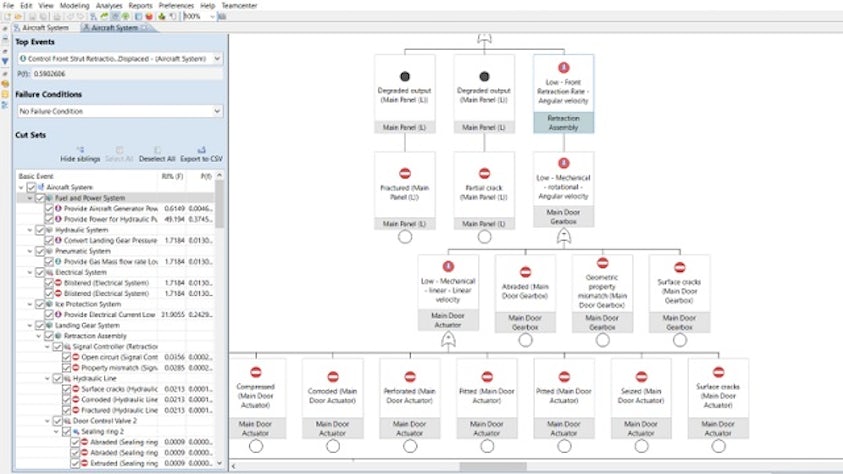

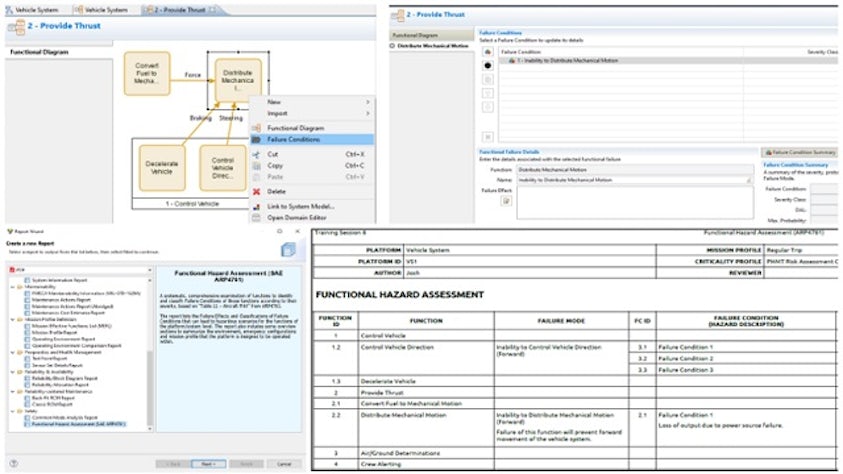

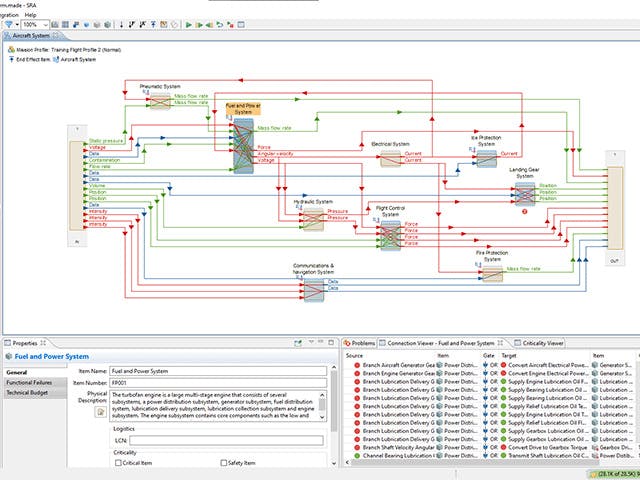

Increase productivity and reduce costs by identifying all possible failures in a design or a product in an objective manner. Produce standard failure mode and effects analysis (FMEA) and FMECA artifacts directly from the digital risk twin; providing the benefits of a reusable/scalable model and the ability to generate standard documents as a by-product of the modeling process at any given point in development process.