PCB DFM solutions by Valor

Valor DFM Solutions

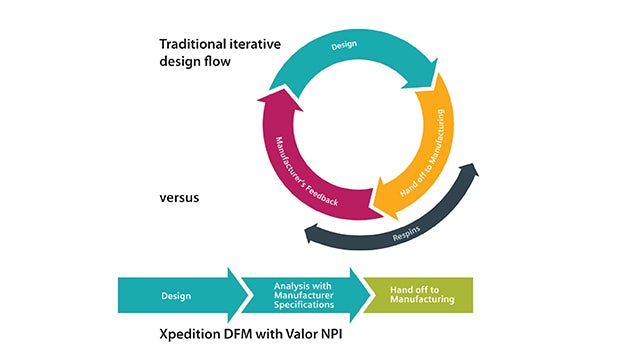

Why is it that two to three respins of PCB designs during new product introduction is "Expected" instead of the "Exception"? High-speed PCB designs have easily overlooked issues that can affect manufacturing. Valor DFM solutions reduce re-spins in a PCB design, getting you to market sooner.

Connect Group: Powered by Valor NPI

Company:Connect Group

Location:Kampenhout, Belgium

Product:Electronic Manufacturing and Technology Services

Size:Medium

Siemens Software:Valor NPI

Tomorrow's Vision:Time is money. That is why the Connect Group brings DFM in at a very early stage in the product lifecycle. Anticipating problems in production and incorporating testing into design help create a win-win system for the Connect Group and their customers.

Valor DFM Products

Valor NPI for Any EDA Flow Trial

This free, online trial will let you learn how moving manufacturing knowledge into the layout process can eliminate potential manufacturing issues early with Valor NPI.

Electronics manufacturer reduces DFM cycle time by 60%

NI (formerly National Instruments) has taken a journey from using all manual processes to instituting some design-for-manufacturing to embracing the benefits of DFM. Their initial use focused on using Valor™ NPI software for final DFM checks before release to manufacturing.

.jpg?auto=format,compress&w=640&h=360&q=60&fit=crop)