Collaborate and validate across domains

Fully manage the entire electronic design cycle from schematic capture to manufacturing - in alignment with mechanical and simulation engineers. Improve engineering productivity for ECAD. Find, share and re-use electrical and electronic CAD data in a fully integrated, multi-domain PLM environment.

Manage schematic and printed circuit board (PCB) data

Integrate your global electronics design teams and suppliers by bringing together native design data in a single system. Work in your preferred ECAD tool with easy access to Teamcenter. Find the correct data quickly and eliminate inconsistency with an enterprise-wide ECAD parts library inside PLM. Leverage integrations with Altium Designer, Cadence Allegro and OrCAD, and Siemens Xpedition and PADS.

Manage wire harness and electrical distribution systems

Teamcenter supports the inception, creation, analysis, manufacturing, service and end-of-life disposition of electrical distribution systems with Capital, Capital Essentials, AutoCAD Electrical integrations. Leverage the full power of PLM with integrated mechanical design, simulation, requirements, workflow, configuration and change control, to improve quality, accelerate time-to-market and cut development cost.

Collaborate on a complete design across domains

Create a single bill of materials (BOM) for your entire product – from electrical harness, PCB, PCB components to mechanical design and software. A common library between domains means that a single component has both electrical/electronic and mechanical data. The details are there when you need them, and when something changes, you can see that change in real time to understand the impact.

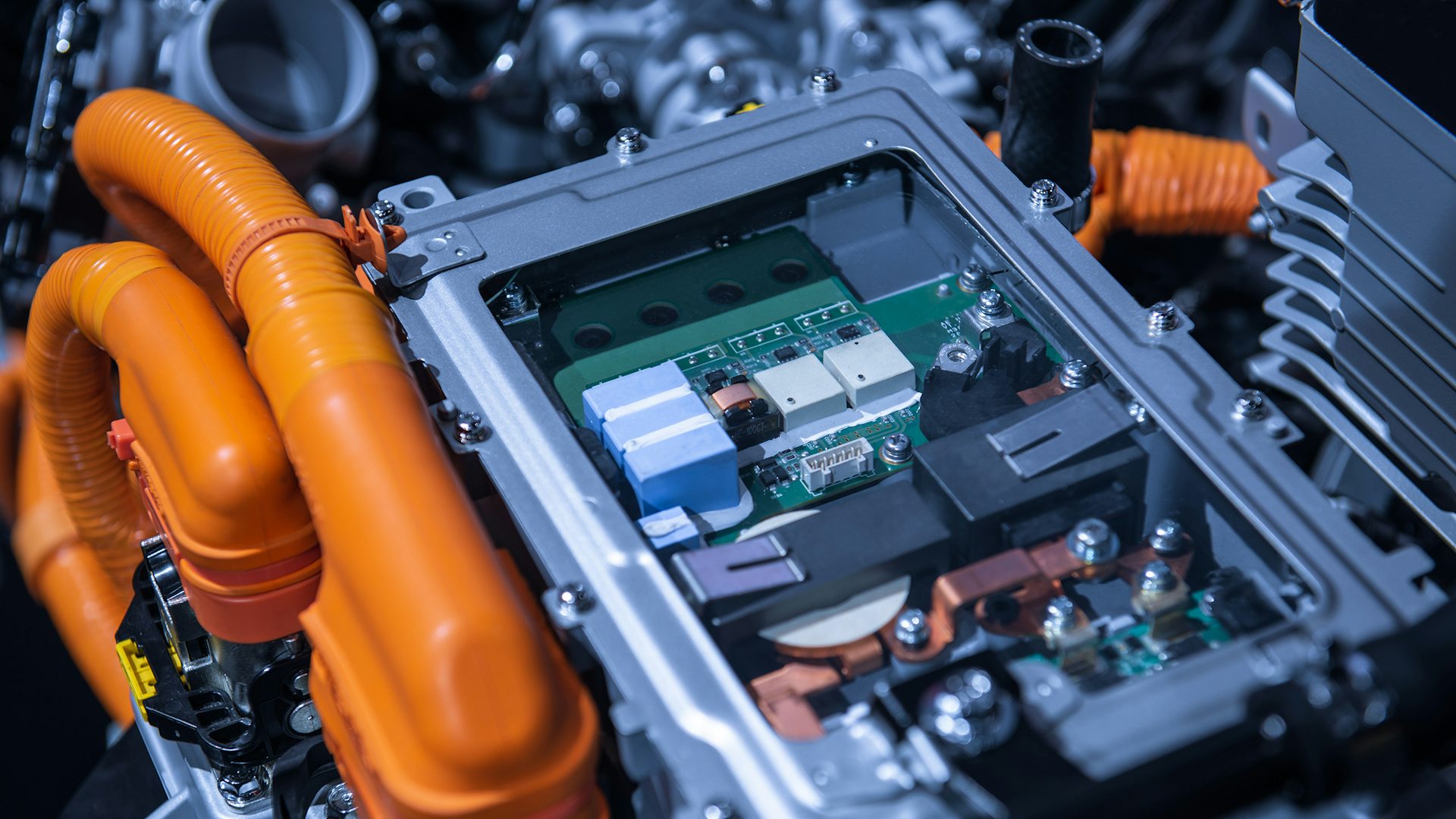

Connect electronic/electrical design with manufacturing

Ensure a seamless exchange with manufacturing with fully integrated electronic and electrical CAD management in Teamcenter. Automate manufacturing outputs, verify design manufacturability, automate supplier collaboration and fully integrate change control. Share a multi-domain bill of materials (BOM) to help bridge the gap between manufacturing and engineering.

Teradyne

Teradyne takes charge of complex product development

Company:Teradyne

Location:Massachusetts, USA