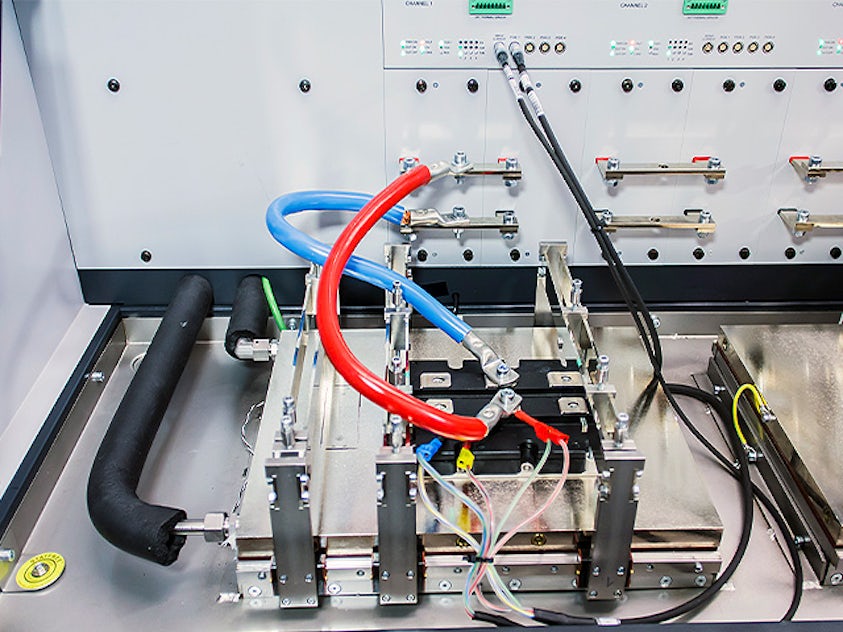

Simcenter Micred T3STER is an advanced non-destructive transient thermal tester for the thermal characterization of packaged semiconductor devices (diodes, BJTs, power MOSFETs, IGBTs, power LEDs) and multi-die devices. It measures the true thermal transient response more efficiently than steady-state methods. Measurements are to ±0.01° C with up to 1-microsecond time resolution. Structure functions post-process the response into a plot that shows the thermal resistance and capacitance of package features along the heat flow path. Simcenter Micred T3STER is an ideal pre- and post-stress failure detection tool. The measurements can be exported for thermal model calibration, underpinning the accuracy of the thermal design effort.

Enable faster results with just one test

Simcenter Micred T3STER is easy to use and fast. It produces fully reproducible results, so each test only needs to be carried out once. Simcenter Micred T3STER tests packaged ICs using only electrical connections for powering and sensing, giving fast, repeatable results and eliminating the need for multiple tests on the same part. Components can be tested in situ and test results can be used as a compact thermal model or to calibrate a detailed model.

Test all type of packaged semiconductors

Practically all types of packaged semiconductors can be tested, from power diodes and transistors to large and highly complex digital ICs, including parts that are mounted on a board, and even packaged into a product.

Simply put, a power pulse is injected into the component and its temperature response is recorded very accurately against time. The semiconductor itself is used both to power the part and to sense the temperature response using a temperature-sensitive parameter on the die surface such as a transistor or diode structure.

Access reliable software

The software provided with Simcenter Micred T3STER provides a lot of the value of the solution. That’s because the Simcenter Micred T3STER software can take the temperature versus time trace and convert it into what is known as a structure function. Discrete features of the package, such as the die attach can be detected in this plot, making Simcenter Micred T3STER an excellent diagnostic tool in product development. The plot can also be used to calibrate a detailed 3D thermal model in Simcenter Flotherm, creating a thermal model of a chip package that predicts temperature in both space and time with 99+% accuracy.

Achieve higher accuracy in electronics cooling simulation with measurement and calibration

This whitepaper considers factors for higher accuracy for modeling trace and connection heat dissipation within simulation. It illustrates thermal measurement of an IGBT module using Simcenter T3STER and model calibration in conjunction with thermal simulation in Simcenter Flotherm.