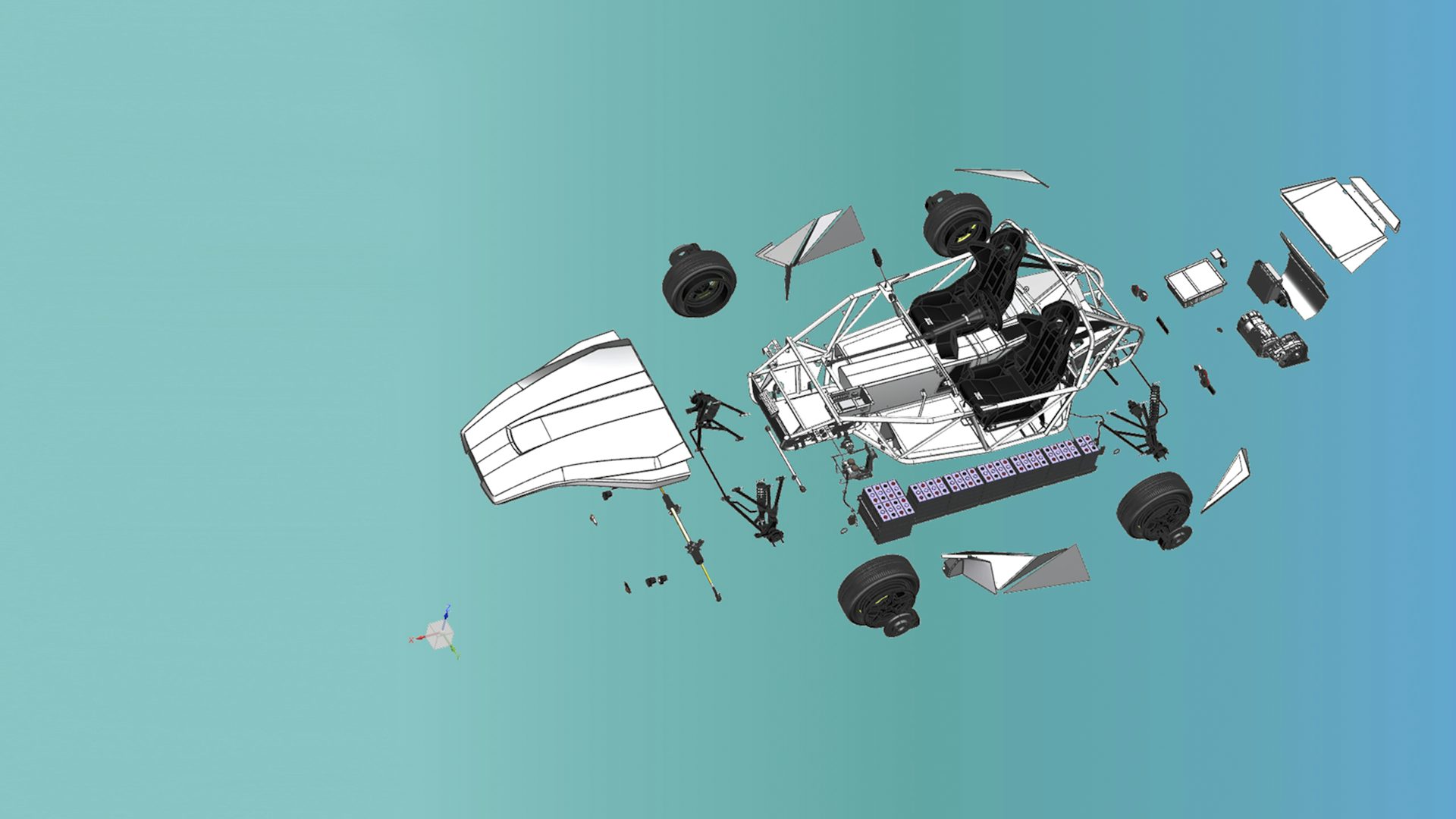

Throughout industries, platform strategies are established reusing complex components across all product variants and the product-prototype availability for testing and NVH performance assessment is drastically reduced. Furthermore, there is the shift towards electrical propulsion in the automotive industry: engineers must investigate new powertrain concepts with complex load cases and have to take into account the increased importance of road noise and secondary noise sources.

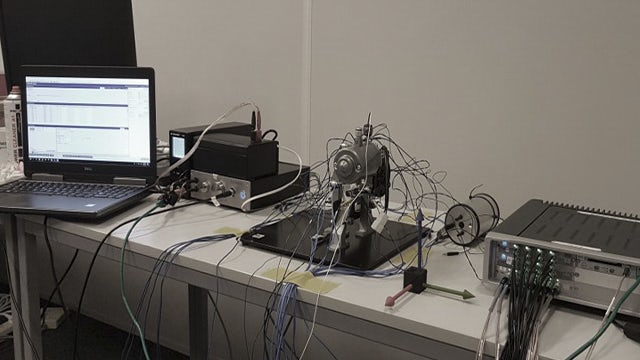

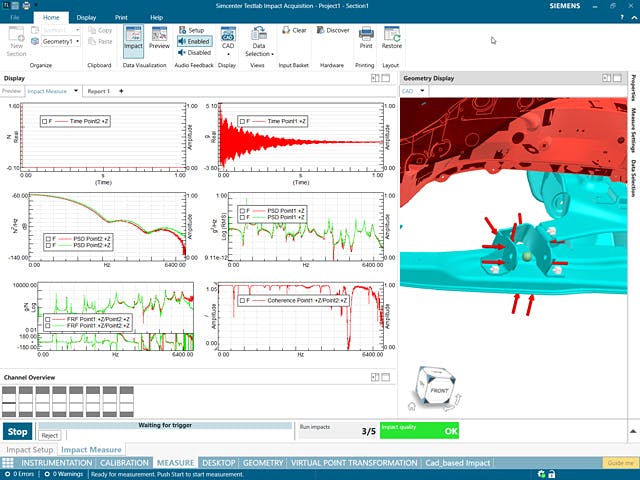

Component-based TPA is a technology that addresses these challenges. It allows to model a noise source component independently from the receiver structure and predict its behavior when coupled to different receivers. This frontloads development which considerably increases design flexibility. The method allows component suppliers to characterize their product independently from the receiver product and to predict the interface interaction with the receiving structure and noise comfort of the final product.

The net result prevents late troubleshooting, costly troubleshooting activities and expensive design modifications. It also assists in knowledge perseverance since the key expert knowledge is embedded in a model-based development process.