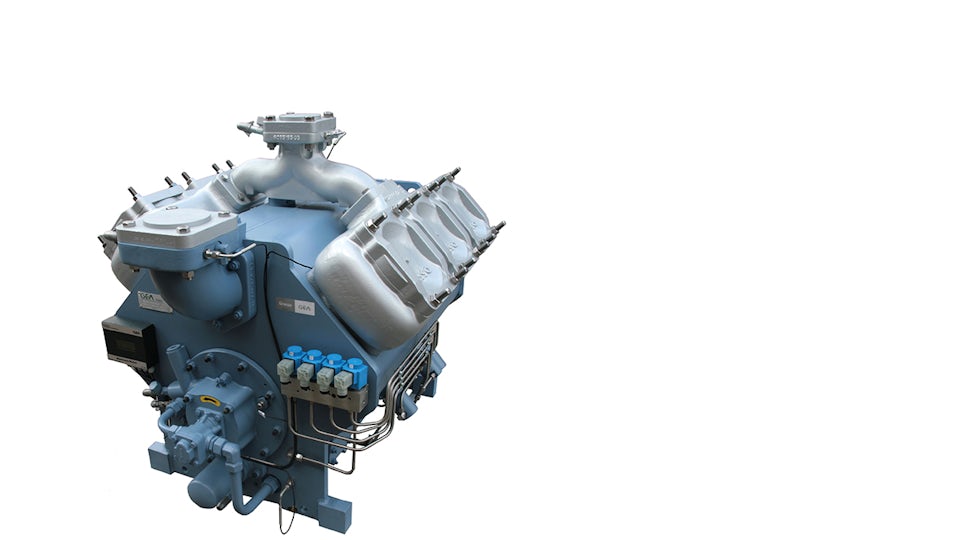

Optimized performance and energy efficiency are essential criteria for driving the development of traditional combustion engines and new hybrid-electric powertrains. However, consumers expect these criteria to come along with high reliability and low noise levels. Additionally, manufacturers strive to design a pleasant product sound that reflects a company’s brand image. Tuning a powertrain to meet all requirements is a complex balancing act.

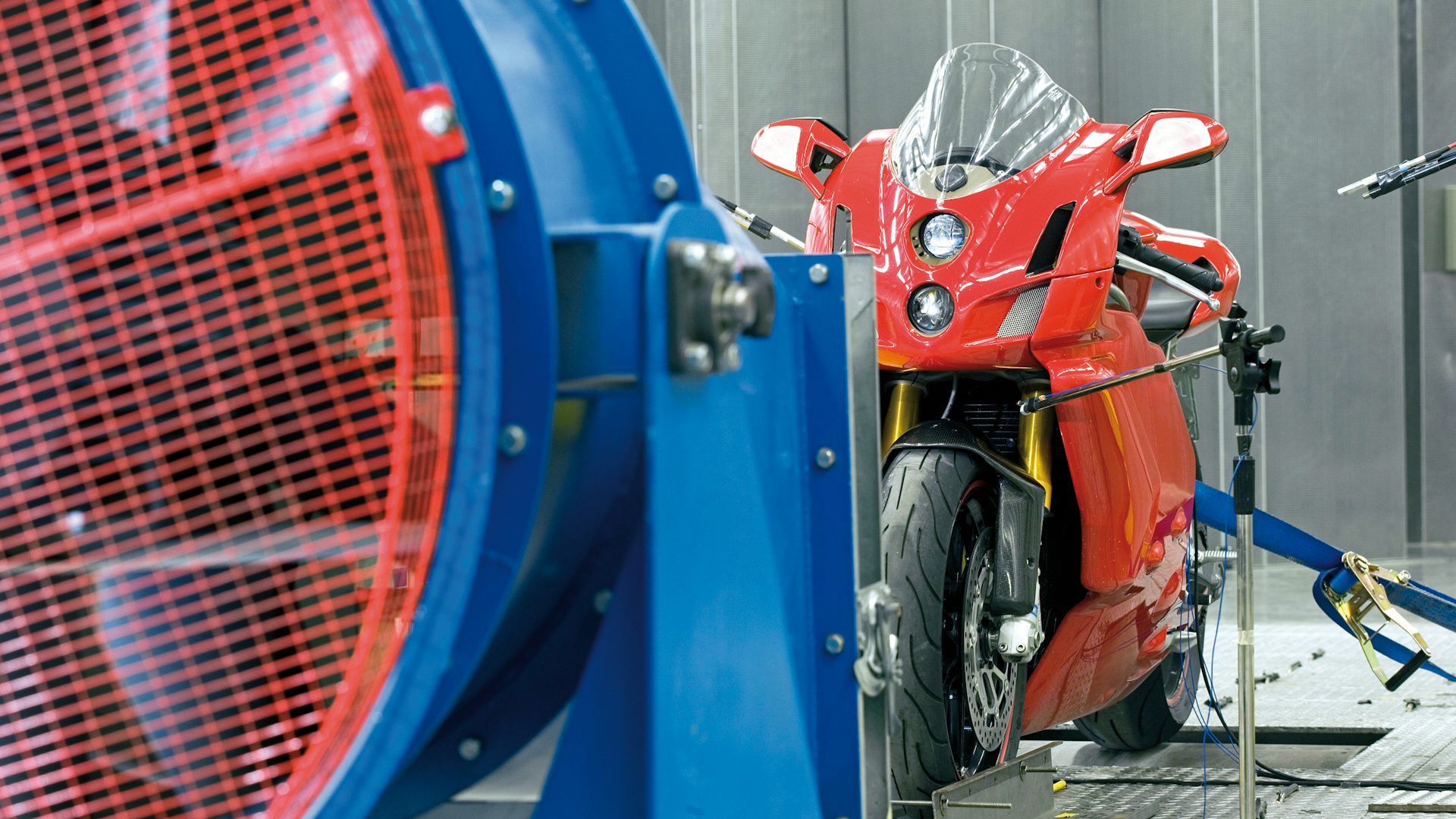

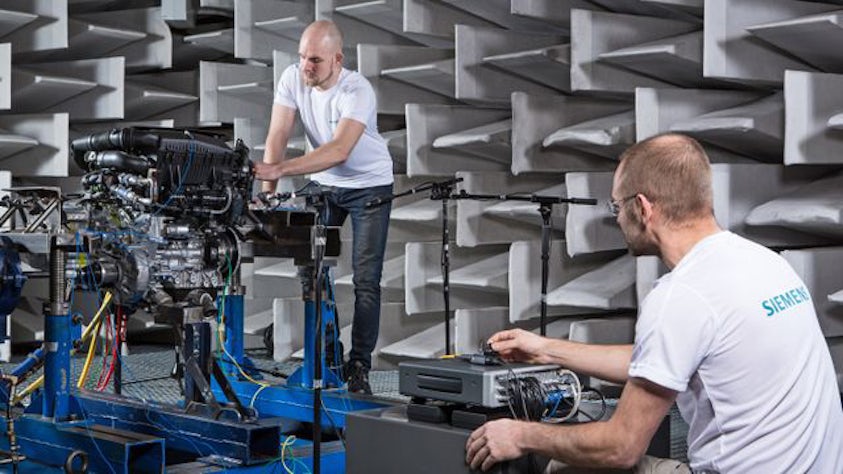

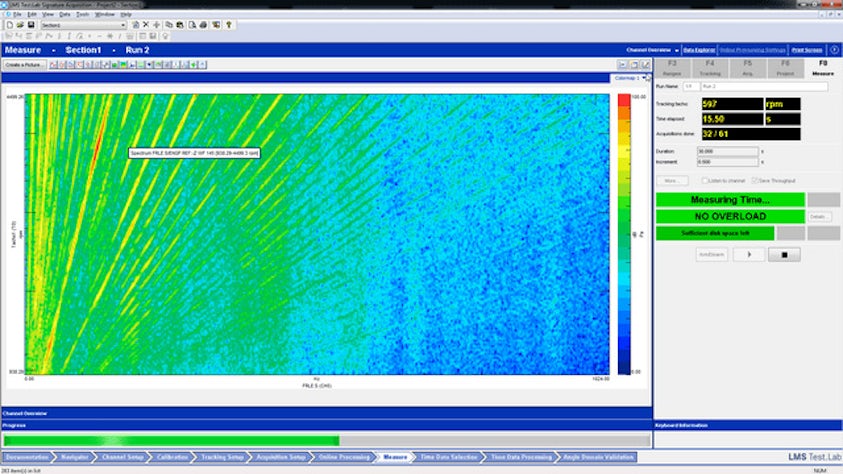

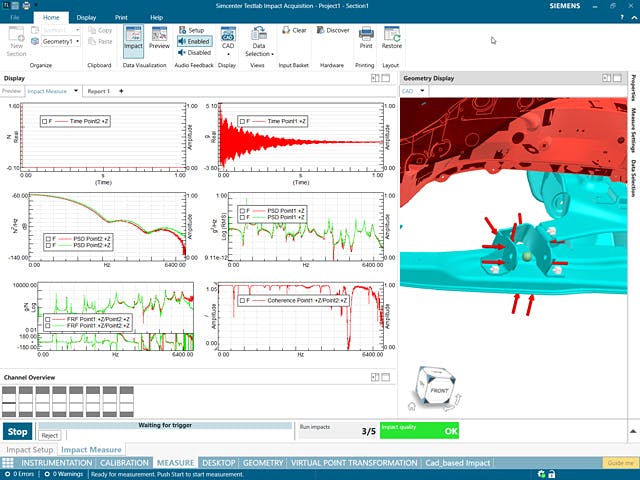

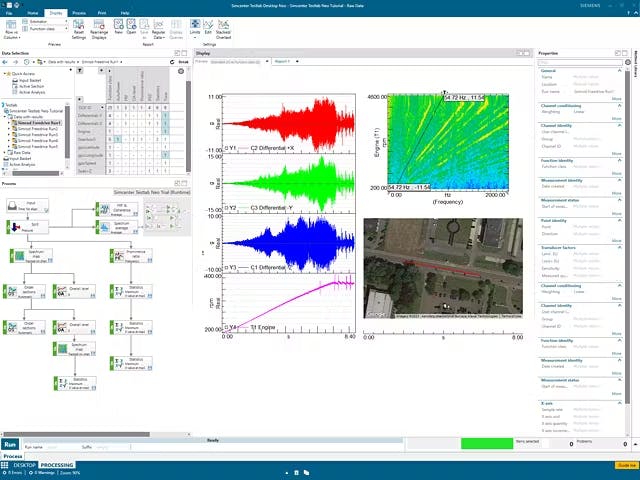

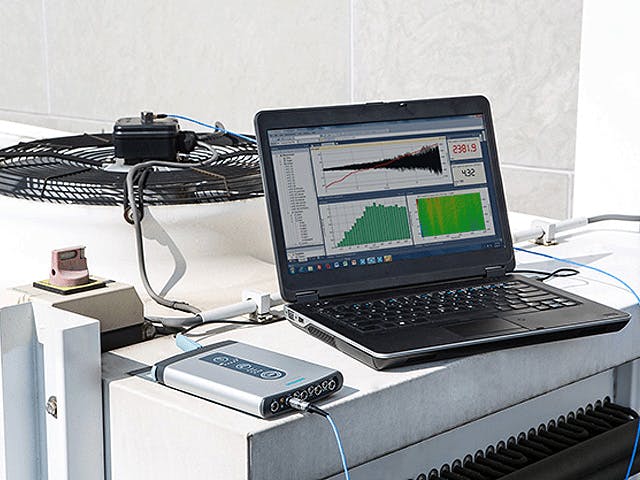

Our rotating machinery testing solutions allow NVH engineers to optimize the performance of rotating machinery, by acquiring and analyzing the impact of speed, torque and control strategies on sound quality, (torsional) vibrations and energy efficiency. In the lab and in the field, our multi-disciplinary testing system saves time, increases data reliability and maximizes insights into the machinery’s behavior.

Next-generation powertrain testing to accelerate the development of green drivelines

Advance powertrain testing and simulation to predict powertrain NVH performance.