12 ways to faster wiring and harness design

The growing complexity of electrical design requires an evolution in the design tools used by the electrical engineers of today. Even relatively simple modern products are often more sophisticated than the cutting edge of 25 years ago. To cope with these increasingly complicated designs, engineers need electrical systems engineering software that takes the complexity out of the design task and helps them to work smarter and faster. This paper presents 12 ways the Capital Essentials wiring and harness design solution can help reduce design cycle times, eliminate rework costs, and improve margins.

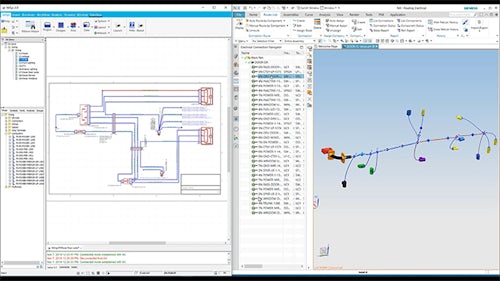

Technology to reduce design-cycle times, reduce rework costs and improve margins

Capital Essentials is used by OEMs and harness manufacturing companies worldwide, from small, 10 employee companies up to the biggest companies in the industry. With automation capabilities that eliminate many of the most labor-intensive and error-prone tasks, these companies reduced design-cycle times, reduced rework costs and improved margins. Some benefits include:

- Advanced analysis and verification allows testing before building, including MCAD integration

- An integrated parts library for no mistakes on part selections

- Wire import from spreadsheets for faster quotation turnaround time and design creation