Find what you need faster with search and analytics

Find the information you need without a lot of effort: Today's products require an enormous amount of data. Dashboards, reports and smart, connected data help you find the information you need – fast.

Enjoy data management that works with you

Experience transparent and connected data in an easy to use environment with smart user interaction in Teamcenter. Connected data and processes means relevant information is at your fingertips – no search required! The user interface naturally guides you to what you need with minimal effort.

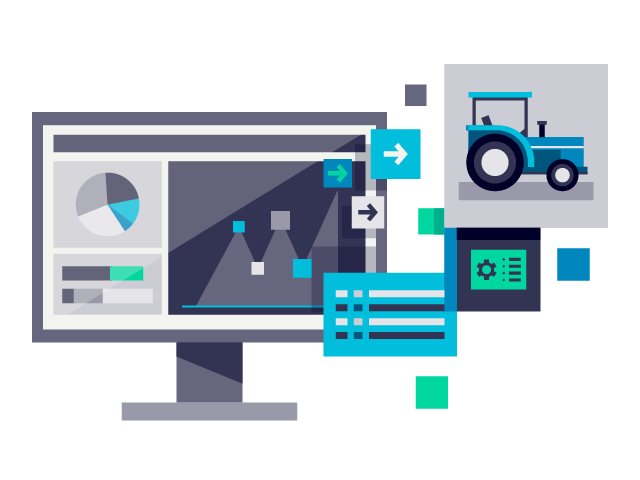

Understand the big picture and take action

Cut through the clutter to turn data into knowledge. Choose from more than 100 pre-configured out-of-the-box reports or create your own. Self-service analytics enable you to use natural language to create on-demand reports of the information you need. These reports understand and connect to the business model in Teamcenter, so all rules apply, security is enforced, and you can directly act on that information.

Find what you need with information you have

Search with whatever information you have, in whatever format you have it – intuitively and naturally. The search function in Teamcenter really understands your products – from its attributes and relationships, all the way down to its geometry. So, find information easier – all of the time!

Classify and reuse

Organize any product data, from parts and documents to marketing and brand data, with Teamcenter classification. It's easy to filter on characteristics or browse the classification structure to find what you need. Define your own hierarchy and characteristics or leverage ECLASS common classification standards. These standards make the exchange of data across organizations easier with unambiguous data semantics.