Advanced technologies to improve tooling development

Accelerate the development of even the most challenging tooling and fixture designs using the automated capabilities in NX software.

Explore the powerful design capabilities for tooling and fixtures:

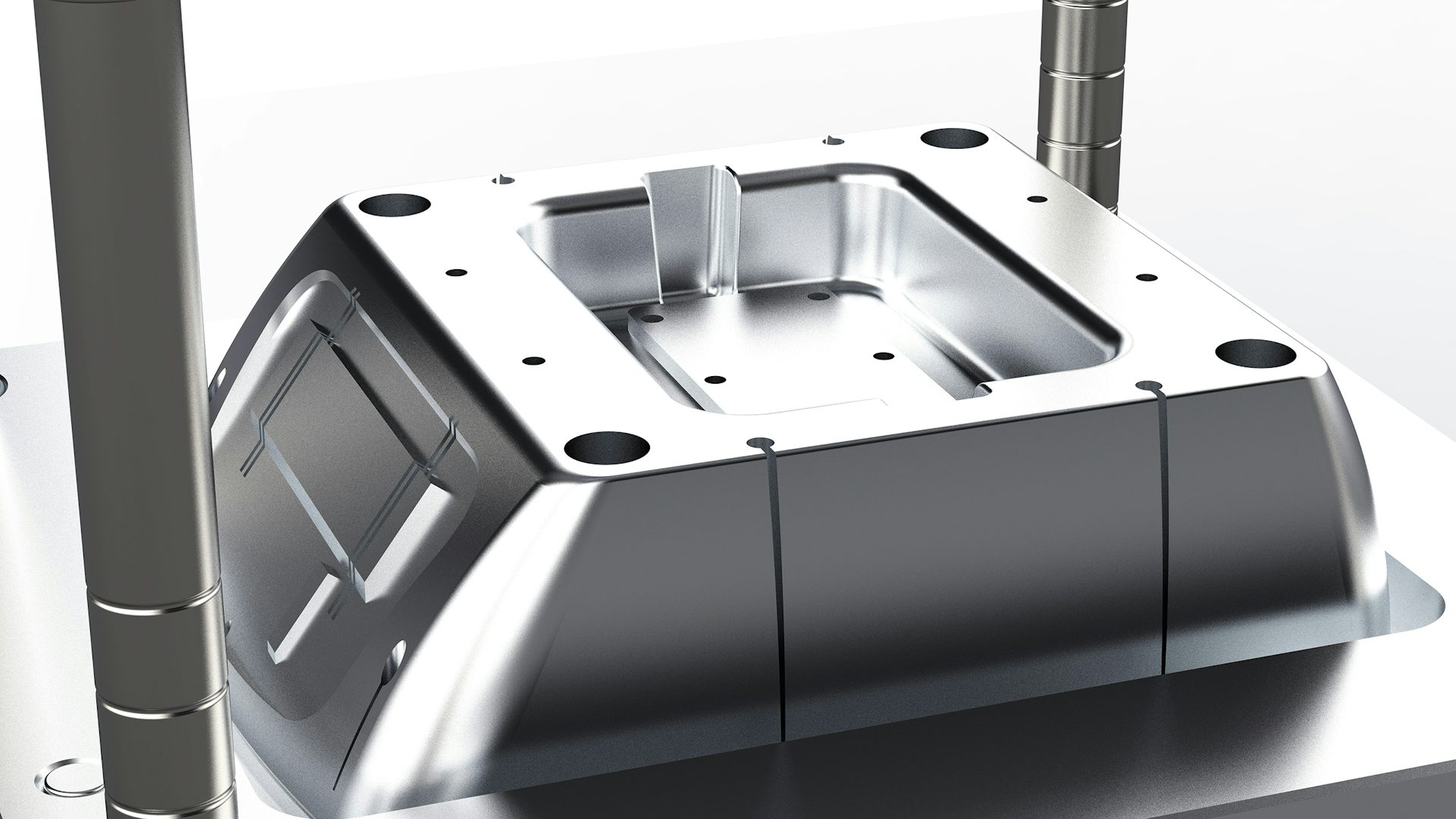

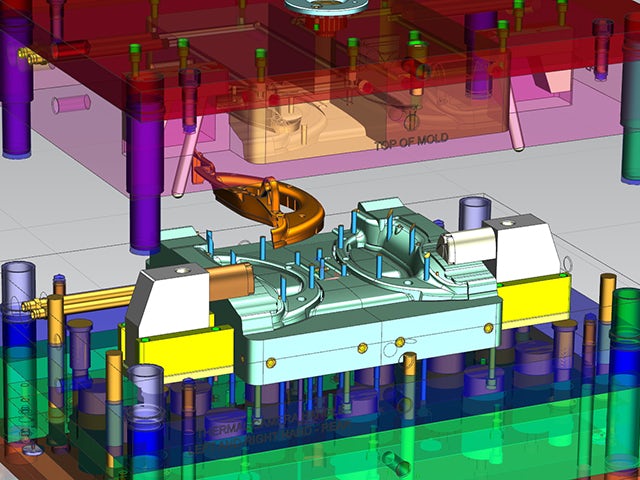

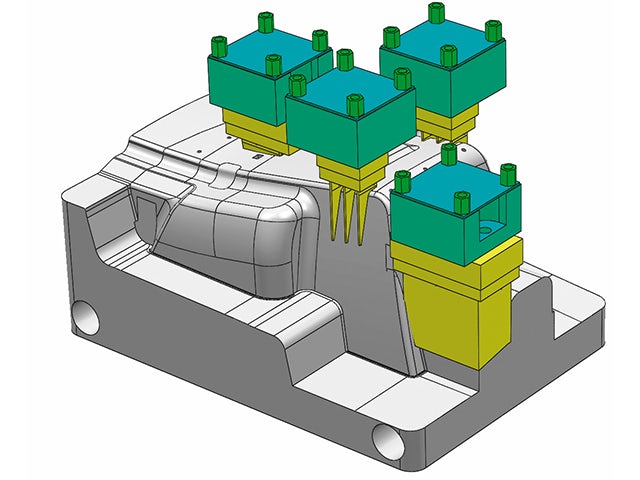

Mold design

Accelerate the mold development process using advanced tools to validate part design, tool design and motion.

Configure the mold structure using libraries of standard parts, component systems and mold bases.

Advanced functionality, step-by-step guidance, and associativity with the part model ensure fast response to design changes and quality molds.

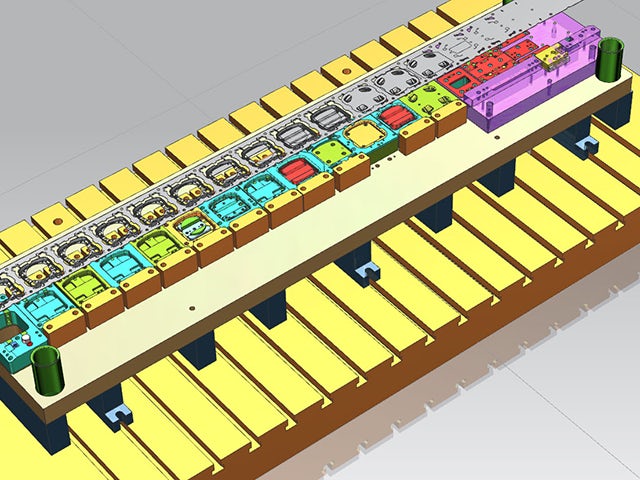

Progressive die design

Improve productivity by automating the most tedious tasks and streamlining complex processes of progressive die design.

Use the comprehensive solution for both straight break and freeform sheet metal parts, while maintaining associativity to the part design at every stage.

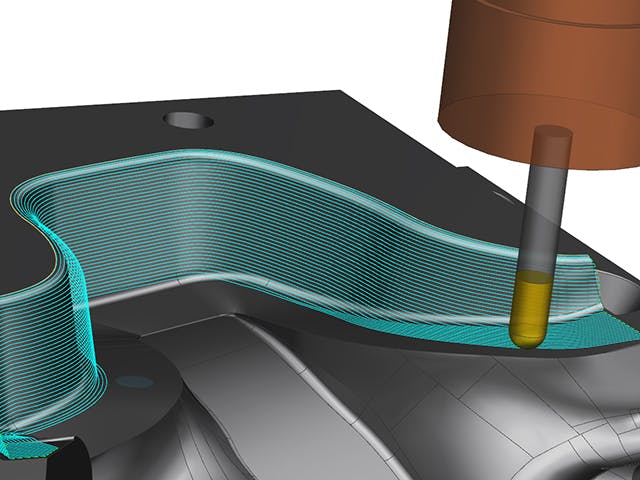

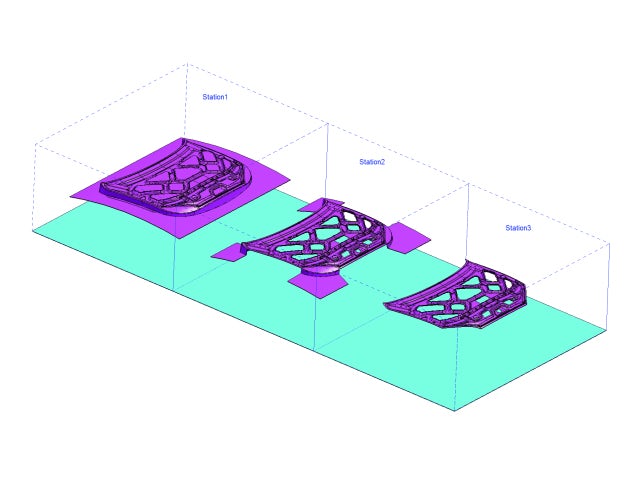

Stamping die design

Use advanced capabilities to design automotive stamping dies, including formability analysis, die planning, die face design, detailed die structure design and die validation.

The solution guides you in defining the manufacturing process for complex stamped parts, providing representations of the press line and sheet metal shape as it leaves each press.

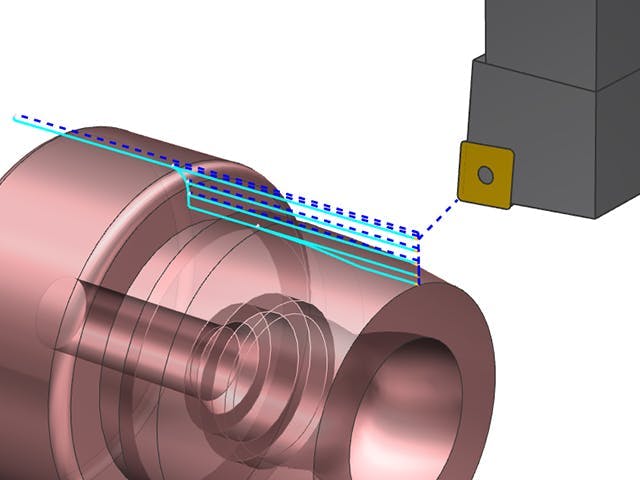

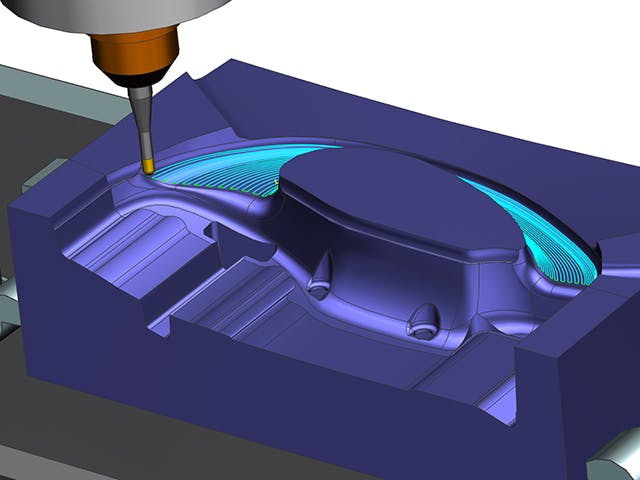

Electrode design

Automate the entire electrical discharge machining (EDM) process—from design through production. The powerful capabilities help you efficiently model even the most complex and challenging electrodes.

The electrode design is associative, ensuring that the design changes made to the core and cavity seamlessly propagate to the electrode and into machining.

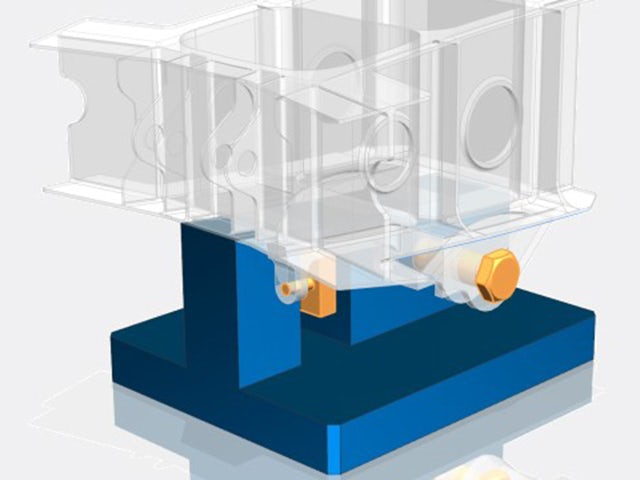

Fixture design

Accelerate the design of jigs and fixtures that are fully associative to the 3D part model by using the latest dynamic modeling and assembly tools.

Easily position fixture components using interactive assembly capabilities, and then automatically create drawings and documentation.

Simulate the kinematics of fixtures, such as opened and closed positions, and check for strength and distortion.

Cavalier Tool and Manufacturing

Award-winning mold manufacturer relies on NX

Company:Cavalier Tool and Manufacturing

Location:Windsor, Ontario, Canada

Siemens Software:NX

Explore NX for manufacturing products

Get more details about our wide range of solutions for your specific part manufacturing needs.

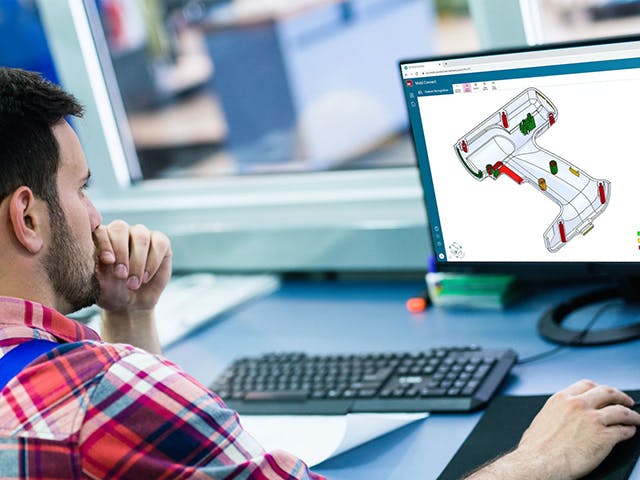

Siemens Teamcenter Share

Optimize your entire production process with Teamcenter Share, a cloud-based collaboration solution, which seamlessly connects to NX CAM software. Securely communicate and share information with internal and external stakeholders in the cloud.

Connect design, manufacturing and shop floor teams to run more flexible and efficient production.