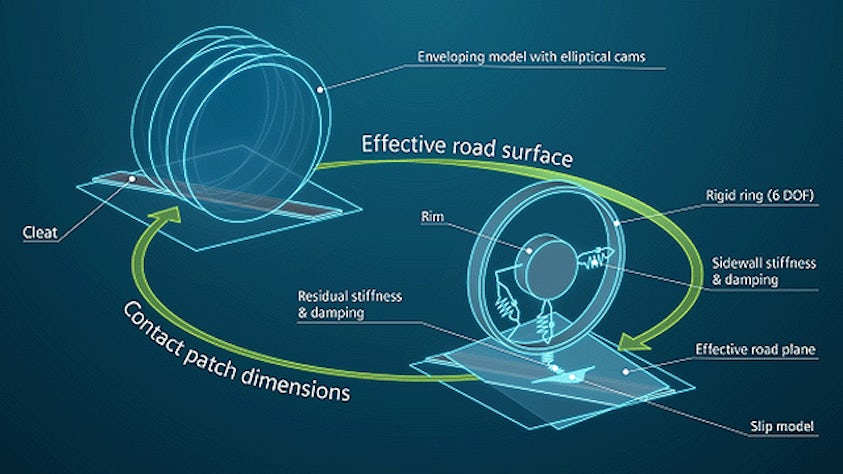

The tire is a complex and highly non-linear vehicle component that has a significant effect on the behavior of a vehicle. As the number of vehicle models on the market continues to increase, so does the number of possible use cases that need to be tested and validated. This fact, in combination with the strive for reduced development times, calls for more simulation instead of physical vehicle testing.

Modeling tire performance requires a lot of expertise and specialization. For this purpose, Simcenter offers engineers scalable and customized solutions. The ultimate goal is for simulation to accurately represent tire forces and moments so they can be propagated to various vehicle performance simulations.

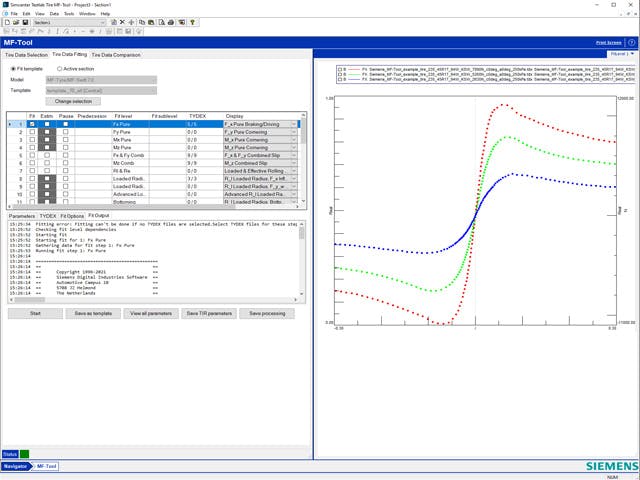

Tire model parameterization

A complete revamp of MF-Tool for user-friendly tire model parameter identification.