Precision tooling maker improves mold quality, increases competitive strength

Godrej Tooling uses NX to meet stringent customer requirements

Godrej Tooling

Godrej Tooling, a division

of Godrej & Boyce Mfg. Co.

Ltd., manufactures custom-

built, high-quality tooling

for a wide cross-section of

companies in the automobile

sector. It is highly experienced in pressure die

castings, thermo-compression

molds and complex, large

sheet metal tooling.

- Headquarters:

- Mumbai, India

- Products:

- NX

- Industry Sector:

- Automotive & transportation, Industrial machinery

Now, we can make complex component models usable for tooling without losing valuable time to data restoration.

Godrej

Advanced CAD tools provided by Siemens Digital Industries Software

To remain competitive in the tooling industry, a company must produce precise, quality parts and equipment. Godrej Tooling, a division of Godrej and Boyce, has been doing just that since 1935. The company’s ability to deliver on its promise of “tooling our customers’ competitiveness” is borne out in its ISO 9001, ISO 14001 and OHSAS 18001 certifications, as well as work for major automakers including Honda, Toyota, Suzuki, Mahindra & Mahindra, Tata Motors, Caparo and Valeo.

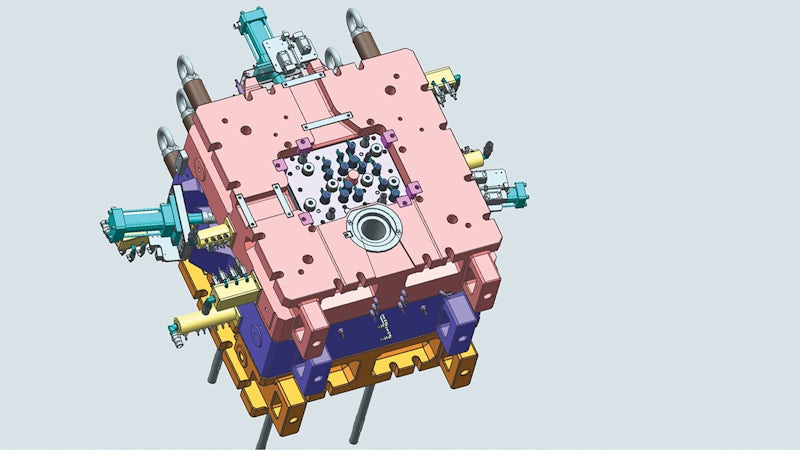

A major factor in Godrej Tooling’s success is its use of the most advanced manufacturing technology. In fact, Godrej Tooling has significant experience with a number of computer-aided design (CAD) systems. However, NX™ software from Siemens Digital Industries Software is Godrej Tooling’s preferred choice for mold design.

“Juggling multiple systems can be a daunting task, but Godrej Tooling takes it in stride, typically importing 3D component files from our customers in the STEP/IGES format,” says Jayesh M Rathod, senior general manager and head of engineering die-casting at Godrej Tooling. “When component models are imported to NX for tool design creation, the process runs smoothly and efficiently. This constrasts with data loss, errors and other problems we too often experience using other CAD systems.”

Streamlining data handling

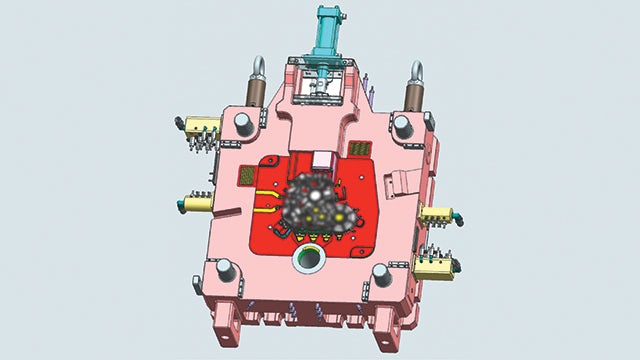

“NX has effective tools to facilitate data handling, such as its ‘examine geometry’ and ‘heal geometry’ functions,” notes Rathod. “NX helps our engineers quickly and effectively repair the 3D input we receive from customers; it gives us a real edge in this area. Now, we can make complex component models usable for tooling without losing valuable time to data restoration.”

In addition, Godrej Tooling utilizes the synchronous technology of NX, which represents a breakthrough step forward in productivity. With synchronous technology, users no longer have to choose between constraint-driven or history-free modeling, no longer have to be a programmer to re-use a model, and no longer need to worry about using data from multiple CAD technologies. Rathod points out, “Using synchronous technology, we can modify the geometry directly, as needed. By eliminating the need to work with data history, we realize big dividends in terms of faster design time.”

20 percent faster turnaround

“NX has helped us significantly reduce die design turnaround because, with synchronous technology, we’ve significantly streamlined the model editing and change management process,” notes Rathod. “Among gains, we’ve calculated that using NX has helped us reduce overall CAD model editing and patching time by 20 percent.”

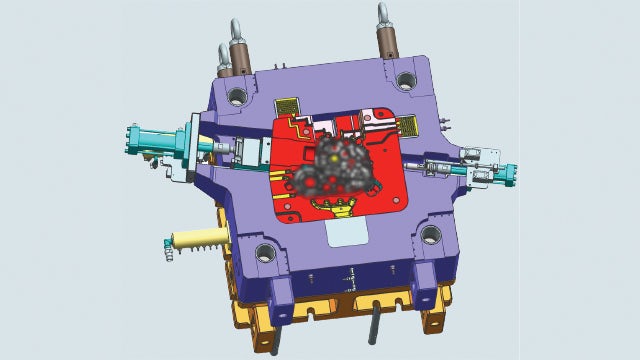

There’s more.

A typical die casting, once manufactured, is subjected to trials. After the trials, components are inspected and changes recommended. Such modifications typically mean adding or reducing thicknesses at certain areas or editing select features. This process is also handled very effectively via synchronous technology. Rathod estimates that 60 percent of errors are rooted in the engineering change management process, with synchronous technology dramatically reducing or eliminating such errors during this cycle.

Overall, Godrej Tooling has gained substantial time and process efficiencies using NX. Moreover, this has resulted in tooling solutions that are continuously improving in terms of time-to-market, quality and innovation. Rathod concludes, “Most importantly, with NX, we’re always enhancing our portfolio and advancing our business objectives. Our competitive position has never been so strong.”

...with NX, we’re always enhancing our portfolio and advancing our business objectives. Our competitive position has never been so strong.

Godrej