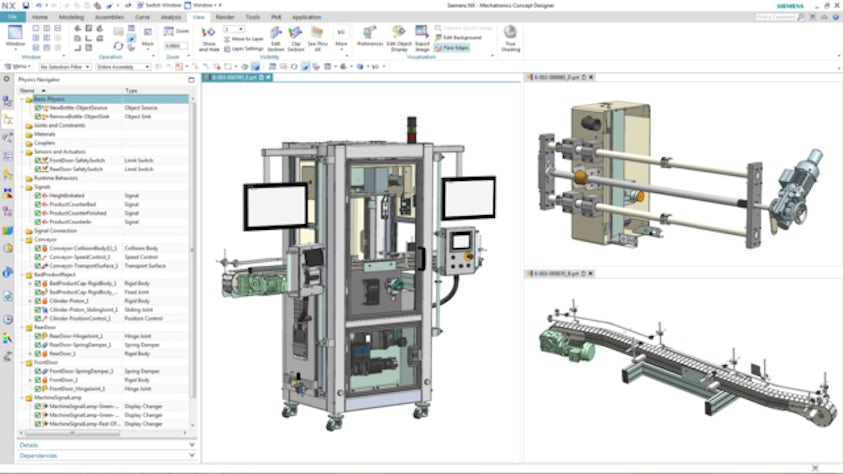

Use the output of Mechatronics Concept Designer to continue to refine designs without the need to remaster the data—this can be done directly by multiple disciplines.

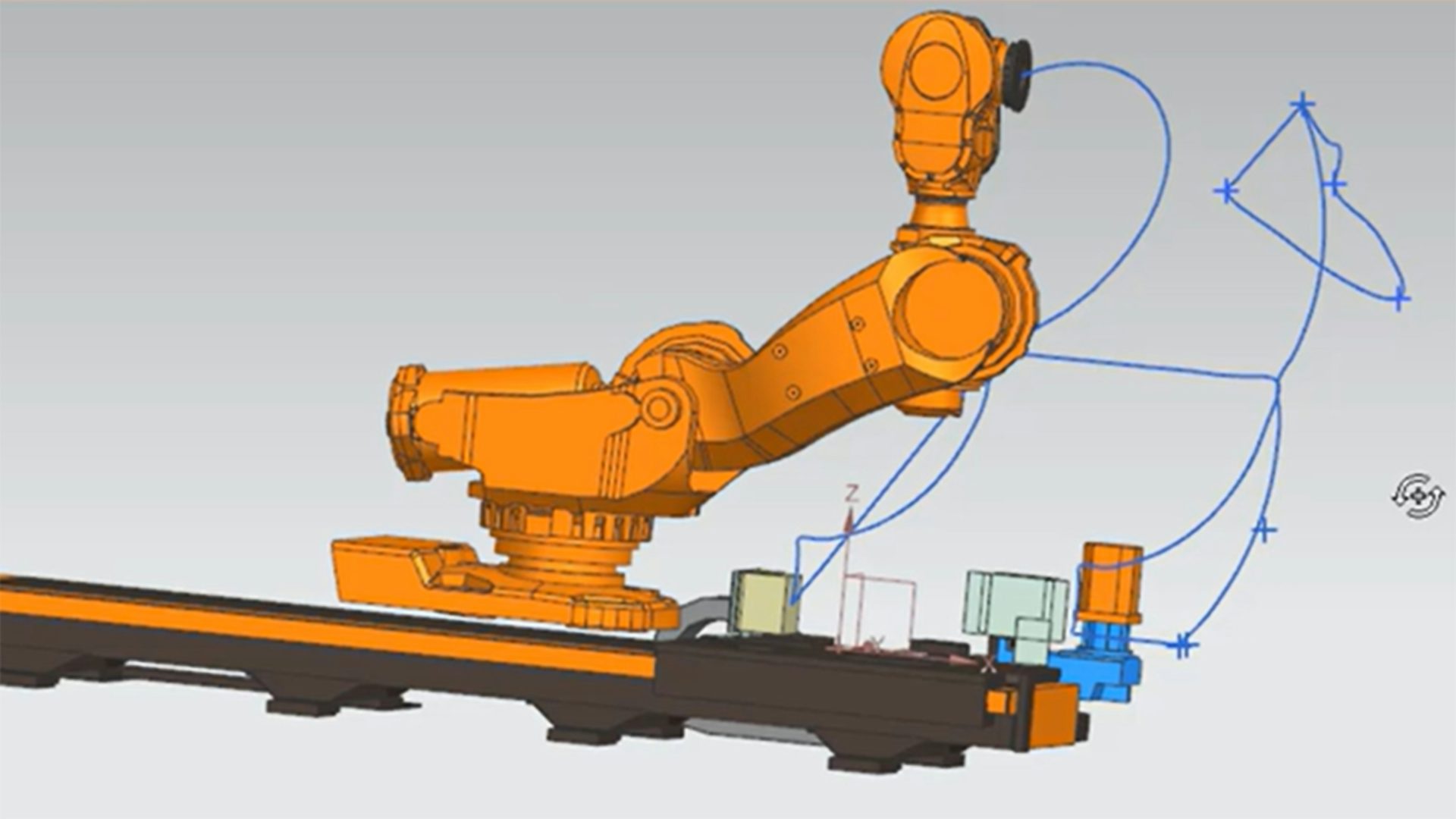

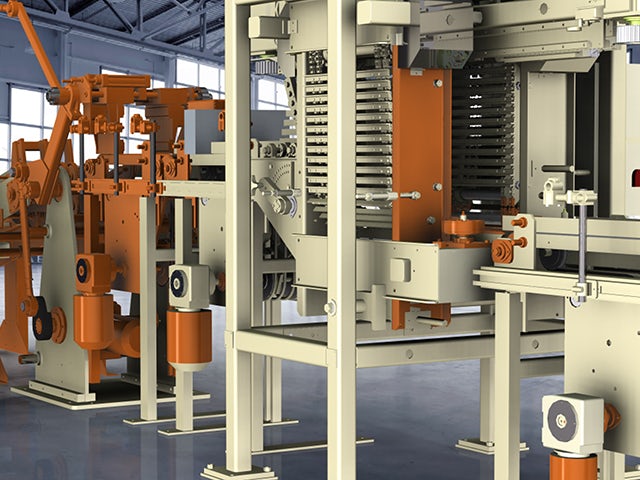

- Mechanical designers can use concept models in NX for detailed design

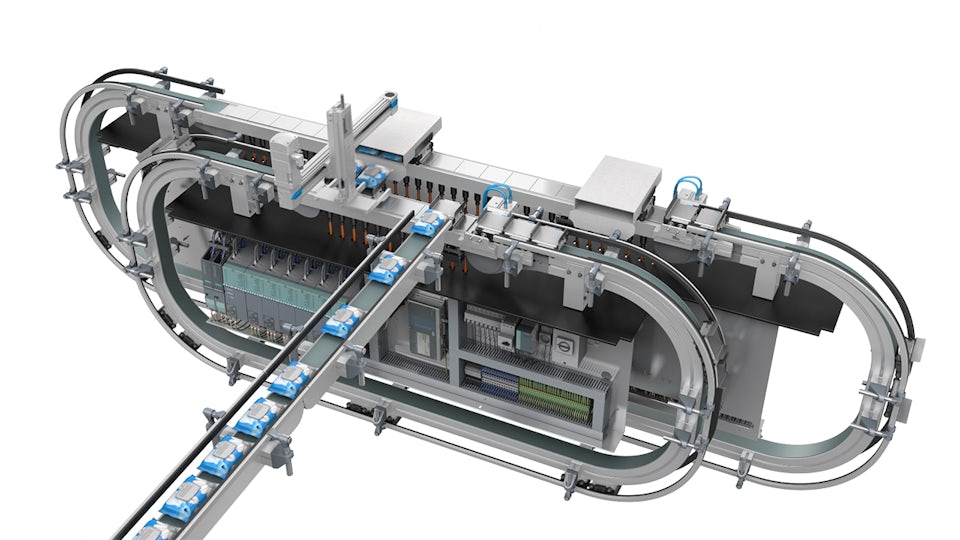

- Electrical designers can use model data to select sensors and actuators

- Automation designers can use cams and operation sequence information from the model for software development