Go faster and explore the possibilities

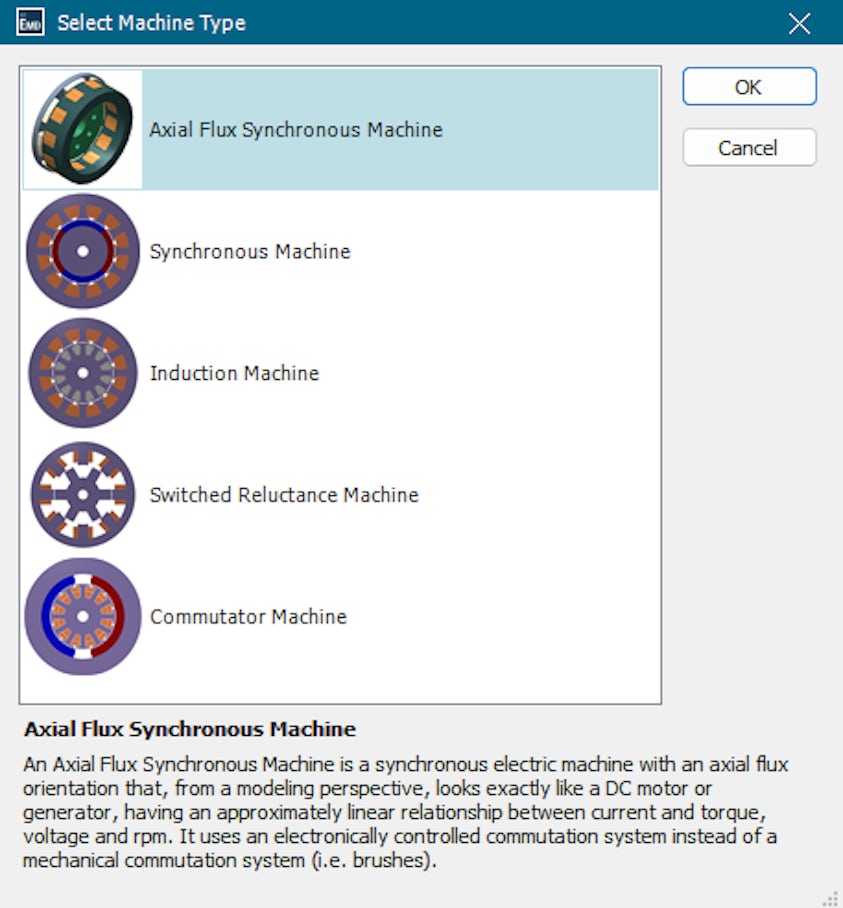

With Simcenter SPEED you can design, test, review and redesign rapidly. With its six fully parametrized templates of the most common motor and generator types, an engineer can produce an initial design in just a few minutes. With full compatibility with HEEDs, the chosen parameters can be investigated or optimized in a design of experiments (DoE) study. With a strong connectivity to Simcenter STAR-CCM+, you can perform further analysis with advanced engineering applications.

Model the complexity

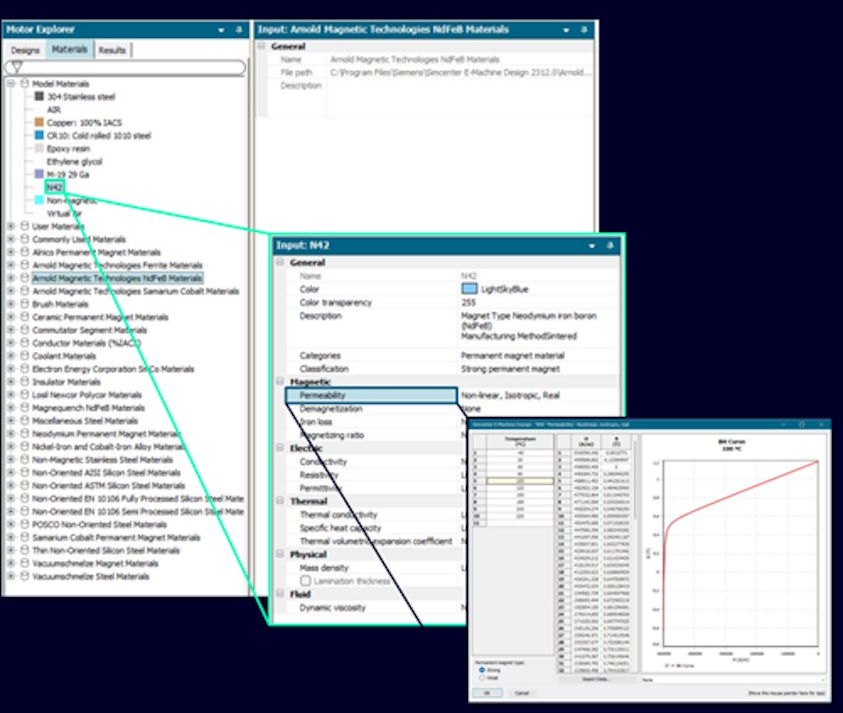

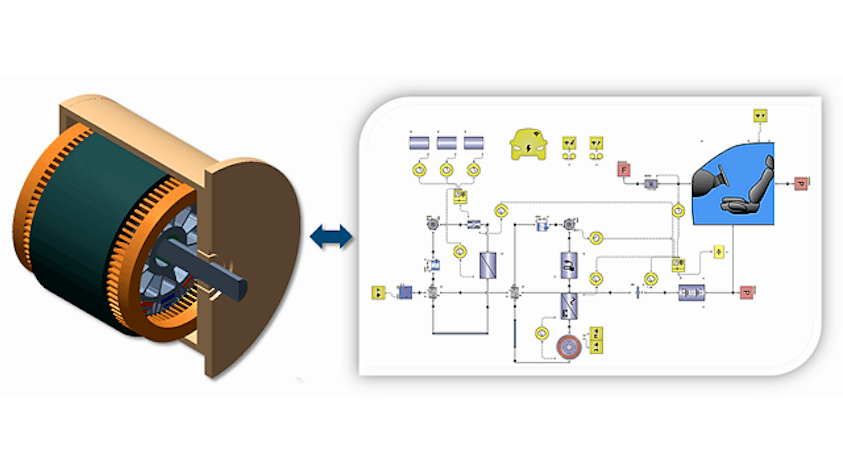

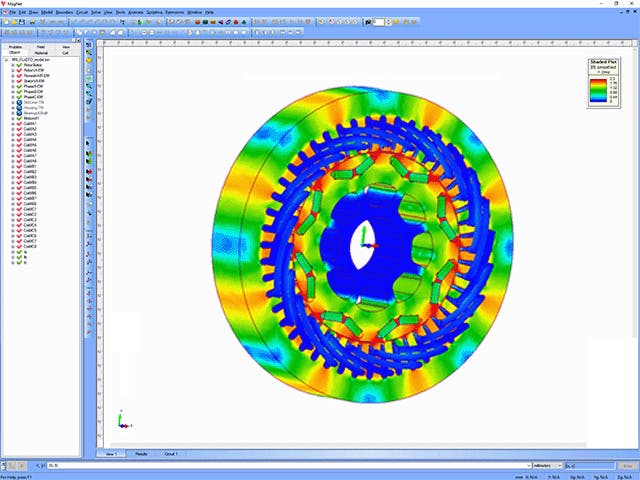

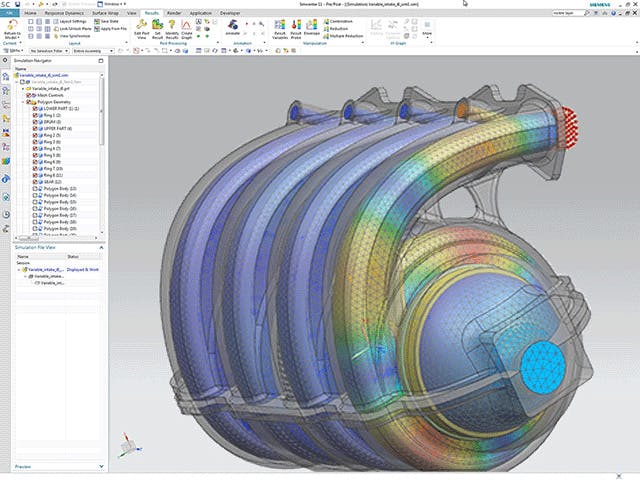

Import your e-machine CAD file directly into Simcenter Motorsolve, where you can optimize your design features, such as coil winding, and benefit from an extensive electromagnetic materials library. With its high-level finite element analysis (FEA) simulation and connectivity to Simcenter MAGNET, an engineer can fine-tune the details of their design with static, time-harmonic, transient and thermal solvers.

Stay integrated

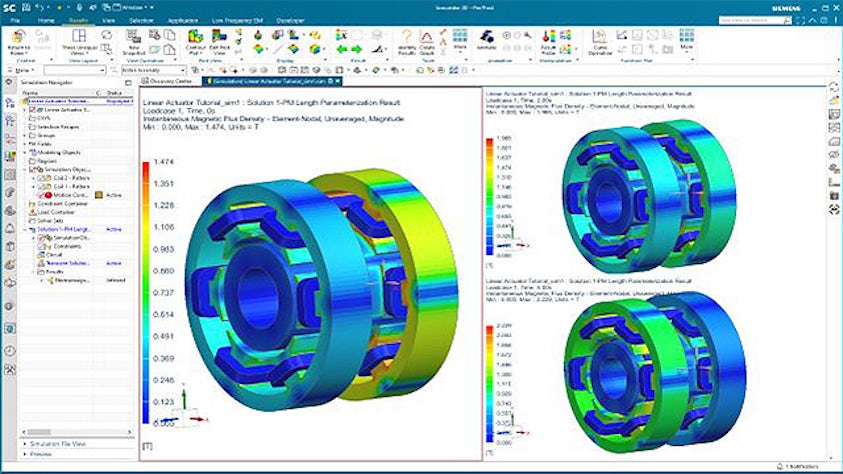

Simcenter 3D low-frequency electromagnetics allows you to create and edit Simcenter MAGNET models in the Simcenter 3D graphical interface with native NX CAD software. Use and define sophisticated magnetic materials and define properties, boundary conditions and loads, including loads using an integrated 1D circuit modeling tool.

Electromagnetic simulations as part of your design process, that’s EMAG-nificent

Electromagnetics (EMAG) and electrical engineers are at home with streamlined EMAG Computer Aided Engineering (CAE) packages, like Simcenter SPEED, Simcenter Motorsolve and Simcenter MAGNET.