Heatsinks are used extensively for electronics thermal management, whether standalone or in combination with other electronic cooling solutions. This ensures critical electronics components operate within junction temperature limits for reliability and to maximize performance.

Attend this webinar to learn about designing an efficient heatsink for heat dissipation. Topics start from heat transfer and fluid flow fundamentals through to useful tips and performance factors to consider in system integration. Concepts will be illustrated with thermal CFD simulation examples. Learn more about the value of evaluating tradeoff designs efficiently with parametric studies and design space exploration so you can achieve your thermal management design goals for thermal performance and minimized cost.

How to design a great heatsink – Key considerations and optimization

Thermal design topics:

- What are the risks of selecting a heatsink only with datasheet values?

- When is a heatsink appropriate?

- What is a thermal budget and how do you use it?

- Minimizing mass and cost

- Optimizing heatsink thermal performance in a system

Whether you are designing a heatsink utilizing natural convection cooling, forced convection fan-cooled heatsinks, sealed enclosure casings as heatsinks, or where heatsinks are incorporated with other electronics cooling solutions, this presentation is relevant to you.

Heatsink thermal resistance, surface area, thermal conductivity and other factors

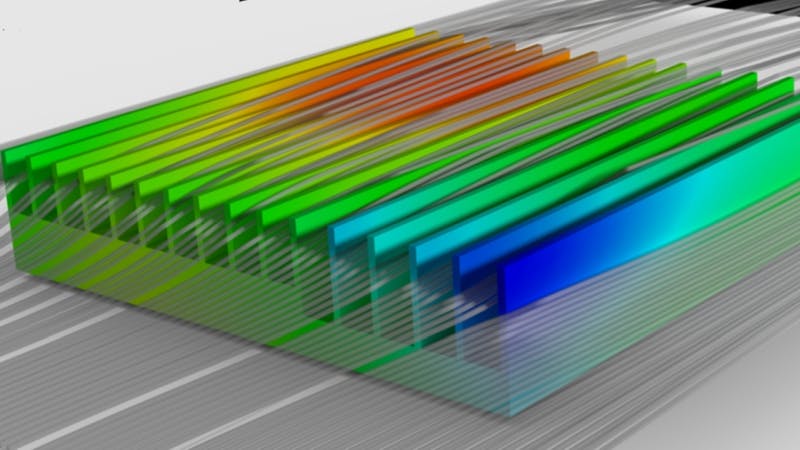

Optimizing a heatsink to dissipate heat efficiently from a device to its ambient surroundings focuses typically on low thermal resistance and maximizing surface area exposed to airflow. This webinar will go into the full range of influences on the performance of a heatsink, so you are equipped to develop or select an efficient heatsink for your design whilst considering cost constraints. Physical factors including:

- Thermal conductivity

- Heatsink topology

- Airflow – Natural convection to forced air convection

- Thermal resistance and how to minimize it

- Thermal interface material considerations

- … and more

Selecting the best heatsink for thermal management in a system

To fully understand performance, heat dissipation to the surroundings via heatsinking must be considered in the system environment and operational conditions. For example, think of cooling a single high power component in a passive manner with natural convection in an enclosure; or multiple heatsinks cooling several components on a detailed PCB with complex airflow in a fan-cooled server; or where a heatsink is integrated with a heat pipe to dissipate heat away from the critical component in small form factor consumer electronics products. Several reasons why you need to consider heatsink performance in a system will be discussed at this webinar using examples.

Electronics thermal management presenters

Technical presenters, each with between 20-35+ years in electronics thermal management experience in design, simulation and consulting, draw on their knowledge and background of extensive published conference papers and educational material to bring you this presentation.

Robin Bornoff, Senior Key Technical Expert

John Parry, Strategic Business Development Manager

John Wilson, Electronics Thermal Management Business Development Manager (Americas)