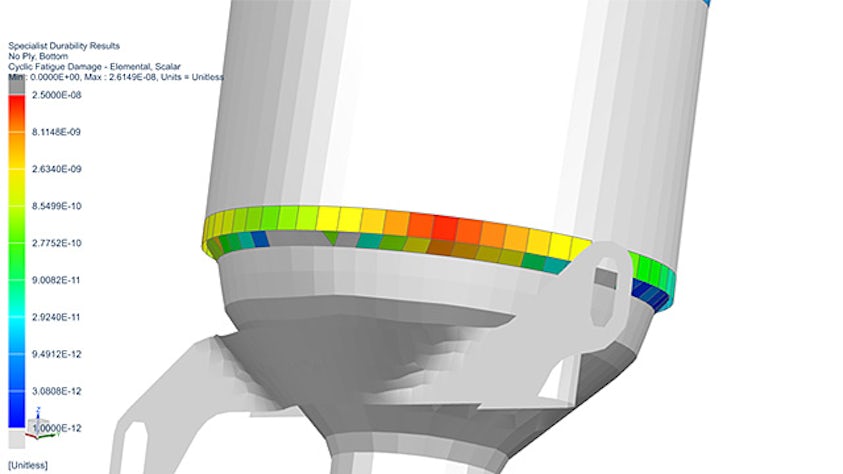

One of the most challenging tasks for durability engineers is designing fail-safe components and systems in the most efficient manner. System parts with insufficient fatigue strength may cause permanent structural damage and potentially life-threatening situations. Mistakes can cause product recalls which negatively influence not only the product but the overall brand image. Shorter development cycles and ever-increasing quality requirements have stretched test-based durability approaches to the limits. Evaluating and refining the durability performance by simulating using durability software methods is the only valid alternative.

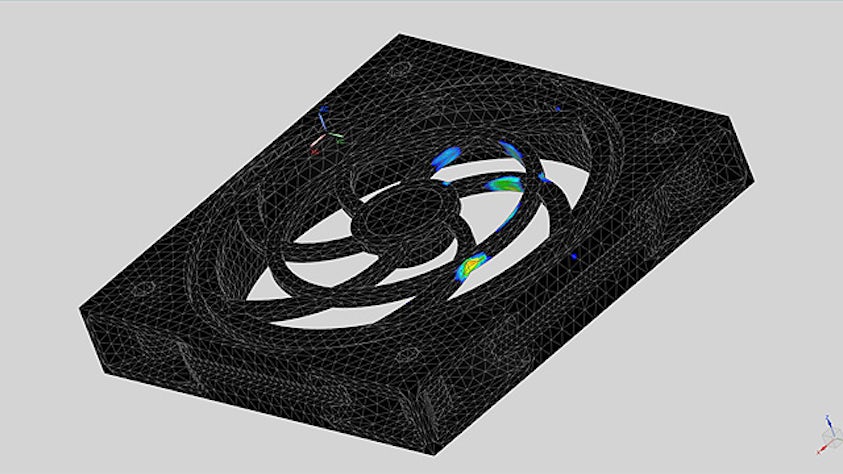

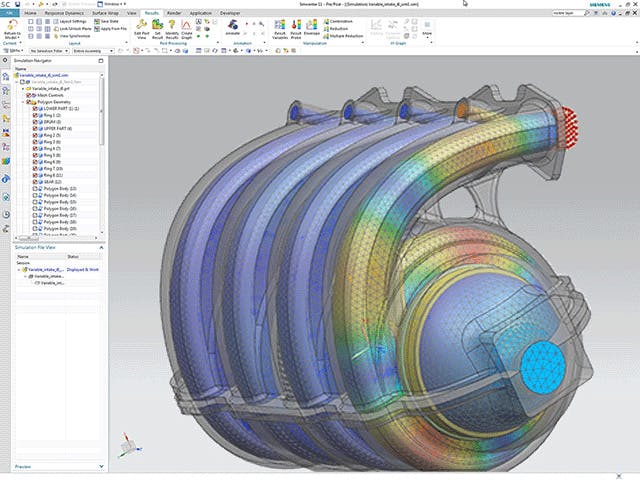

Simcenter gives you access to state-of-the art fatigue analysis methods that enable you to perform fatigue-life prediction analyses quickly and accurately accounting for realistic loading conditions.

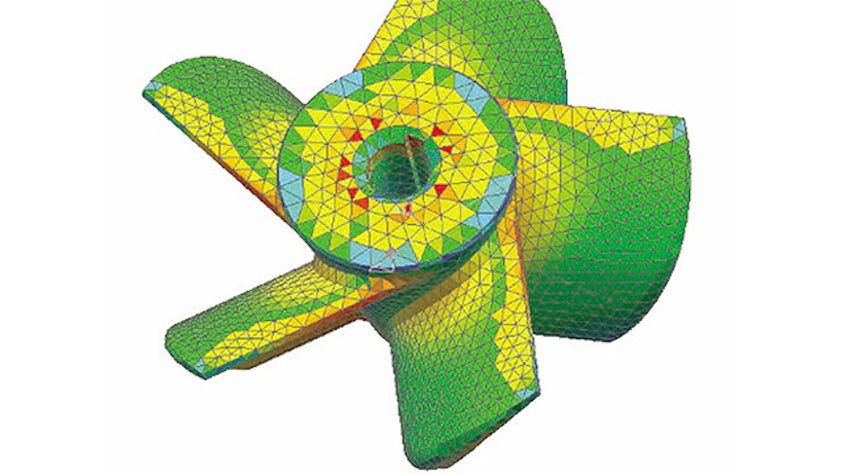

Predicting fatigue performance of additive manufactured parts

Simcenter 3D is a unique fatigue solver that considers AM process-induced local properties in part-scale durability analysis.