations.

DLR