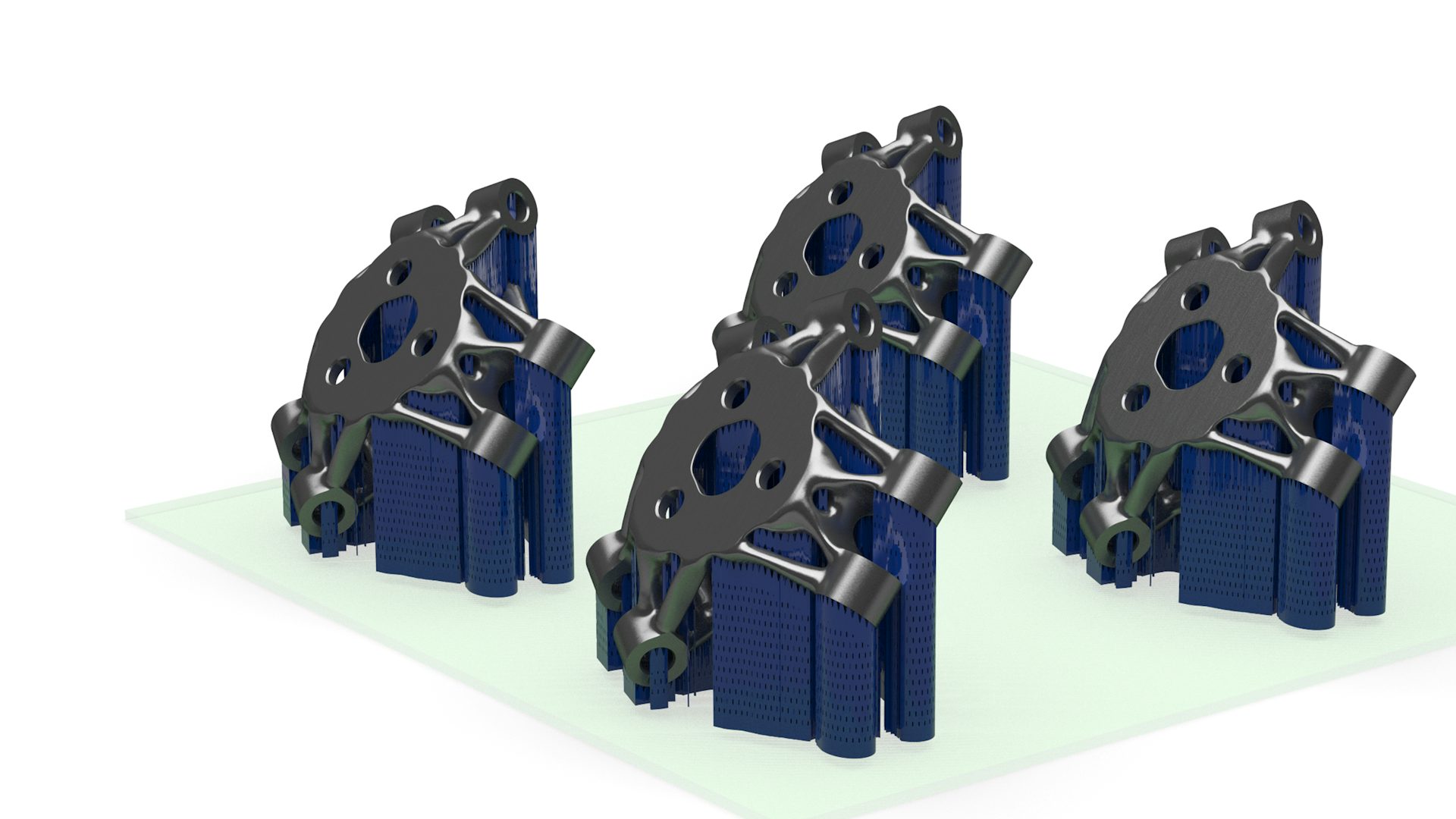

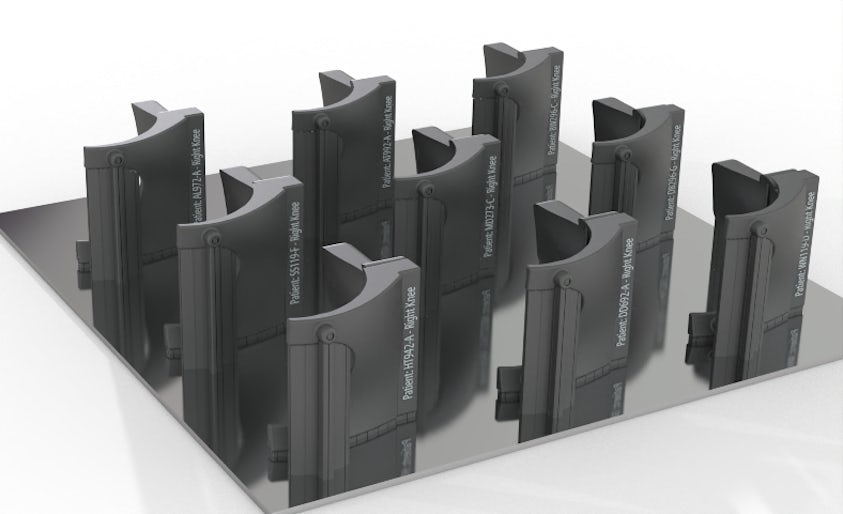

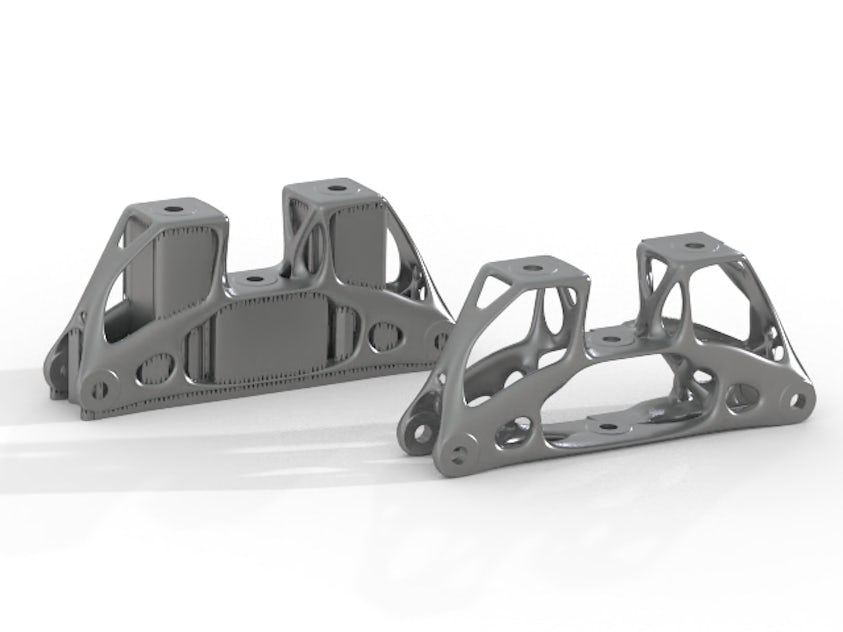

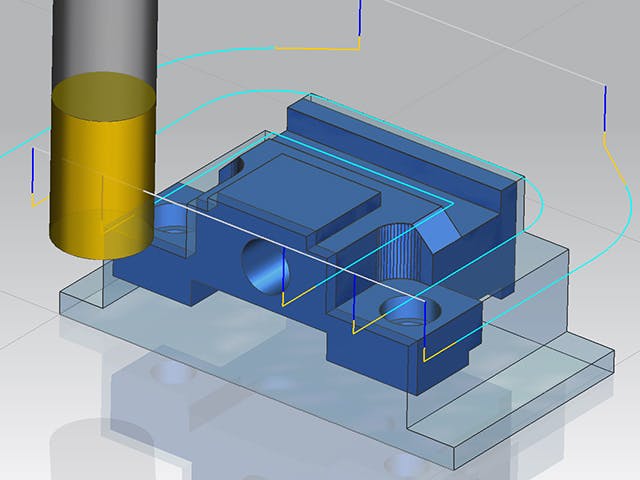

Part placement and nesting

Print parts efficiently with complete control over part position and automated, efficient nesting within the build volume. This is why NX provides integrated tools for efficiently populating the build tray. Whether placing parts manually or automatically via integrated 2D and 3D nesting, NX gives you complete control to achieve efficiency and quality goals.