Over the last few decades, industrial machines have become more and more complex. Whether a machine is engineered for packaging, bottle filling, metal forming, or textile machinery, it is critical for you to ensure your machine achieves an optimal balance between all performance attributes - such as:

- Productivity: maximizing output while reducing the cost of production

- Accuracy: limiting the reject rate

- Reliability: maximizing in-service time

- Efficiency: reducing the cost of energy and complying with local environmental regulations

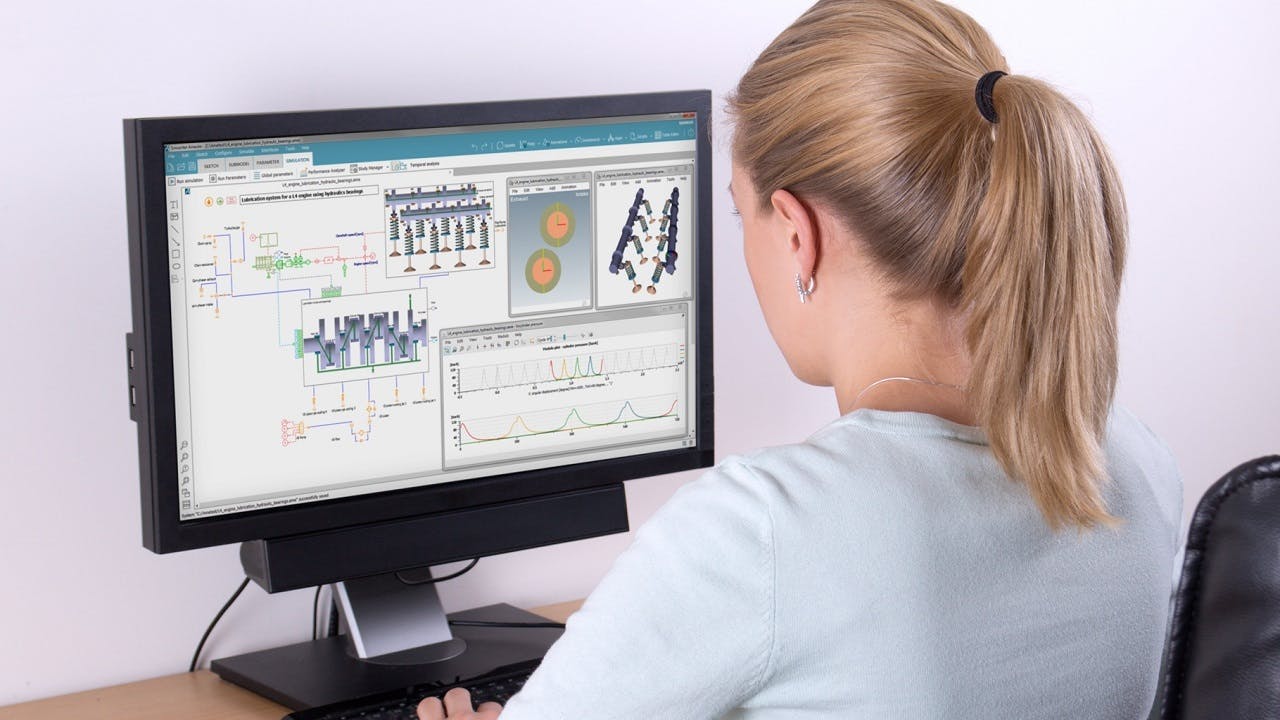

This webinar introduces how system simulation can help you assess machine performance at an early stage of the development cycle to find the best trade-off between all these criteria.

You will also see a live demo showing how Simcenter Amesim can be used in the context of the sizing of the electric drives for delta robots -- which are very popular in picking and packaging in factories thanks to their fast and accurate maneuvers.

This demo will show examples of:

- 3D mechanical simulation starting from CAD data

- Computation of requests for speed and torque to evaluate a specific performance requirement

- Virtual integration of the selected motors, simulation on working profiles to check performance, precision, and energy consumption