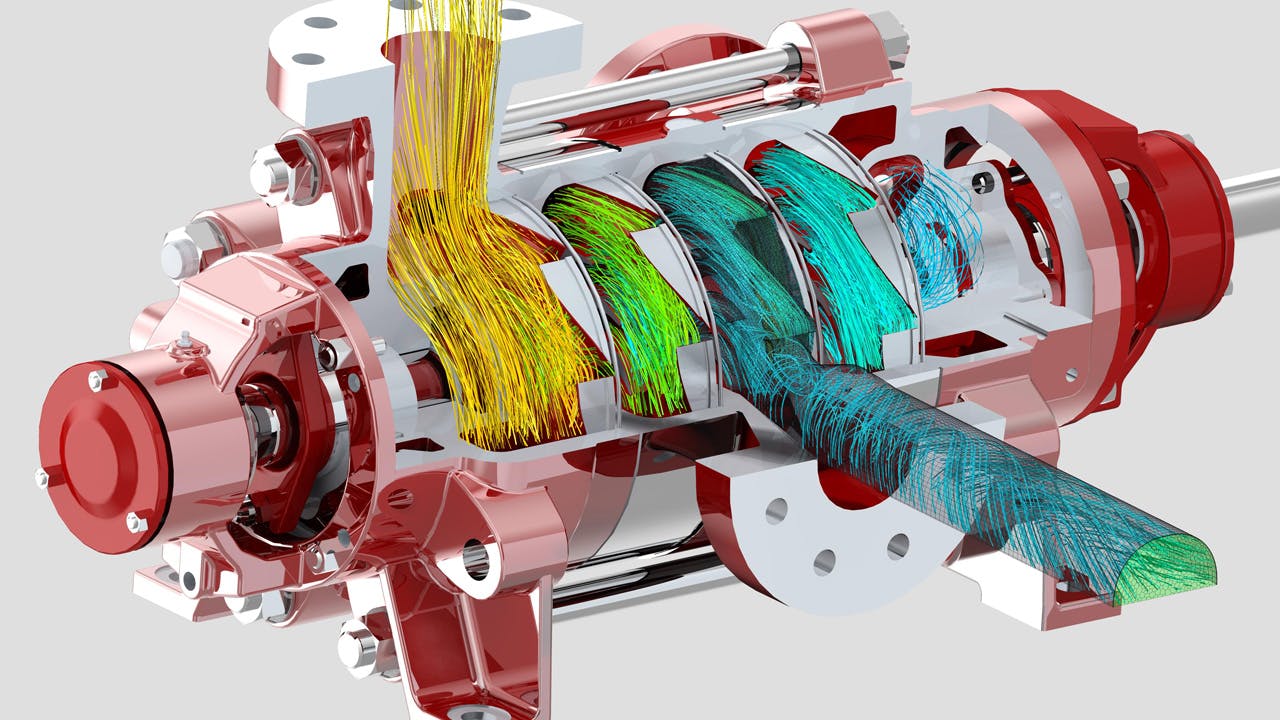

Pumps can be quite complex in terms of both the geometry as well as the underlying transient physics of the fluid happening inside. If you rely primarily on physical tests of prototypes to determine the effectiveness of your designs, then your competition is already winning.

Physical testing is too costly and time consuming for today’s fast-paced market. Instead, you need to know that your products are meeting performance requirements at each step of the development cycle before you ever cut a single prototype. This can be achieved through 3D computational fluid dynamics (CFD) simulation of pump system performance.

In this webinar, you will learn more about how you can use CFD to predict pump performance. In addition, you will also learn about common bottlenecks in the pump simulation process and the technology, license scheme and technical support you can use to get around those bottlenecks.

Read our case study to learn how a heating and cooling equipment manufacturer uses Simcenter STAR-CCM+ to save time and costs by rapidly simulating multiple pump designs.