Static and dynamic analysis of rotors and rotating machines is paramount to avoid unnecessary vibration and ensure the reliability of the machines. How does your shaft move in the hydro bearing during startup, shut down and under the loads from an operating cycle?

An efficient measurement and analysis technique can provide insight into the source of the unbalance, origin of static, dynamic loads and avoid vibration issues.

View this webinar to learn how to measure the dynamic motion of shafts in the bearing using key-phasor and proximity probe.

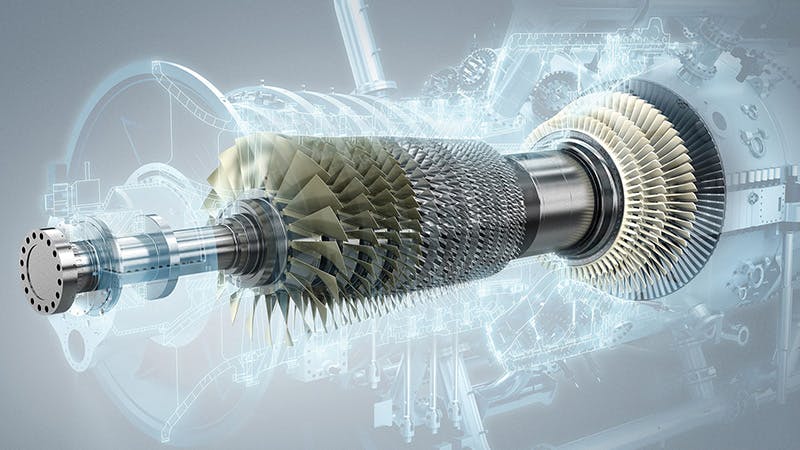

Rotor dynamics measurement

Rotor dynamics measurement techniques involve analyzing the operation of the machine at various speeds and operating loads using probes and keyphasors. A smart combination of several analysis plots, such as orbit, centerline, polar, full-spectrum plot, and operational deflection shape provides a detailed analysis of the rotor unbalance, shaft motion, and the structural behavior of the complete installation. In this webinar you will learn about:

- Rotordynamic measurement, including sensors and setup

- Analysis tools, typical plots and their physical meaning

- Rotordynamic processing and analysis in a leading testing software

Rotor orbit analysis and measurement

The uneven distribution of mass around an axis and the dynamic loads during rotation can cause rubbing resulting in excessive vibration and noise, decreased life of the entire system and maybe even unsafe work conditions. Rotor orbit measurement aims to achieve satisfactory running of the rotating machine in its actual operating environment, which means that the vibrations caused by the dynamic operations are below a pre-defined limit.

View this webinar to get insight into the rotor vibration measurement techniques involving sensors and probes.

Rotor dynamics: Oil whip and whirl

Oil whip and whirl resulting from dynamic operating conditions can lead to unnecessary vibration in rotors.

View this webinar to efficiently identify the cause of oil instabilities using leading measurement tools.

Rotor dynamics: critical speed

Crossing the critical speed will lead to resonance and can lead to very dangerous situations. Using testing software’s full-spectrum plot, color map plot and center line plot features, rotor manufacturers (industrial pumps, turbines, compressor etc.) can gain valuable insight into the critical speed of the rotating parts.