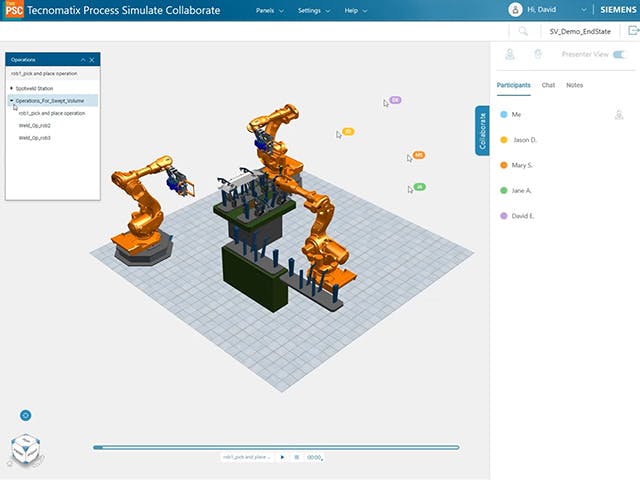

Design complete kinematic workcells

Get access to powerful tools for the design, simulation and validation of manufacturing workcells and processes in a dynamic and highly visual engineering environment.

Author, reuse, validate and optimize process sequences with realistic behavior using fully kinematic 3D models of robots, end-of-arm tooling, fixtures, safety and other automated production system equipment.

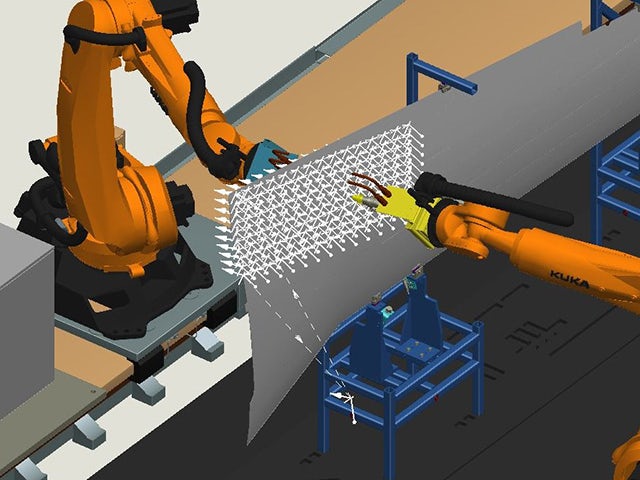

Plan and simulate robotic motion

Create, examine and verify complex robotic motion paths and processes with a complete set of manual and automated robotics simulation software tools.

Facilitate the most realistic discrete and continuous simulation of various manufacturing processes and mechanical procedures for robots, tools and devices, as well as the control logic used to drive them in production.

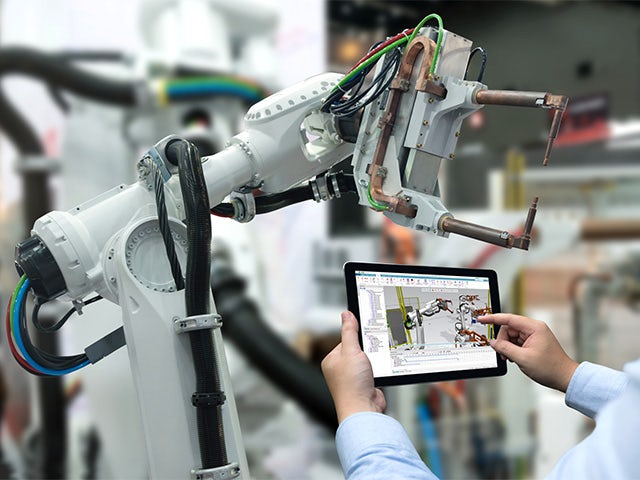

Program robots completely offline

Work with offline robotics programming packages for all major robot brands. Automatically incorporate validated robot paths into fully functional robot programs for download to the physical robot controller, including customer-specific configurations.

Upload programs from the physical robot controller into the software for further robotics simulation, optimization and program maintenance.

Commission production systems virtually

Streamline the flow of data from conceptual design to the shop floor. Leverage a common integration platform for the mechanical and electrical disciplines participating in commissioning of automated production systems.

Simulate real controller code and robot programs combined with actual hardware in a realistic virtual commissioning environment to verify complete system function before starting production.

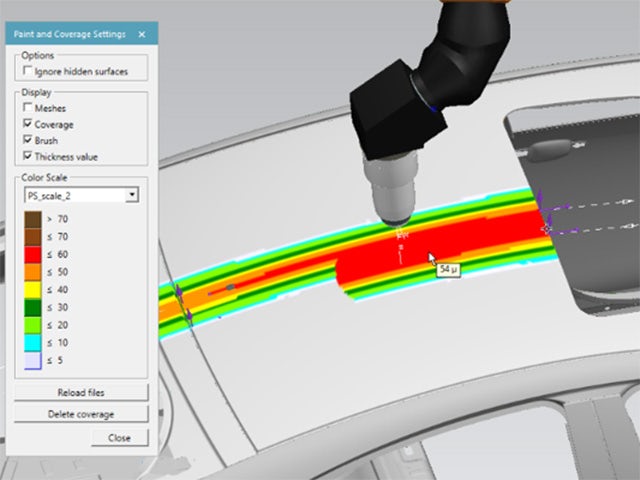

Work with dedicated applications

Utilize process-specific apps and tools for the development and verification of many different manufacturing elements.

Model and simulate assembly, welding, gluing, sealing, spraying and other robotic processes in the same environment to validate complete virtual automated production system zones and advanced manufacturing processes.

Ethos Automation

Ethos uses Tecnomatix software to deliver turnkey solutions to its customers.

Reducing robot programming time by 25 percent

Company:Ethos Automation

Industry:Industrial machinery

Location:Brantford, Ontario, Canada

Siemens Software:Tecnomatix