Air Dynamics Simulation of Oil-Free Air Turbo Compressor

Air dynamics simulation used early and often throughout the design process leads to better air turbo compressors developed at a lower cost.

That’s because predicting the performance of air turbo compressor prototypes is a critical element of the design process.

The sooner predictions are available, the more time design engineers have to optimize the device and account for a number of important factors.

Download this white paper and learn more about frontloading computational fluid dynamics (CFD) software to predict compressor performance.

Analyze air-turbo compressors at all development stages

The traditional approach to CFD simulation for any product, including air-turbo compressors, delays any simulation until the initial design is complete.

Frontloading simulation and integrating a CFD solution within the designer’s native CAD environment accelerates the process and leads to better designs.

With simulation options readily available to design engineers, they can also investigate and test a wide range of designs quickly.

This frontloading approach inserts valuable analysis throughout every stage of the development process, enabling engineers to make bigger innovations more quickly.

Improve industrial air compressor performance with computational fluid dynamics software

Improving highly efficient air-turbo compressors is challenging without proper insights on how decisions impact end-product performance.

Computational fluid dynamics software provides the necessary insight to making improvements to oil-free air turbo compressors and other pieces of equipment.

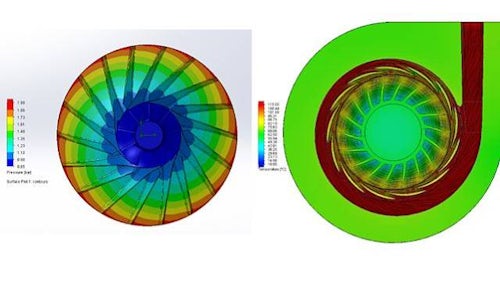

For analysis, the full assembly of the compressor was used, so every geometric feature of the compressor, presence of rotating parts, and special requirements for temperature were accounted for.

Simcenter FLOEFD testimonial: Tamturbo Oy oil-free air turbo compressor

This white paper examines a Simcenter FLOEFD user story in their quest to improve industrial air compressors.

The Simcenter FLOEFD testimonial follows their processes and methodologies to design and build a better oil-free air turbo compressor.

Find out how they used computational fluid dynamics software throughout the development stage to make real-time improvements every step of the way.

Discover how Tamturbo Oy transformed their company’s view of oil-free technology into a worldwide success story.