How do you keep up with the rising complexities of modern ship designs?

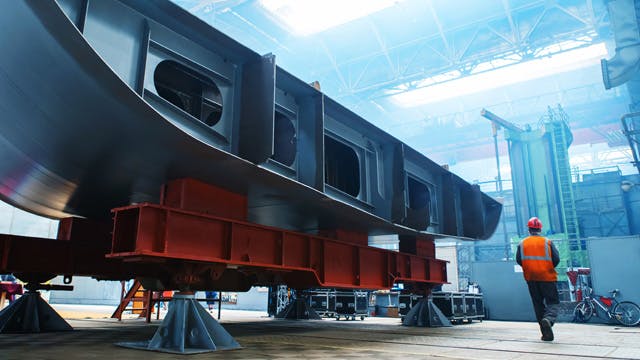

Shipbuilders require design and management systems that can effectively work with enormous amounts of data while enabling the design of entire classes of ships. Remove the barriers of disparate solutions to improve processes and efficiency with the digital twin for a multidisciplinary marine design software approach.

Leverage an end-to-end multidisciplinary ship engineering and manufacturing solution to connect teams with a seamless, integrated flow of information for collaborative and concurrent design for all maritime applications.