Simcenter SPH Flow is a rapid meshless computational fluid dynamics (CFD) tool that provides designers and analysts a fully integrated environment. Enabling sophisticated CFD earlier in the development cycle, it uses the innovative smoothed-particle hydrodynamics (SPH) method.

Reduce set up and solving times

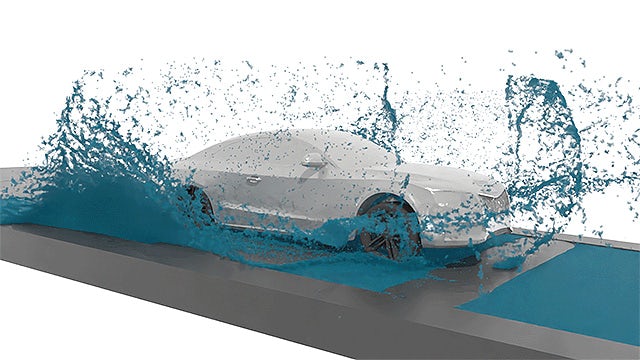

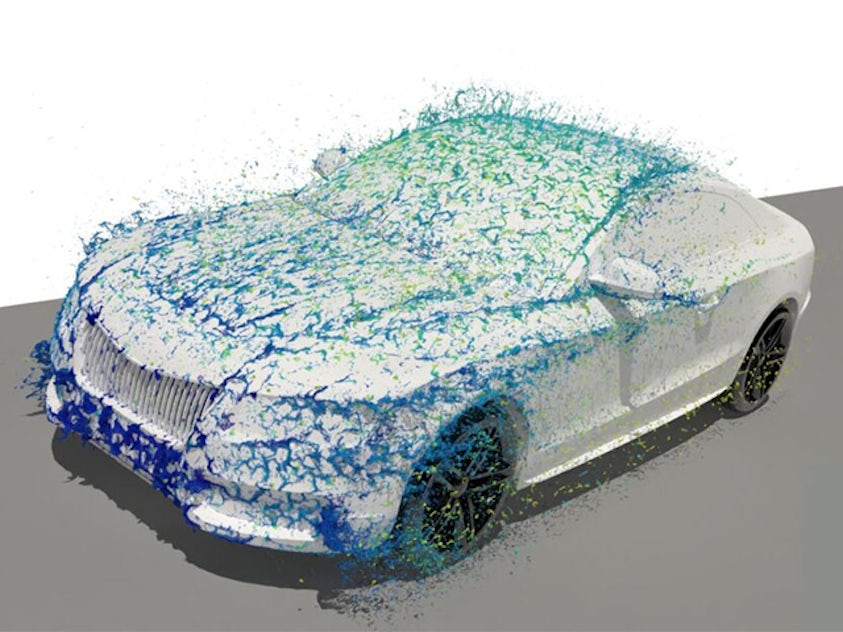

Easily handle complex geometries and motions with a rapid and robust meshless method. Resolve complex highly dynamic fluid/fluid interface with no extra effort. Automate your process with a guided step-by-step workflow.

Leverage on a meshless method

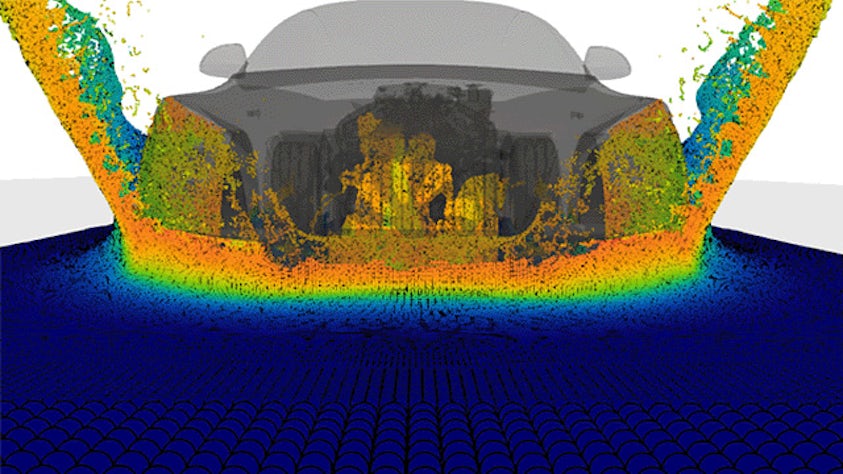

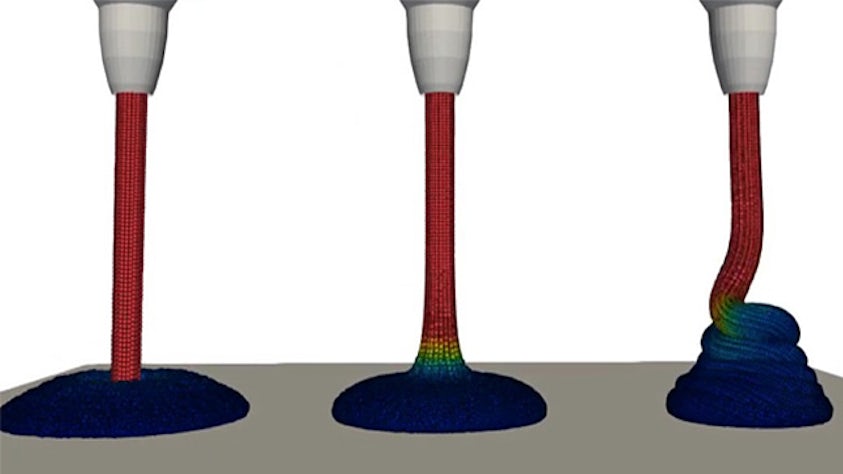

The smoothed-particle hydrodynamics (SPH) method is part of a new generation of numerical methods, developed to overcome meshing-related constraints with traditional approaches while still being based on the Navier-Stokes equations. With its Lagrangian characteristic and its particle-based approach, Simcenter SPH Flow is particularly well suited for highly dynamic flows, deformable and complex boundaries, and interfaces with fragmentations/ reconnections.

Analyze complex transient applications

Benefit from a detailed analysis of dynamic flows at no additional cost. Precisely capture areas of interest with adaptive particle refinement.

Stay integrated

Get a better insight of lubrication oil trajectory considering air friction. Ensure optimal performance considering temperature coupling. Improve reliability considering fluid-structure interactions.

What’s new?

Run faster simulations through efficient solid boundary condition treatment. Easily set up fluid-structure one-way coupling interactions. Model the complexity of mixing applications with multiple liquids.