Design, optimize and cost manufacturing processes

Harness formboard design

With Capital, formboard designers can create an optimized, ergonomic layout based on dynamic feedback of labor effort/times related to each component.

Wiring harness manufacturing process planning

Use Capital to capture and apply best practice techniques to the wiring harness manufacturing process planning and cost estimation tasks.

Wiring harness manufacturing documentation

The quality of manufacturing documentation is vital to minimize errors in builds. Create manufacturing documentation directly from engineered harness data and the defined assembly process sequence.

Leverage the digital twin to boost productivity

Leverage a digital twin with Capital to transform your company’s engineering, costing and manufacturing performance. Eliminate documentation errors, reducing creation costs and ultimately boosting profits.

Optimize processes and improve wiring harness manufacturing efficiency

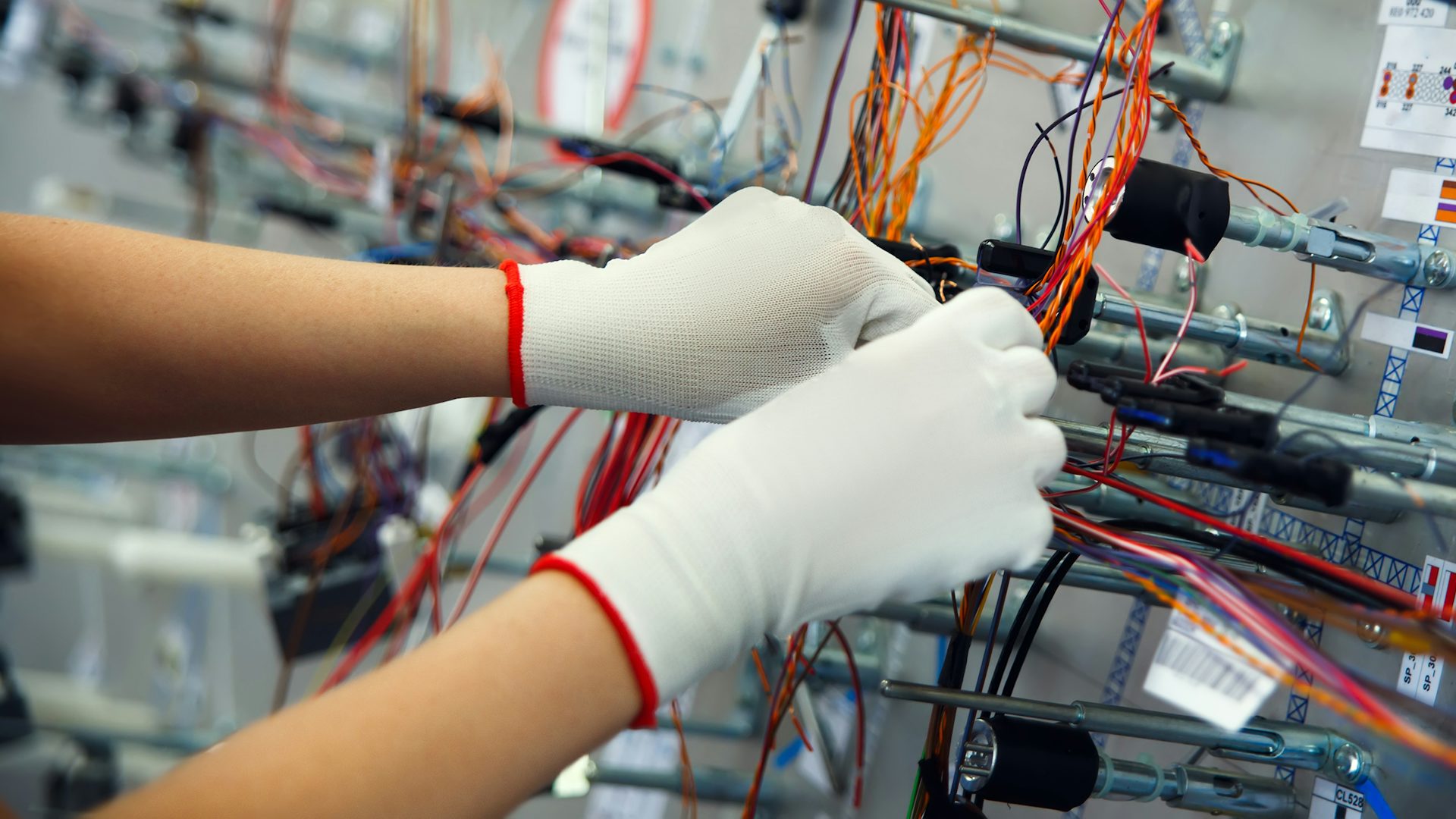

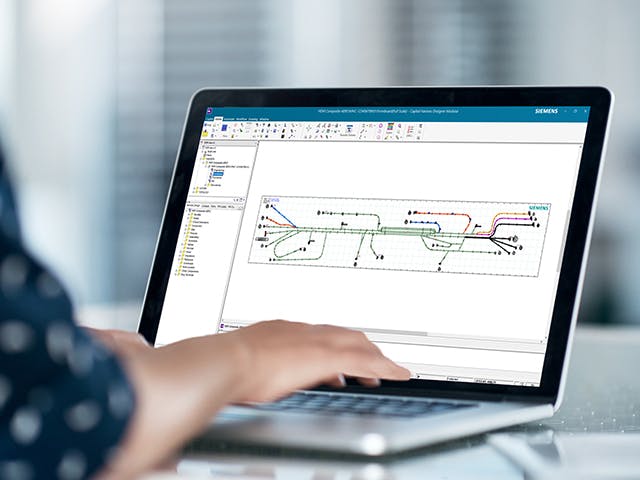

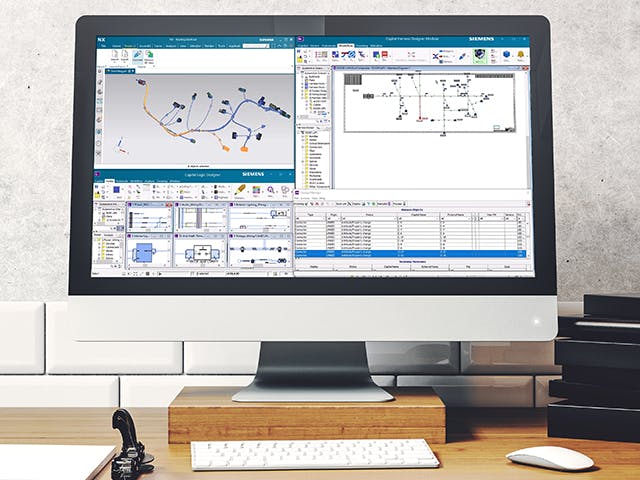

Fully detailed and enhanced harness designs are often documented in a 2D non-scale harness drawing. Manufacturing engineers then use this information to create a full-scale representation of the harness design data, enriched with additional manufacturing information, called a formboard drawing.

In addition to the wire harness components, all manufacturing-relevant objects like bundle forks, connector fixtures, clip holders, and tape position indicators are graphically represented on these formboard drawings, providing visual aids for the operators. The powerful graphical and design-management environment for formboard design within Capital enables manufacturing engineers to rapidly create full-scale, detailed and manufacturing-ready formboard diagrams.

Capital guides formboard designers to create an optimized, ergonomic layout based on dynamic feedback of labor effort/times related to each component as it is placed in a particular zone on the board. Designers can also create and maintain merged or combined formboards for efficient production lines and factory space usage.

Create wiring harness manufacturing documentation

With the complexity of today's harnesses, it is vital to be able to automatically create operator instructions and visual aids for every design and production facility.

The quality of manufacturing documentation is vital to minimize errors in builds. Create documentation directly from engineered harness data and defined assembly process sequences.

Streamline wiring harness manufacturing planning and optimization

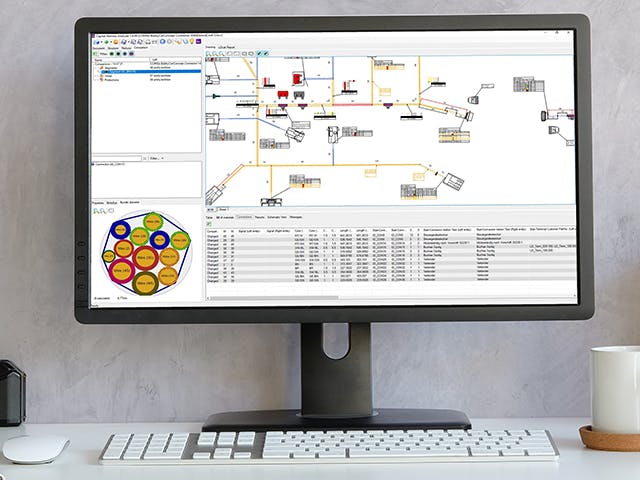

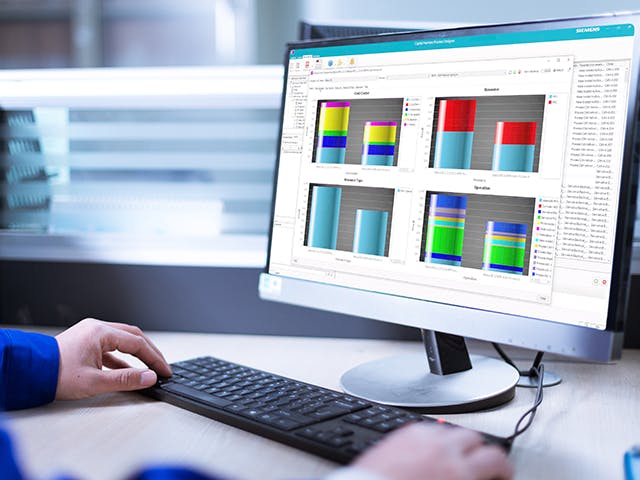

Manufacturing process engineers are often faced with the challenge of determining an efficient pattern of sequenced process steps that result in the correct assembly of the target harness. Usually, more than one possible pattern will exist. The optimum choice depends on the specific manufacturing capabilities of the factory/factories in question. Capital facilitates the automatic creation of an efficient manufacturing scheme for each harness to be built. This is achieved by decomposing harness designs against previously captured descriptions of manufacturing capabilities, using a reasoning engine that incorporates wire harness assembly logic.

Engineers can use Capital to capture and apply best practice techniques to manufacturing process planning and cost estimation tasks. It facilitates fast and accurate process planning, allowing engineers more time to create multiple "what if" scenarios to be compared with each other and analyzed for optimum manufacturing efficiency. Manufacturing engineers can leverage capabilities offered by Capital to design efficient production lines, use existing manufacturing resources as effectively as possible, and react quickly to new situations like changed take rates. It helps inform better shop floor decisions and ultimately reduces the time to profitability.