Choose Simcenter and benefit from an open, powerful and user-friendly multiphysics system simulation platform to model, run and analyze complex systems and components.

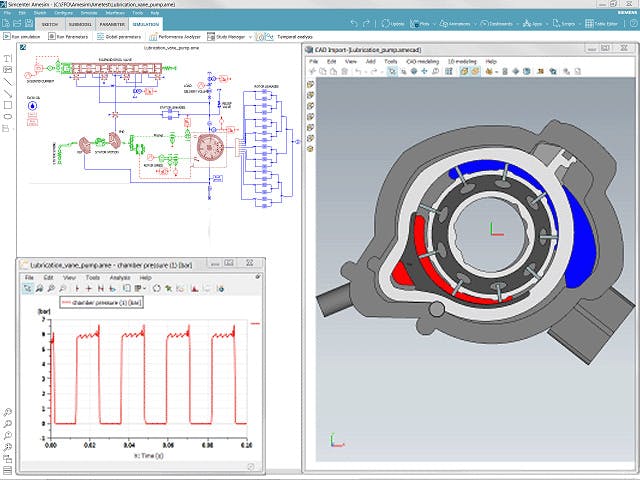

Access powerful analysis

With its powerful facilities, analysis and optimization tools, the solution offers an advanced and easy-to-use environment for 1D multiphysics system simulation and robust design.

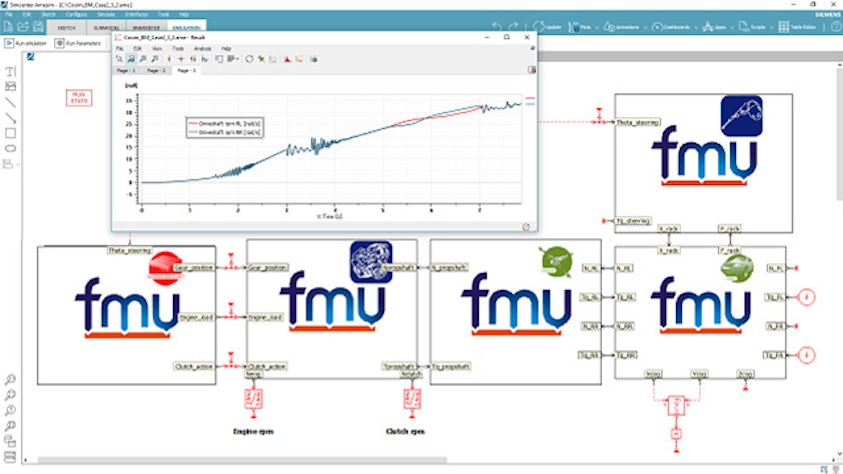

Various scripting and customization capabilities provide seamless integration of Simcenter within your existing design processes. Being open and flexible, the Simcenter platform efficiently interfaces with many 1D and 3D computer-aided engineering (CAE) software solutions.

Enable real-time targets with a capable framework

It helps you quickly derive and export models for standard real-time targets by providing a consistent and continuous model-in-the-loop (MiL), software-in-the-loop (SiL) and hardware-in-the-loop (HiL) capable framework.