Industrial electric motors are the power horse of modern factories and equipment. Developing a robust and efficient electric motor is crucial for the smooth and optimal conversion of electrical energy into a mechanical one; to drive pumps, conveyors, cranes, gearbox, fans, whitegoods etc.

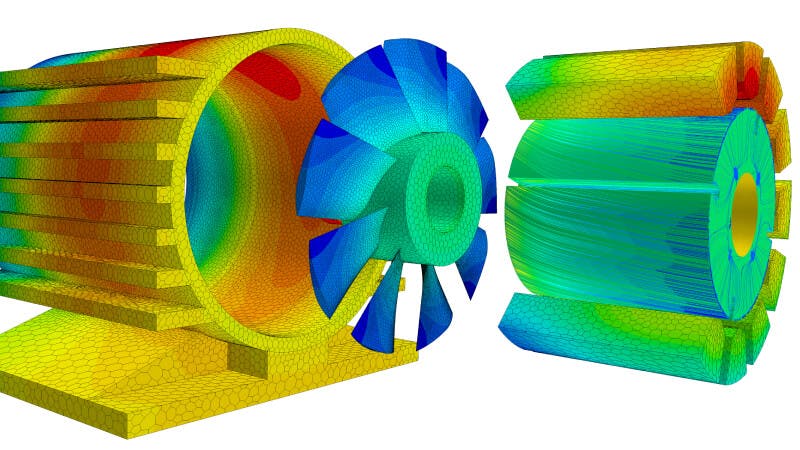

Industrial electric motor components’ (rotor, stator, armature, commutator, windings, bearings, and casings) design choices affect the cost, performance, efficiency, and NVH characteristics. The electric motor should function efficiently over decades withstanding the damaging electromagnetic, mechanical, and thermal stresses.

During product development, motor engineers and designers face several complex challenges as the field of electric motor design and engineering involves a variety of disciplines: mechanics, electromagnetics, electronics, fluid and solid dynamics, heat transfer, control theory and acoustics. To meet customer-specific requirements effectively, motor manufacturing companies rely on multi-disciplinary simulation and testing tools.

In this webinar, we will explore the best practices for designing and optimizing the performance of rotating electric motors. Simulation and testing solutions provide multi-physics libraries to efficiently analyze the electric motor design choices, evaluate real performance when subjected to actual duty-cycle before prototyping.

- Analyze electromagnetic, thermal, NVH, and system-level integration issues of electric motor

- Reduce industrial electric motor prototype costs and design times through a multi-disciplinary approach covering concept design to control validation

- Perform sensitivity and multi-objective optimization of models to meet all the performance requirements.

Electric motor design and analysis

Multiphysics electric motor design and analysis helps to gain insight into motor performance for any complex design before prototyping. In this electric motor design and analysis training we discuss successful engineering methodologies that can significantly enhance the design quality, improve design standards, and accelerate the design process.

Electric machine simulation and testing

Simulation and testing solutions help motor manufacturers address key engineering challenges —optimize machine design for energy efficiency, reduce power losses, avoid overheating, eliminate vibration and acoustic noise.

Advances in electric motor simulation

Electric motor design is a multi-disciplinary domain that is iterative and increasingly collaborative. Being aware of the latest advancement in the simulation of electric motors can help develop a new perspective on an existing design process. Register to this webinar and have a clear understanding of the advanced technology that leading motor engineers employ in their electrical machine design project.