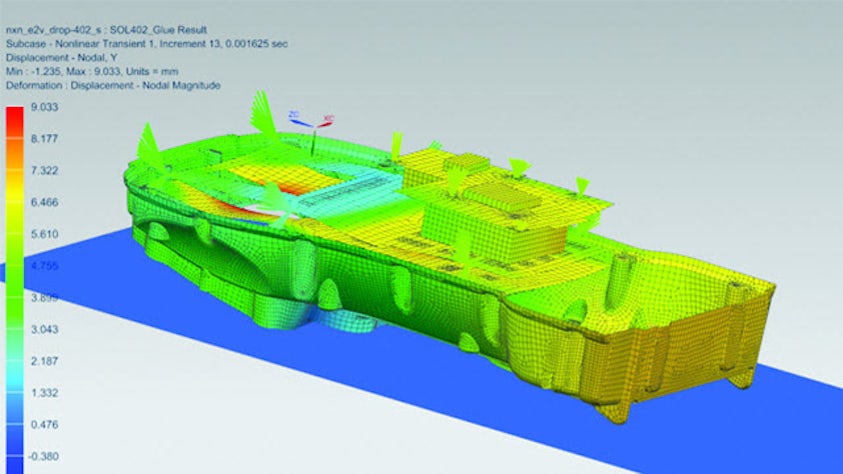

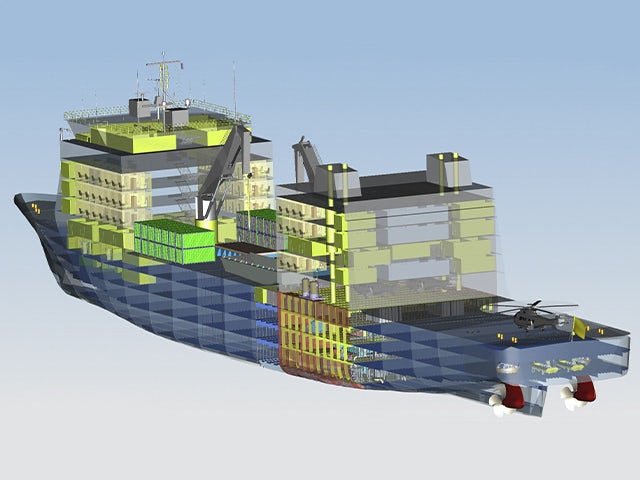

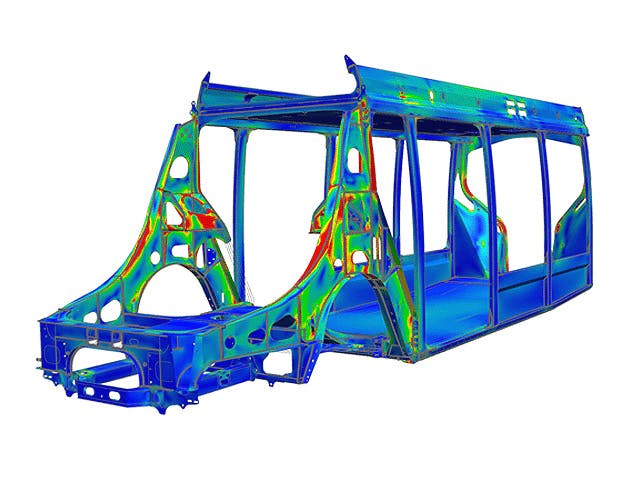

Structural analysis simulation is the study of the effects of weight and tension on a structure. Understanding how a component or product assembly reacts under stress or vibration is critical in any industry. However, as products and materials become increasingly complex, engineers need tools that go beyond linear-statics analyses.

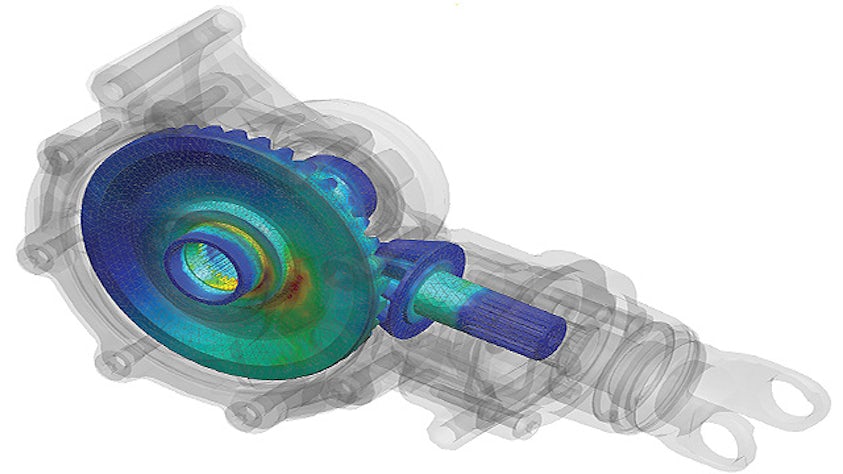

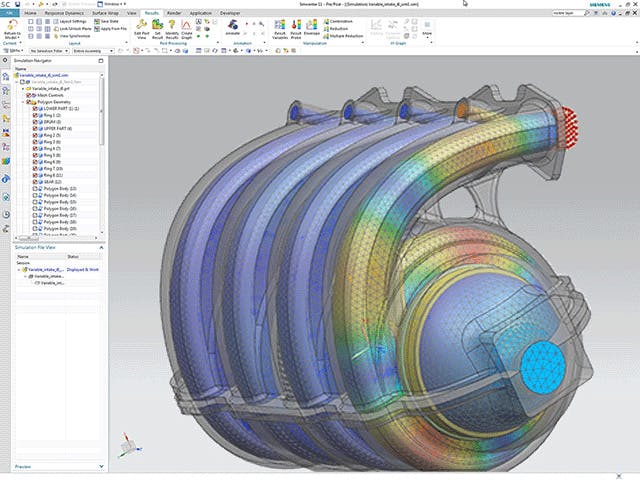

Simcenter provides the structural analysis software you need to simulate a wide range of applications, all within a single user environment. You no longer need one tool for linear statics, another to study fatigue, and yet another for nonlinear analysis. Asa result, engineering departments can consolidate structural analysis tools, and you only need to know a single user interface.

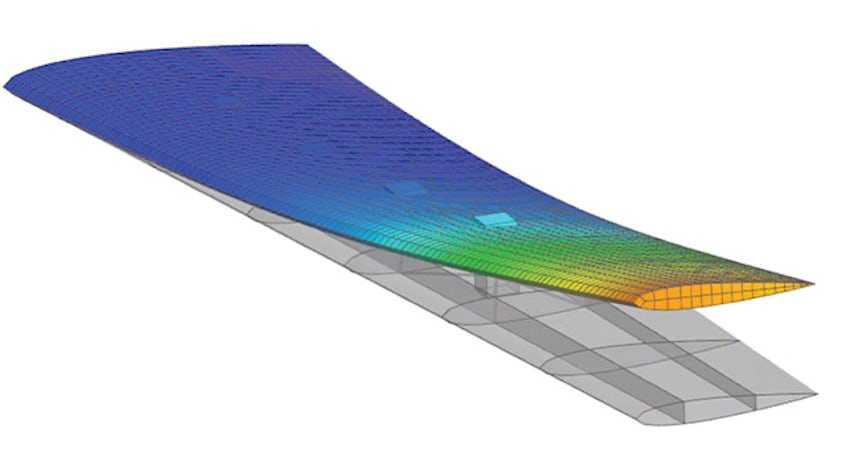

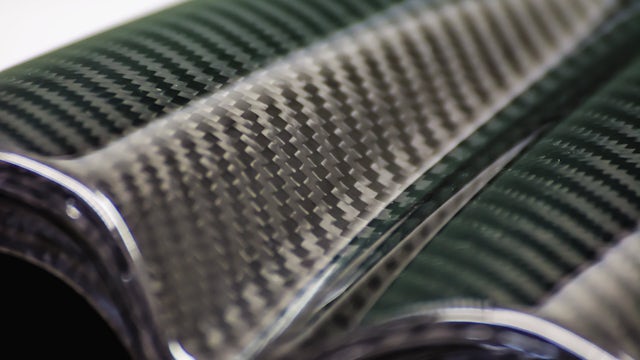

Aircraft structural design and analysis

Moving from fossil fuel-powered aviation to sustainable aviation constitutes a massive engineering challenge but is required to stay competitive. Learn about a connected airframe structural design and analysis approach to enable the evolution of sustainable aviation.