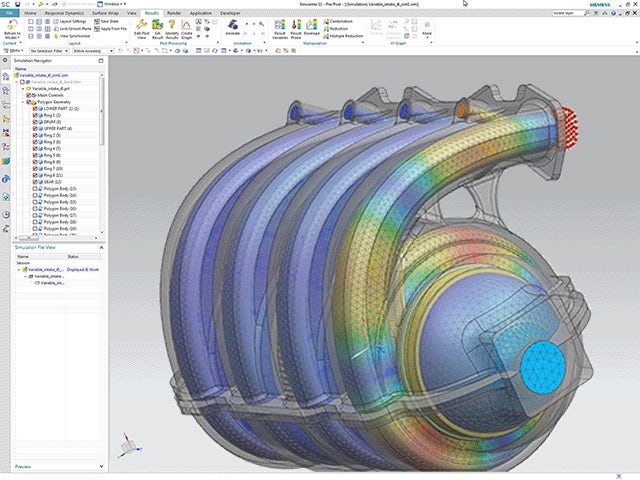

Comprender y ofrecer un rendimiento entre dominios requiere soluciones de simulación y prueba que se puedan implementar en todas las fases de desarrollo y en todos los dominios de rendimiento y física. Además, estas actividades deben estar vinculadas, no llevarse a cabo de forma independiente, para capturar fenómenos multifísicos del mundo real y equilibrar los atributos conflictivos. Simcenter ofrece una cartera integrada de las mejores soluciones predictivas de simulación, prueba y exploración de diseño que abarcan todas las fases del proceso de desarrollo de productos para resolver los problemas más difíciles de la ingeniería y ayudar a transformar la ingeniería impulsando la productividad y potenciando la innovación.

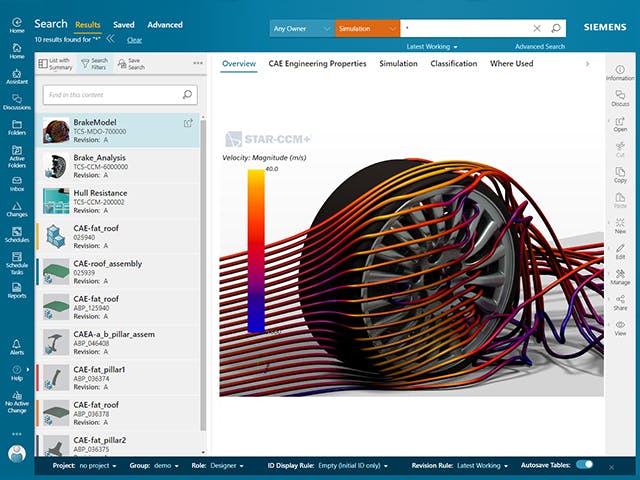

La simulación y las pruebas ya no pueden verse como actividades aisladas. El gemelo digital aporta valor a lo largo de todo el ciclo de vida y su evolución debe gestionarse para la trazabilidad y el impacto del cambio. Esto solo es posible mediante la realización de simulaciones y pruebas como parte de una iniciativa general de desarrollo de productos digitales. Siemens Xcelerator difumina los límites entre los dominios de ingeniería, como la eléctrica, mecánica y de software, y las soluciones de simulación y prueba de Simcenter complementan las soluciones de Siemens Xcelerator en las fases de diseño, realización y optimización del ciclo de vida.

En el camino hacia la transformación digital, las empresas necesitan socios confiables con los recursos para impulsar continuamente la innovación en las herramientas y aplicaciones. Siemens gasta significativamente en investigación y desarrollo, aprovecha las asociaciones con empresas establecidas en áreas adyacentes e invierte en nuevas empresas que tienen las tecnologías que podrían transformar los negocios en el futuro. Todo esto garantiza un flujo constante de innovaciones que pueden ayudar a nuestros clientes a mantenerse en el edge de corte y obtener los beneficios de la digitalización más rápido que sus competidores. Los servicios de ingeniería y consultoría de Simcenter proporcionan un profundo conocimiento del sector, instalaciones, recursos y experiencia para acelerar la transformación de los procesos de ingeniería y el retorno de la inversión resultante.