Gain a competitive edge with advanced design automation

Wiring harness design

Wiring harness design engineers can effectively capture design intent to create fully detailed and validated harness designs rapidly and accurately.

Wiring harness product engineering

Capital offers automated wire harness engineering, validation and reporting capabilities, enabling harness engineers to efficiently prepare product data.

Wiring harness costing

Capital wiring harness cost modeling enables engineers to create comprehensive models that ensure realistic cost generation and accurate quotations.

Capital helps engineers cut costs and improve quality

Reduce new product introduction times by leveraging digital data continuity and intellectual property (IP) reuse. Optimize designs and improve product quality by applying automation and simulation with digital twin technology.

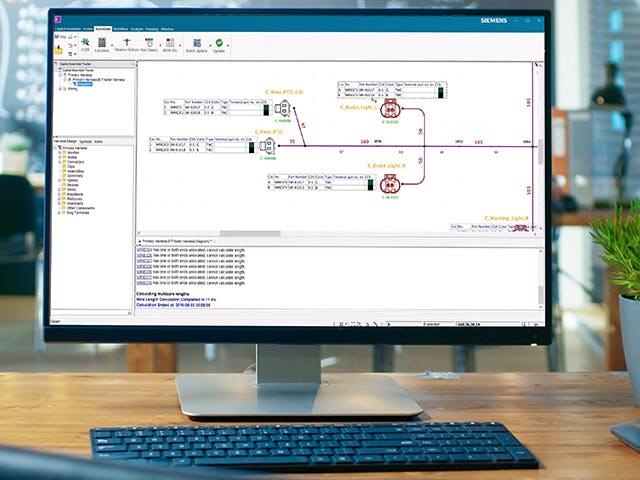

Cost modeling that protects IP

It is vital that harnesses can be manufactured at a competitive and well-understood cost. This is a challenge because project time scales and margins are continually squeezed, while variables such as design content and copper prices can change rapidly. It is a task whose dynamics exceed the grasp of primitive cost calculation methods. Capital offers an optimal, purpose-built solution that automates costing, providing a formal framework and process for the rapid generation of accurate material and labor costing.

Capital includes fully extensible cost modeling that protects IP and enables costing engineers to create comprehensive models. These models capture the necessary detail to ensure realistic cost generation creates accurate quotations. The data becomes a 'digital thread,' allowing the costing models to be consumed and reused by related tools in the manufacturing flow.

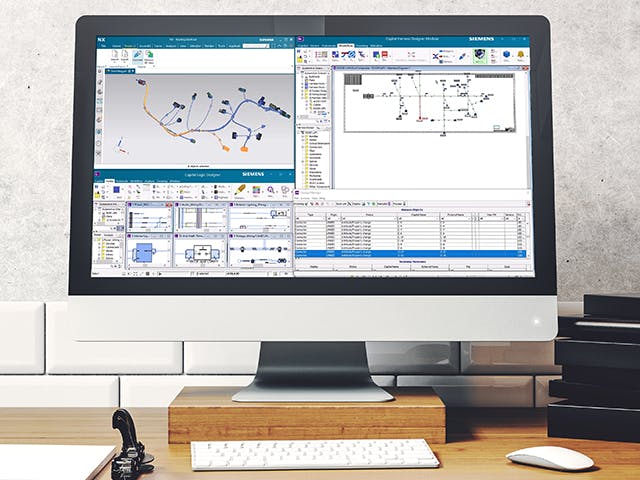

Powerful graphical harness design environment

Harness design engineers need to create a fully detailed drawing that accurately captures and describes the design intent and requirements for a wiring harness. Capital supports all the necessary activities involved in harness design while maintaining digital continuity. It enables companies to tailor the tool and process flow to meet their needs, both in terms of graphical outputs and reports.

Capital offers a powerful graphical harness design environment, enabling automated harness design and validation. Harness design engineers can effectively capture and describe design intent to create fully detailed and validated harness designs (both diagrams and data). Engineers can also define rules and constraints to facilitate comprehensive design automation and ensure consistency.

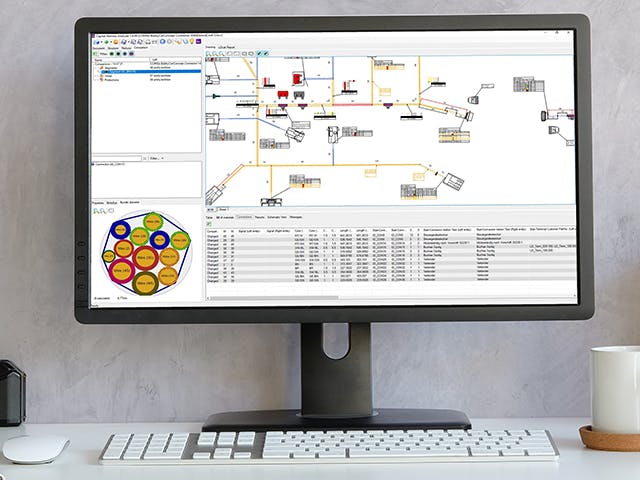

Automated harness product engineering

Harness designs need to be enhanced with relevant details like harness component information and material quantities required for downstream consumption by costing and manufacturing engineering. Harness product engineers aim to fully embellish the design data to achieve a complete and accurate harness definition and extract and deliver related documentation. Automated harness engineering, validation and reporting capabilities enable harness engineers to prepare product data for costing and manufacturing engineering tasks efficiently.

Component selection routines enable the automatic and accurate selection of compatible components to create enhanced harness data for costing and manufacturing. Automated design comparison enables the identification of graphical and specification changes between different product revisions. Automated engineering functionality calculates exact material quantities describing the finished product.

Built to support KBL standard

Capital also includes a leading suite of applications for wiring systems design and wiring harness development based on the KBL standard.

KBL, the data exchange standard used by the German automotive industry, is used in the main development departments of companies, particularly in the German premium automotive sector. Capital includes a suite of products built around this standard, ranging from the import of the first logical system concept to the complete cable set, all the way to production and costing.