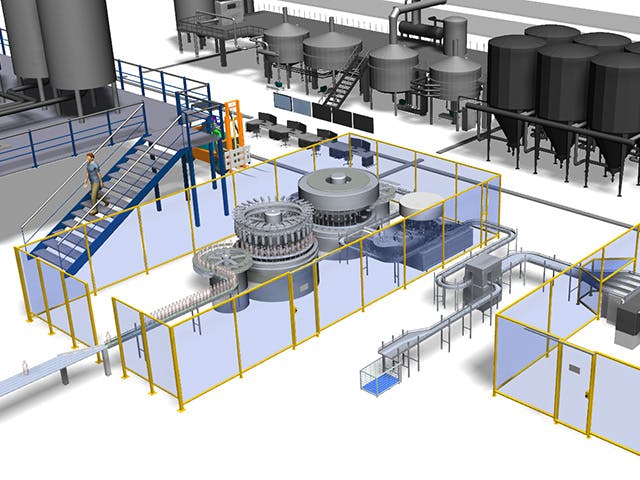

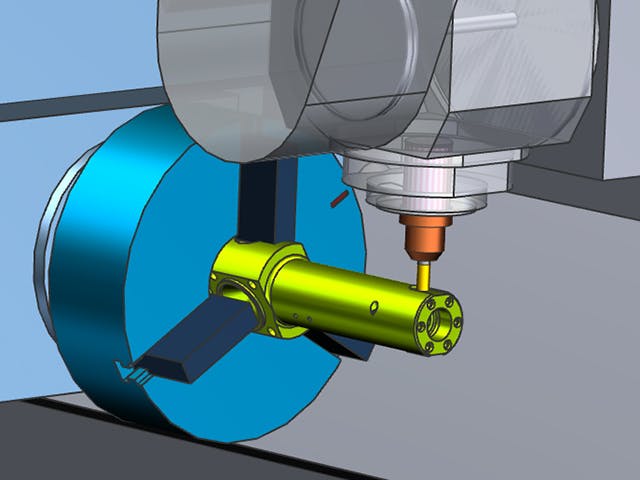

La fabricación digital es el uso de un sistema integrado basado en computadora compuesto por herramientas de simulación, visualización 3D, análisis y colaboración para crear definiciones de productos y procesos de fabricación simultáneamente. La fabricación digital evolucionó a partir de iniciativas de fabricación como el diseño para la capacidad de fabricación (DFM), la fabricación integrada por ordenador (CIM), la fabricación flexible y la fabricación ajustada, que ponen de manifiesto la necesidad de un diseño colaborativo de productos y procesos.

Muchos de los beneficios a largo plazo de la gestión del ciclo de vida del producto (PLM) no se pueden lograr sin una estrategia integral de fabricación digital. La fabricación digital es un punto clave de integración entre el PLM y las aplicaciones y equipos de la planta de producción, lo que permite el intercambio de información relacionada con el producto entre los grupos de diseño y fabricación. Esta alineación permite a las empresas de fabricación alcanzar los objetivos de tiempo de comercialización y volumen, así como obtener ahorros de costos al reducir los costosos cambios posteriores.

Productos relacionados: Tecnomatix | NX | Solid Edge