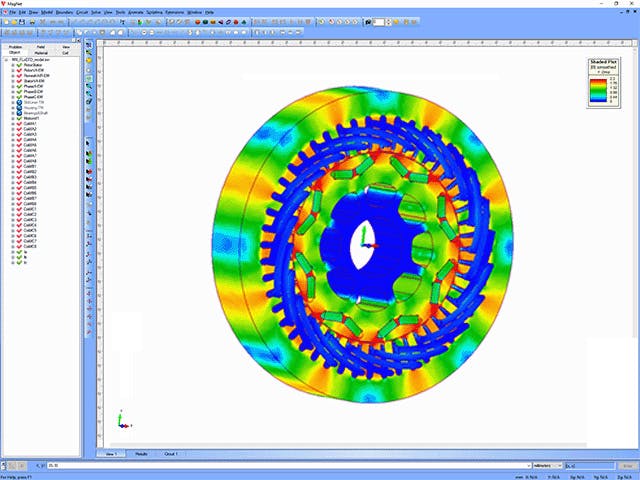

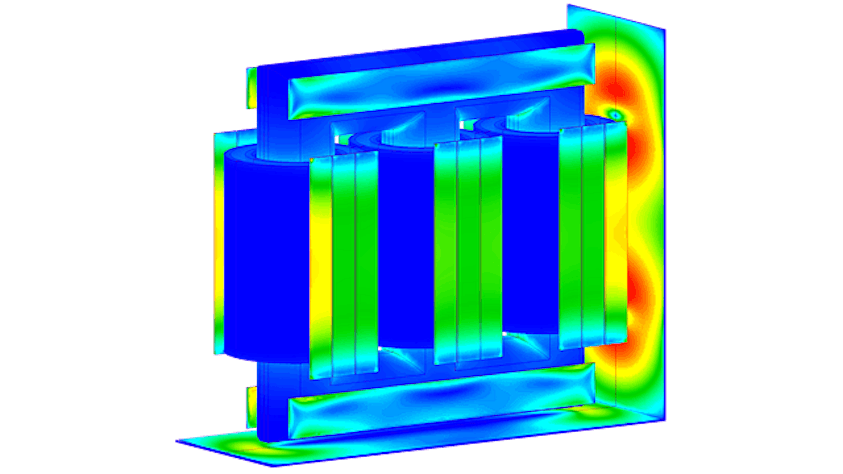

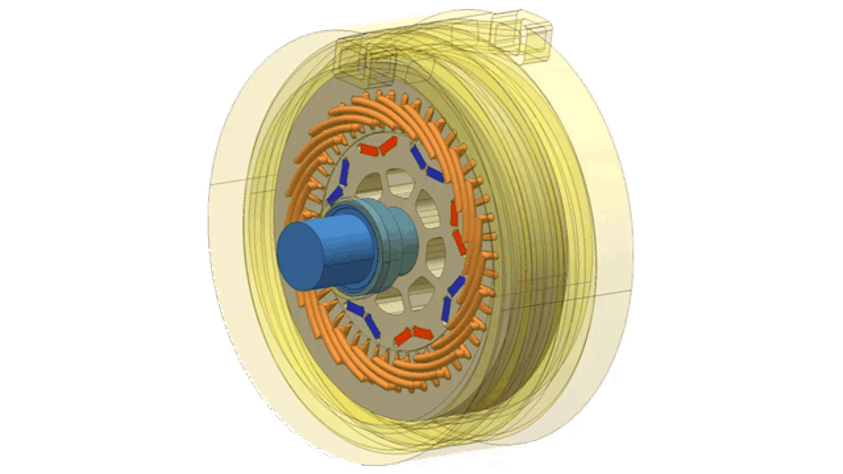

Simcenter MAGNET is a powerful electromagnetic field simulation solution for performance prediction of motors, generators, sensors, transformers, actuators, solenoids or any component with permanent magnets or coils.

Model the physics of electromagnetic devices

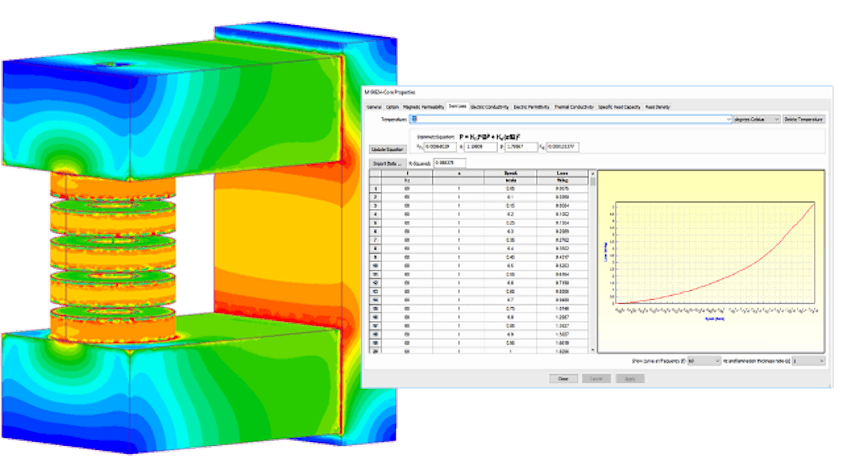

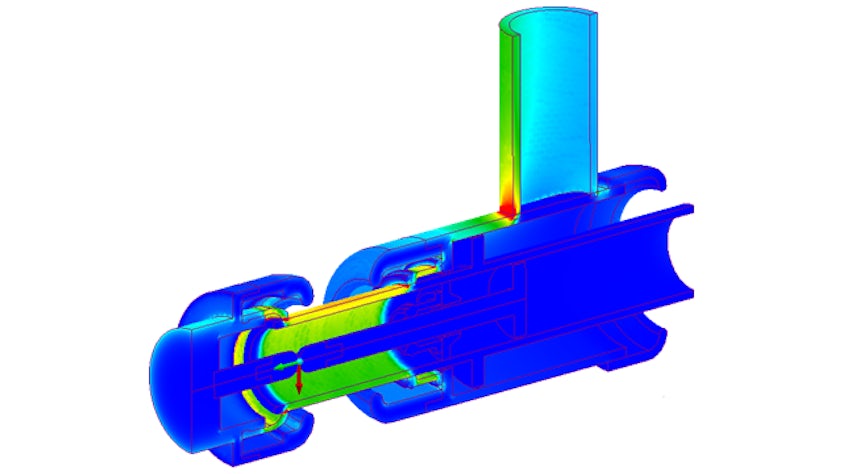

Simcenter MAGNET includes capabilities to accurately model the physics of electromagnetic devices. This includes the ability to model manufacturing processes, temperature dependent material properties, magnetization and de-magnetization modeling, and vector hysteresis models among others.

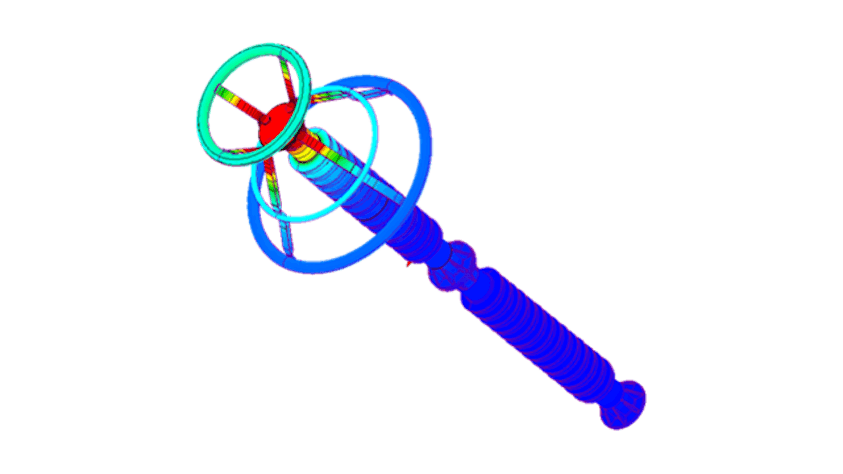

Simcenter MAGNET also has a built-in motion solver with a six degree-of-freedom capability. It allows for complex problems like magnetic levitation or complex motion to be accurately modeled and analyzed. This is made possible with a unique smart re-meshing technology.

Explore the possibilities through simulation automation

An efficient design process requires tools which can be customized to the workflow. Simcenter MAGNET includes sophisticated scripting capabilities that allow for flexible workflow automation.

Using the Simcenter MAGNET fully parameterized CAD functionality will improve the efficiency of your simulation. In particular, models that would ordinarily require a lot of manual processes, such as those that include numerous calculations for various magnets with different dimensions and many air gaps.

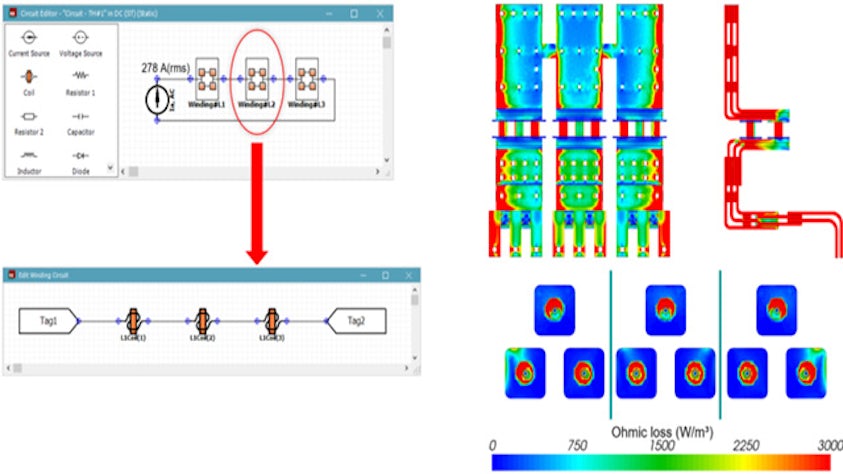

Stay integrated with circuit to system level modeling

System-level (1D) or model-based (2D axisymmetric, 2D translational, and full 3D) analysis requires accurate sub-component models to account for interactions and local transients that affect the overall system behavior.

Simcenter MAGNET includes capabilities such as native circuit simulations, connections for co-simulation and exporting of 1D system models for Simcenter Flomaster, Simcenter Amesim and other platforms.