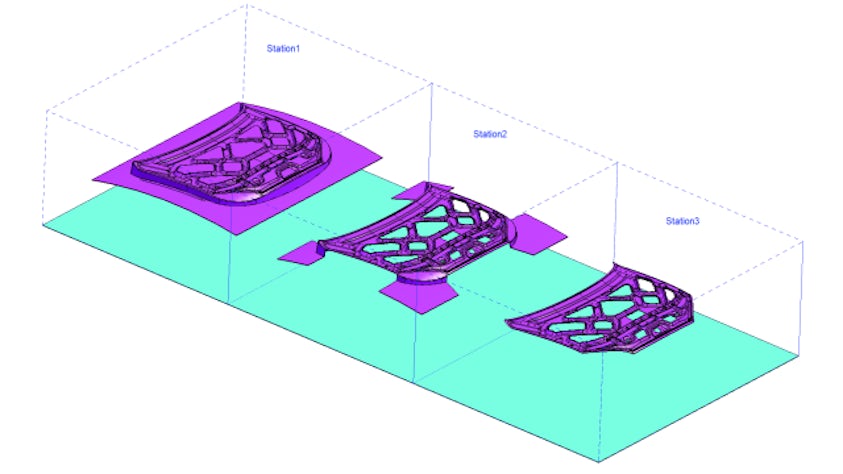

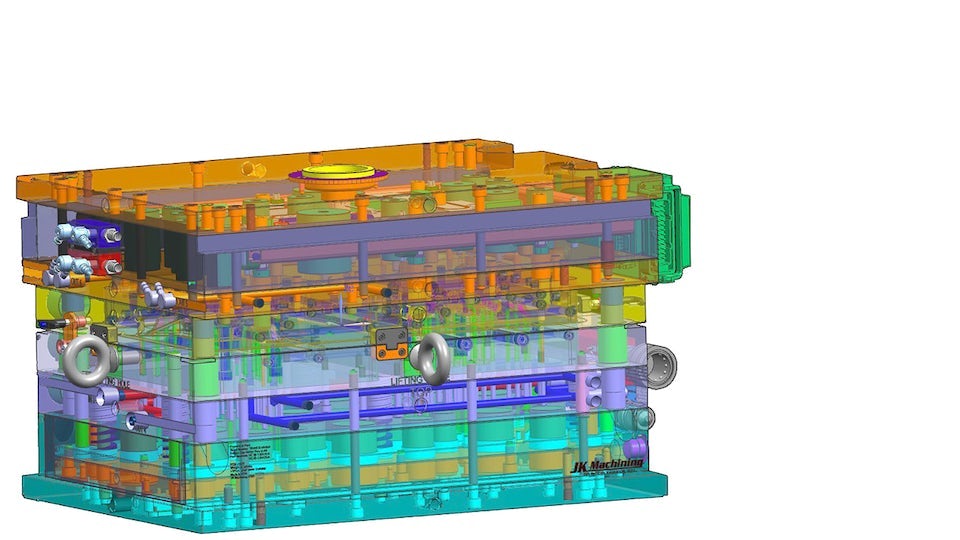

Design accurate stamped parts

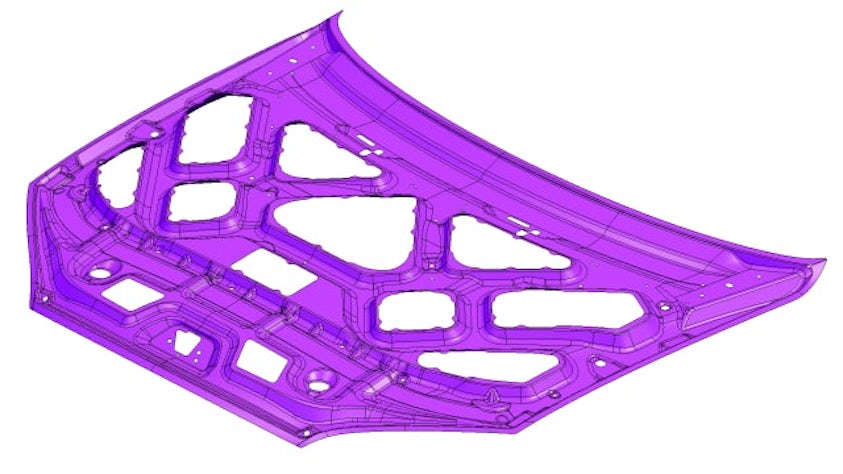

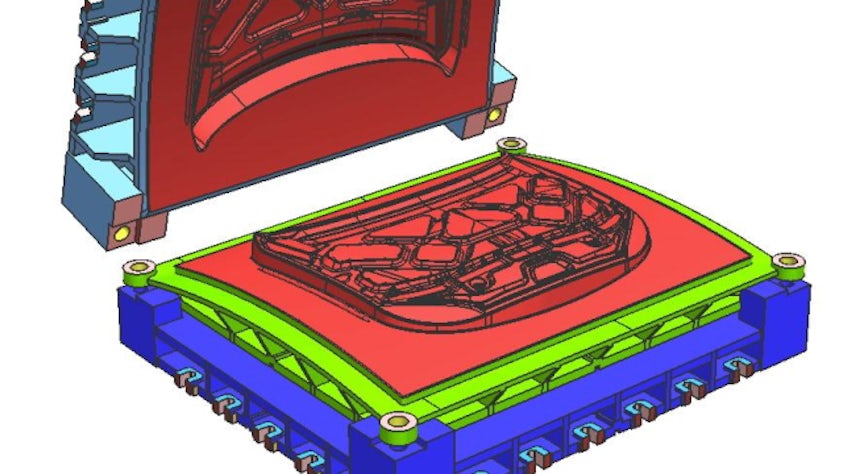

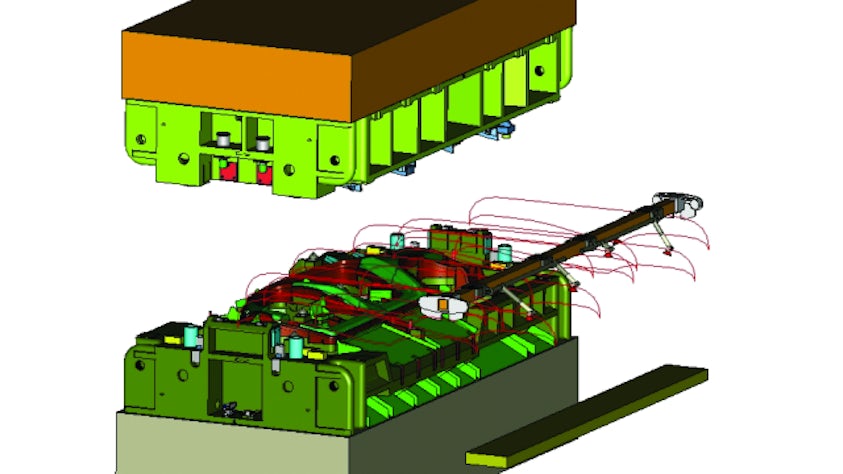

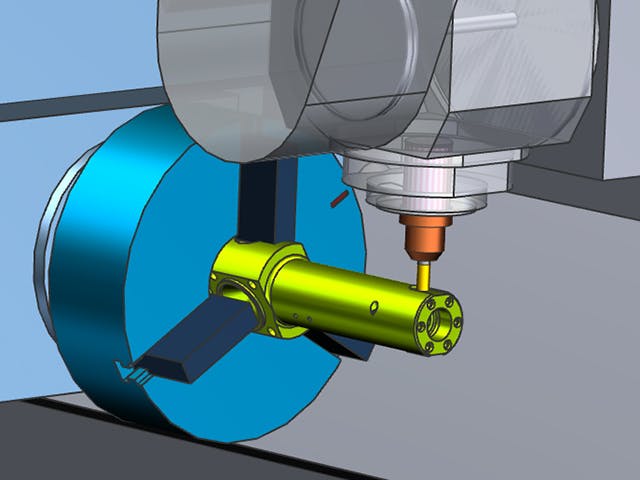

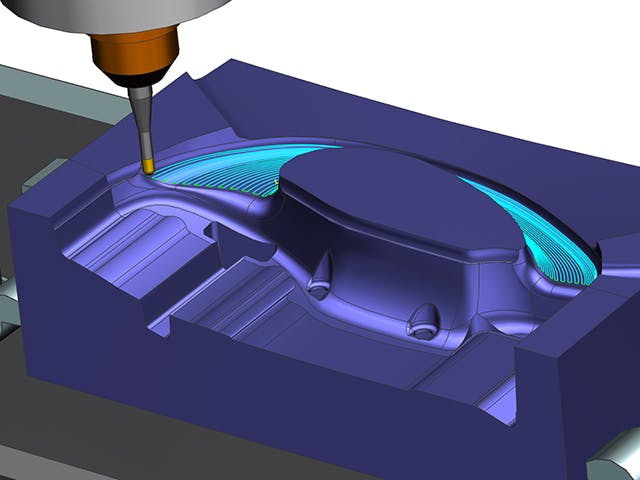

Rapidly create and manipulate complex vehicle body panels with our advanced design and modeling tools. In addition, you can work with data imported from other CAD systems.

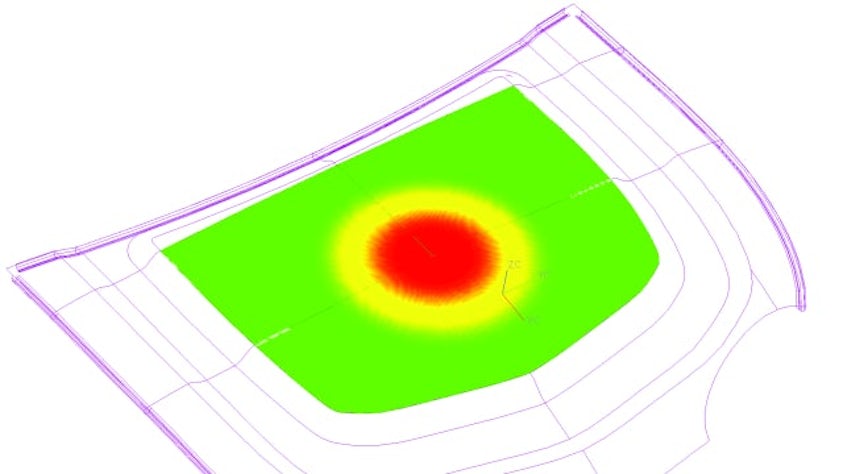

Quickly model sheet metal parts for high-precision automotive applications, easily update models to design changes, and document designs to optimize manufacturing performance.